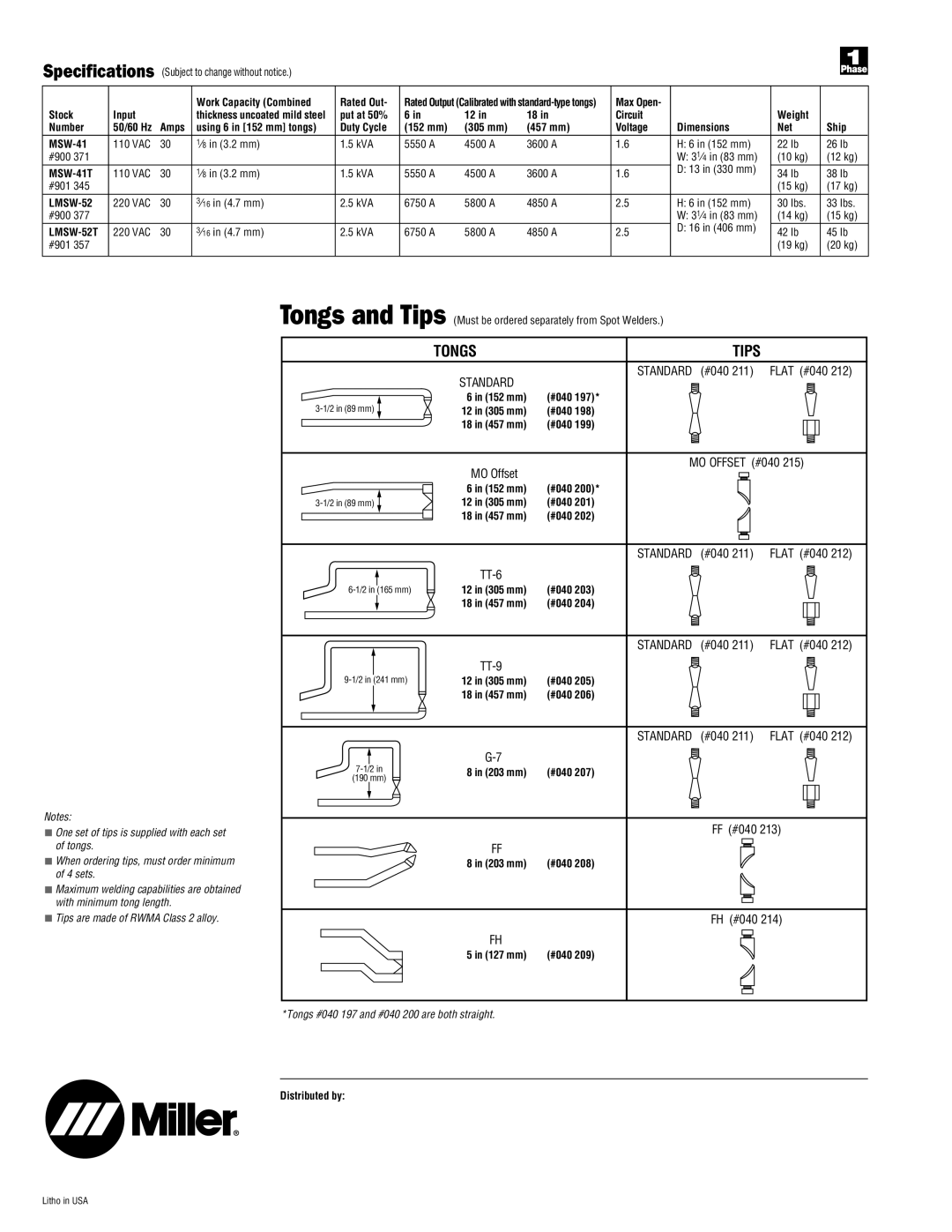

MSW, LMSW Series specifications

Miller Electric’s LMSW Series, MSW is a cutting-edge line of welding machines designed for maximum efficiency and versatility in various industrial applications. With a reputation for durability and performance, the LMSW Series combines advanced technologies with practical features to meet the evolving needs of welders.One of the most notable characteristics of the LMSW Series is its user-friendly interface. The machine features a digital display that allows operators to easily adjust settings such as voltage, wire speed, and amperage. This helps ensure precise control over the welding process, leading to consistent weld quality. The intuitive design also minimizes the learning curve for new users, making it an excellent choice for both seasoned professionals and those new to welding.

In terms of technology, the LMSW Series incorporates Miller’s proprietary Auto-Set feature, which automatically selects optimal parameters based on the material thickness and type. This intelligent adjustment capability saves time and reduces the chances of operator error, enhancing overall productivity. Additionally, the machines are equipped with advanced inverter technology, which provides higher power efficiency and a lightweight design, making them easier to transport to job sites.

The LMSW Series also features a robust construction, built to withstand the rigors of daily use in demanding environments. With an IP23 rating, these machines are resistant to dust and moisture, ensuring reliable performance in challenging conditions. Coupled with solid metal casing and premium components, these welders are built to last.

Furthermore, the LMSW Series offers multiple welding processes, including MIG, TIG, and stick welding, making it a versatile tool for various applications. This flexibility accommodates a wide range of materials such as steel, stainless steel, and aluminum, allowing users to tackle diverse projects without needing multiple machines.

Another standout feature of the LMSW is its energy-efficient design, which not only contributes to lower operational costs but also aligns with growing sustainability standards in manufacturing. This eco-conscious approach does not compromise on power or output, making it an ideal choice for businesses looking to improve their environmental footprint while maintaining high-quality work.

In summary, Miller Electric's LMSW Series, MSW stands out in the welding equipment market due to its user-friendly interface, cutting-edge technologies like Auto-Set and inverter design, robust construction, versatile welding processes, and energy efficiency. These characteristics make it a reliable choice for professionals in need of a machine that combines power, precision, and adaptability, ensuring that it meets the demands of both today and tomorrow’s welding challenges.