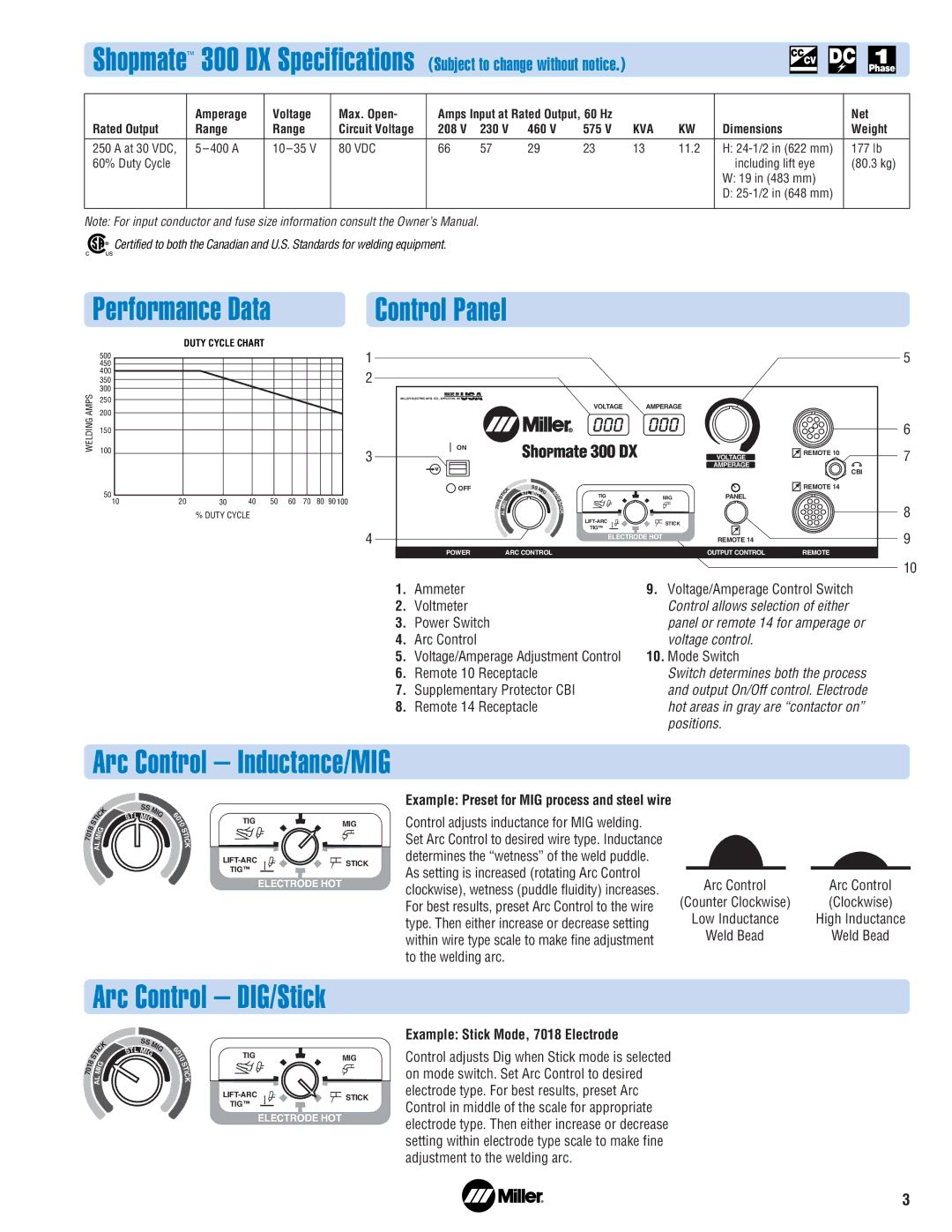

Shopmate™ 300 DX Specifications | (Subject to change without notice.) |

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

| ||||||

| Amperage | Voltage | Max. Open- | Amps Input at Rated Output, 60 Hz |

|

|

|

|

|

| Net | ||||||

Rated Output | Range | Range | Circuit Voltage | 208 V | 230 V | 460 V | 575 V | KVA | KW | Dimensions | Weight | ||||||

|

|

|

|

|

|

|

|

|

|

|

| ||||||

250 A at 30 VDC, | 5 – 400 A | 10 – 35 V | 80 VDC | 66 | 57 | 29 | 23 | 13 | 11.2 | H: | 177 lb | ||||||

60% Duty Cycle |

|

|

|

|

|

|

|

|

| including lift eye | (80.3 kg) | ||||||

|

|

|

|

|

|

|

|

|

| W: 19 in (483 mm) |

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| D: |

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: For input conductor and fuse size information consult the Owner’s Manual.

![]() Certified to both the Canadian and U.S. Standards for welding equipment.

