350 Series specifications

Miller Electric's 350 Series represents a pinnacle of innovation and reliability in the welding industry, focusing on advanced technologies that enhance performance and efficiency across various applications. This series is designed to meet the demands of both professionals and industrial environments while offering a robust solution for various welding processes including MIG, TIG, and Stick.One of the standout features of the Miller Electric 350 Series is its intuitive Auto-Set technology. This feature automatically adjusts the welding parameters based on the selected process, material thickness, and wire type, reducing the time and effort spent on setup. This not only ensures optimal results but also minimizes the potential for errors, making it an ideal choice for both seasoned welders and beginners.

Another key characteristic of the 350 Series is its durability and portability. Constructed with rugged components, these machines are built to withstand the rigors of a demanding work environment. The design incorporates a lightweight and compact form, allowing for easy transport to job sites. This is particularly beneficial for contractors and professionals who frequently move between different locations.

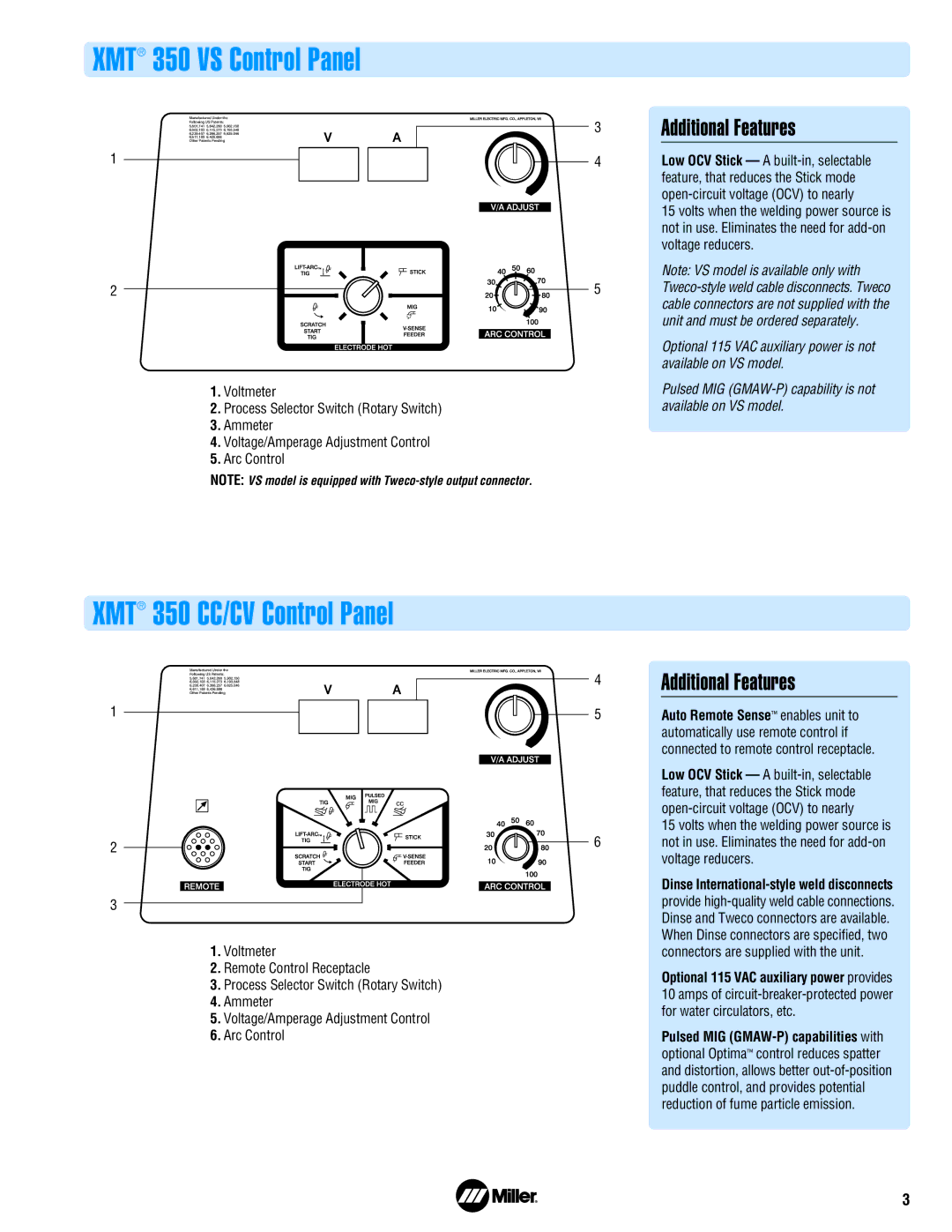

The 350 Series also features advanced digital monitoring systems that provide real-time feedback on performance. This includes indicators such as voltage, amperage, and wire feed speed, enabling users to make precise adjustments during the welding process. Enhanced control contributes to greater consistency and quality in welds, which is paramount in industrial applications where precision is critical.

Moreover, the Miller Electric 350 Series incorporates Power Factor Correction (PFC) technology, which boosts efficiency and reduces energy consumption. This feature not only lowers electricity costs but also minimizes the need for large generators, further enhancing the portability of the unit.

Safety is another area where the 350 Series shines. It is equipped with various safety features, including over-temperature protection and fault indicators, ensuring that users can operate the machines with confidence.

In summary, Miller Electric's 350 Series combines advanced technologies, ease of use, and durable design to provide a comprehensive welding solution that meets the needs of various professionals in the industry. Whether for heavy industrial work or lighter applications, the 350 Series stands ready to deliver outstanding performance and reliability.