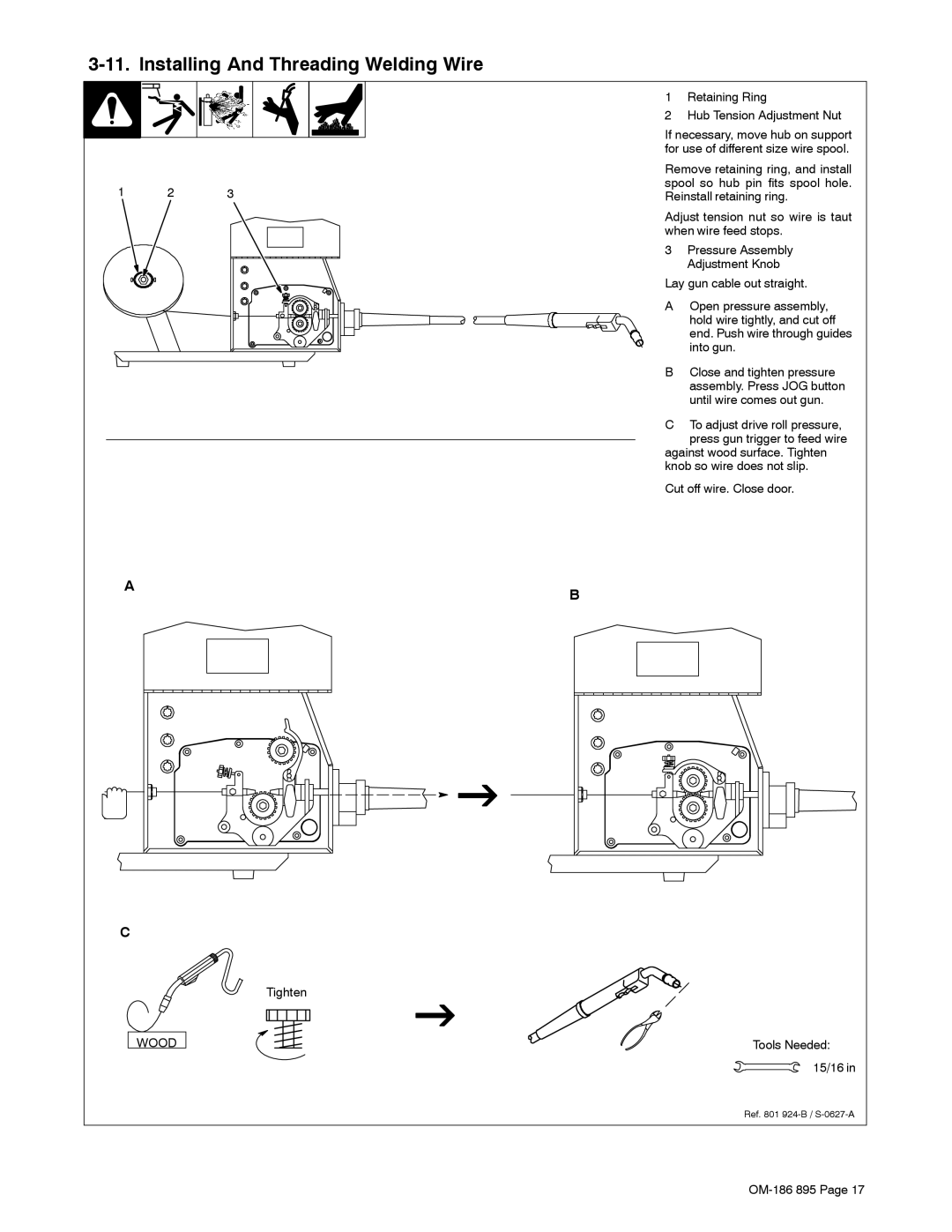

3-11. Installing And Threading Welding Wire

1 2 3

1Retaining Ring

2Hub Tension Adjustment Nut

If necessary, move hub on support for use of different size wire spool.

Remove retaining ring, and install spool so hub pin fits spool hole. Reinstall retaining ring.

Adjust tension nut so wire is taut when wire feed stops.

3Pressure Assembly Adjustment Knob

Lay gun cable out straight.

AOpen pressure assembly, hold wire tightly, and cut off end. Push wire through guides into gun.

BClose and tighten pressure assembly. Press JOG button until wire comes out gun.

CTo adjust drive roll pressure,

press gun trigger to feed wire against wood surface. Tighten knob so wire does not slip.

Cut off wire. Close door.

AB

C

Tighten

WOOD | Tools Needed: |

15/16 in

Ref. 801