Maxstar 150 STL | Issued February 2008 • Index No. DC/27.1 | ||

| ® |

| TIG/Stick Welding |

|

|

| Power Source |

| Light Industrial Applications | Processes | Amperage Range 115 VAC: 5 – 150 A (DC TIG) |

| |||

Quick | Process Piping | 20 – 100 A (DC Stick) | |

Dairy Industry | Stick (SMAW) | 230 VAC: 5 – 150 A (DC TIG) | |

Food/Beverage Industry | Input Power | 20 – 150 A (DC Stick) | |

Specs | Restaurant/Kitchen Repair | Max. | |

Experimental Aircraft | |||

| Shipboard Installation/Repair |

| |

|

| Weight 13.7 lb (6.2 kg) | |

| Maintenance Repair |

| |

|

|

| |

® |

| New Case and | |

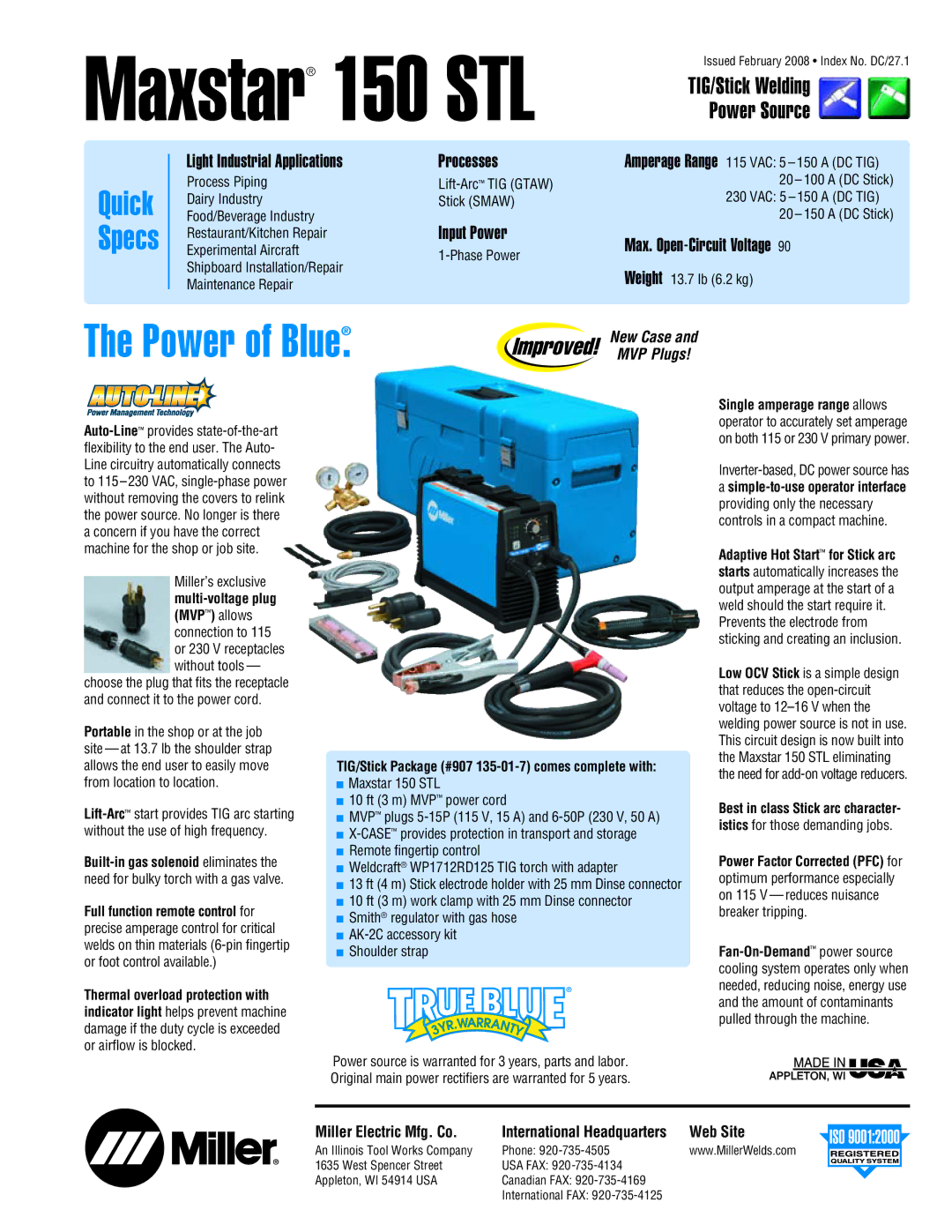

The Power of Blue. | Improved! | ||

MVP Plugs! |

Miller’s exclusive

choose the plug that fits the receptacle and connect it to the power cord.

Portable in the shop or at the job site — at 13.7 lb the shoulder strap allows the end user to easily move from location to location.

Full function remote control for precise amperage control for critical welds on thin materials

Thermal overload protection with indicator light helps prevent machine damage if the duty cycle is exceeded or airflow is blocked.

TIG/Stick Package (#907 ![]() Maxstar 150 STL

Maxstar 150 STL

![]() 10 ft (3 m) MVP™ power cord

10 ft (3 m) MVP™ power cord

![]() MVP™ plugs

MVP™ plugs

![]()

![]() Remote fingertip control

Remote fingertip control

![]() Weldcraft® WP1712RD125 TIG torch with adapter

Weldcraft® WP1712RD125 TIG torch with adapter

![]() 13 ft (4 m) Stick electrode holder with 25 mm Dinse connector

13 ft (4 m) Stick electrode holder with 25 mm Dinse connector

![]() 10 ft (3 m) work clamp with 25 mm Dinse connector

10 ft (3 m) work clamp with 25 mm Dinse connector

![]() Smith® regulator with gas hose

Smith® regulator with gas hose ![]()

Shoulder strap

Shoulder strap

Power source is warranted for 3 years, parts and labor. Original main power rectifiers are warranted for 5 years.

Single amperage range allows operator to accurately set amperage on both 115 or 230 V primary power.

Adaptive Hot Start™ for Stick arc starts automatically increases the output amperage at the start of a weld should the start require it.

Prevents the electrode from sticking and creating an inclusion.

Low OCV Stick is a simple design that reduces the

Best in class Stick arc character- istics for those demanding jobs.

Power Factor Corrected (PFC) for optimum performance especially on 115 V — reduces nuisance breaker tripping.

Miller Electric Mfg. Co. | International Headquarters | Web Site |

An Illinois Tool Works Company | Phone: | www.MillerWelds.com |

1635 West Spencer Street | USA FAX: |

|

Appleton, WI 54914 USA | Canadian FAX: |

|

| International FAX: |

|