MIG/MAG WELDING SYSTEMS

COMMON FEATURES

Large control elements for optimum adjustment Copper coil with heat protection for long service life Welding wire holder for 0.8 kg and 5 kg rolls Mobile for easy transportation

Variable gas bottle holder

5 year warranty on main transformer

....5 year warranty

on main transformer

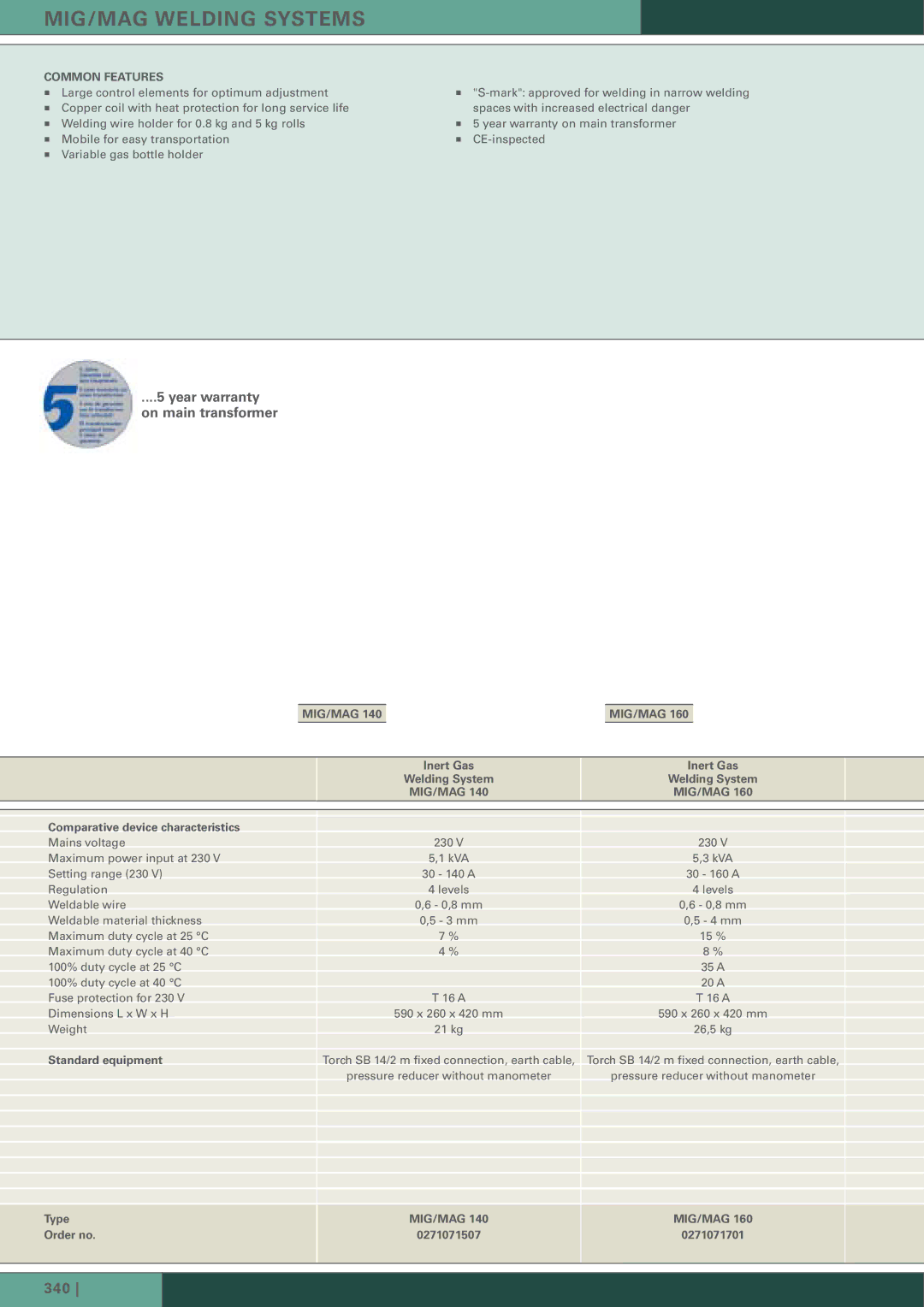

MIG/MAG 140 |

| MIG/MAG 160 |

Comparative device characteristics

Inert Gas | Inert Gas |

Welding System | Welding System |

MIG/MAG 140 | MIG/MAG 160 |

Mains voltage

Maximum power input at 230 V Setting range (230 V) Regulation

Weldable wire

Weldable material thickness Maximum duty cycle at 25 °C Maximum duty cycle at 40 °C 100% duty cycle at 25 °C 100% duty cycle at 40 °C Fuse protection for 230 V Dimensions L x W x H Weight

Standard equipment

Type

Order no.

230V 5,1 kVA

30 - 140 A

4levels 0,6 - 0,8 mm 0,5 - 3 mm 7 %

4 %

T 16 A

590 x 260 x 420 mm

21 kg

Torch SB 14/2 m fixed connection, earth cable,

pressure reducer without manometer

MIG/MAG 140

0271071507

230V 5,3 kVA

30 - 160 A

4levels 0,6 - 0,8 mm 0,5 - 4 mm 15 %

8 %

35 A

20 A

T 16 A

590 x 260 x 420 mm

26,5 kg

Torch SB 14/2 m fixed connection, earth cable,

pressure reducer without manometer

MIG/MAG 160

0271071701

340