Certified to both the Canadian and U.S. Standards for welding equipment.

Performance Data | Control Panel |

DUTY CYCLE CHART |

|

| 500 |

|

|

|

|

|

|

| 1 |

| 450 |

|

|

|

|

|

|

| |

| 400 |

|

|

|

|

|

|

| 2 |

| 350 |

|

|

|

|

|

|

| |

AMPS | 300 |

|

|

|

|

|

|

|

|

250 |

|

|

|

|

|

|

|

| |

200 |

|

|

|

|

|

|

|

| |

WELDING | 150 |

|

|

|

|

|

|

|

|

100 |

|

|

|

|

|

|

| 3 | |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| |

| 50 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 100 |

| 10 |

% DUTY CYCLE

4

ON

![]() OFF

OFF

POWER

|

|

|

|

| SS |

|

| |

|

|

|

| K |

| M |

| 6 |

|

| C | TL M | IG | G | 0 | ||

| T | I |

|

| S |

| 1 | |

|

|

|

|

|

|

| 0 | |

8 | S |

| G |

|

|

|

| S |

1 |

|

|

|

|

|

| T | |

0 |

| I |

|

|

|

| I | |

7 |

| M |

|

|

|

|

| C |

| L |

|

|

|

|

| K | |

| A |

|

|

|

|

|

| |

ARC CONTROL

|

|

|

| 5 |

VOLTAGE | AMPERAGE |

|

|

|

|

|

|

| 6 |

|

| VOLTAGE | REMOTE 10 | 7 |

|

|

| ||

|

| AMPERAGE |

| CBI |

|

|

|

| |

|

|

| REMOTE 14 |

|

TIG | MIG | PANEL |

|

|

|

|

| 8 | |

STICK |

|

|

| |

TIG™ |

|

|

| |

|

|

| 9 | |

ELECTRODE HOT | REMOTE 14 |

| ||

|

|

| ||

|

| OUTPUT CONTROL | REMOTE |

|

|

|

|

| 10 |

1. | Ammeter | 9. Voltage/Amperage Control Switch |

2. | Voltmeter | Control allows selection of either |

3. | Power Switch | panel or remote 14 for amperage or |

4. | Arc Control | voltage control. |

5. | Voltage/Amperage Adjustment Control | 10. Mode Switch |

6. | Remote 10 Receptacle | Switch determines both the process |

7. | Supplementary Protector CBI | and output On/Off control. Electrode |

8. | Remote 14 Receptacle | hot areas in gray are “contactor on” |

|

| positions. |

Arc Control – Inductance/MIG

|

| K | L | SS | MI |

|

|

| |

|

|

| 6 |

|

| ||||

|

| IC | MI |

| G |

|

| ||

|

| ST |

|

| 0 |

|

| ||

| T |

|

| G |

| 1 | TIG | MIG | |

|

|

|

|

|

| 0 | |||

8 | S | IG |

|

|

|

| S |

| |

1 |

|

|

|

|

| T |

|

| |

0 |

| M |

|

|

|

| I |

|

|

7 |

|

|

|

|

| C |

|

| |

| L |

|

|

|

| K |

|

| |

| A |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| ||

STICK | ||

TIG™ | ||

|

ELECTRODE HOT

ARC CONTROL

Example: Preset for MIG process and steel wire

Control adjusts inductance for MIG welding. Set Arc Control to desired wire type. Inductance determines the “wetness” of the weld puddle. As setting is increased (rotating Arc Control clockwise), wetness (puddle fluidity) increases. For best results, preset Arc Control to the wire type. Then either increase or decrease setting within wire type scale to make fine adjustment to the welding arc.

Arc Control | Arc Control |

(Counter Clockwise) | (Clockwise) |

Low Inductance | High Inductance |

Weld Bead | Weld Bead |

Arc Control – DIG/Stick

|

| K | L | SS | MI |

|

|

| |

|

|

| 6 |

|

| ||||

|

| IC | MI |

| G |

|

| ||

|

| ST |

|

| 0 |

|

| ||

| T |

|

| G |

| 1 | TIG | MIG | |

|

|

|

|

|

| 0 | |||

8 | S | IG |

|

|

|

| S |

| |

1 |

|

|

|

|

| T |

|

| |

0 |

| M |

|

|

|

| I |

|

|

7 |

|

|

|

|

| C |

|

| |

| L |

|

|

|

| K |

|

| |

| A |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| ||

STICK | ||

TIG™ | ||

|

ELECTRODE HOT

ARC CONTROL

Example: Stick Mode, 7018 Electrode

Control adjusts Dig when Stick mode is selected on mode switch. Set Arc Control to desired electrode type. For best results, preset Arc Control in middle of the scale for appropriate electrode type. Then either increase or decrease setting within electrode type scale to make fine adjustment to the welding arc.

3