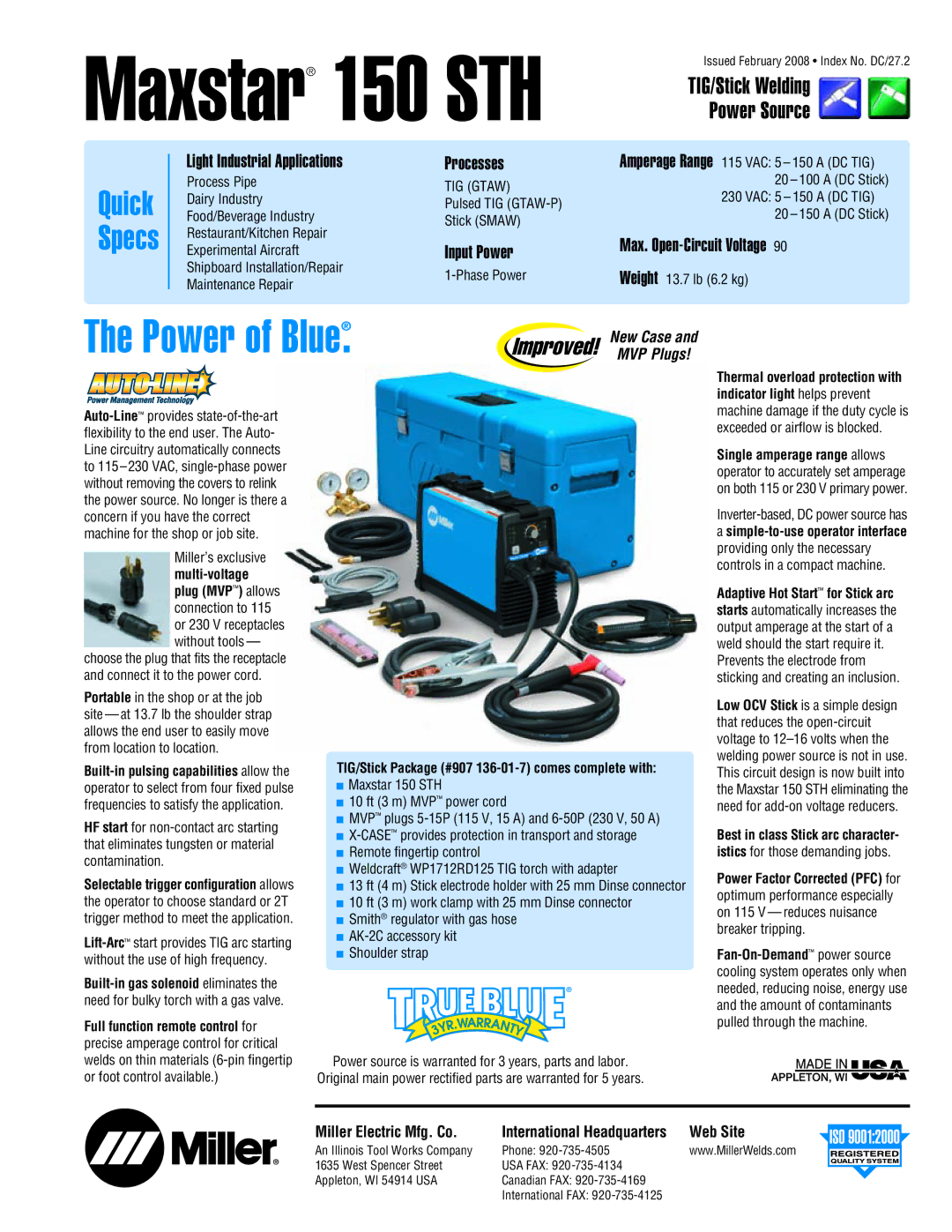

150STH specifications

Miller Electric's 150STH is a compact and versatile welding machine designed to cater to the needs of both professionals and hobbyists in the welding industry. This MIG welder is particularly well-suited for thin materials, making it an excellent choice for automotive repair, light fabrication, and maintenance tasks.One of the standout features of the 150STH is its impressive weight-to-power ratio. Weighing in at just around 40 pounds, it is lightweight and portable, allowing users to easily transport it to different job sites or move it around the workshop. This portability does not come at the cost of performance, as the welder can accommodate a range of welding tasks with its power output capabilities.

The Miller 150STH is equipped with advanced inverter technology, enhancing its efficiency and energy consumption. This technology allows the machine to provide a stable arc while reducing power loss, which is particularly beneficial for extended welding sessions. Furthermore, the inverter design contributes to a smaller footprint compared to traditional welding machines, making it an ideal fit for tight spaces.

A user-friendly interface is another hallmark of the Miller 150STH. The welder features easily adjustable settings, enabling welders to quickly dial in the required voltage and wire feed speed for various applications. The intuitive controls are suitable for both novice and experienced welders, ensuring a smooth learning curve for beginners while allowing seasoned professionals to execute precise welds.

Safety is always a top priority in welding, and the Miller 150STH addresses this concern with its built-in safety features. The machine is designed with thermal overload protection, which automatically shuts down the unit if it starts to overheat. This function helps prolong the life of the welder and ensures user safety during operation.

Versatility is a key characteristic of the 150STH. It is compatible with solid and flux-cored welding wires, giving users the flexibility to choose the best wire type for their specific job. Additionally, the welder can work with various metal thicknesses, making it a well-rounded piece of equipment for a wide range of projects.

In summary, the Miller Electric 150STH is a powerful, portable, and user-friendly welding machine equipped with advanced inverter technology, safety features, and the versatility needed to tackle diverse welding applications. Whether for professional use or personal projects, the 150STH stands out as a reliable and efficient choice for welders at any skill level.