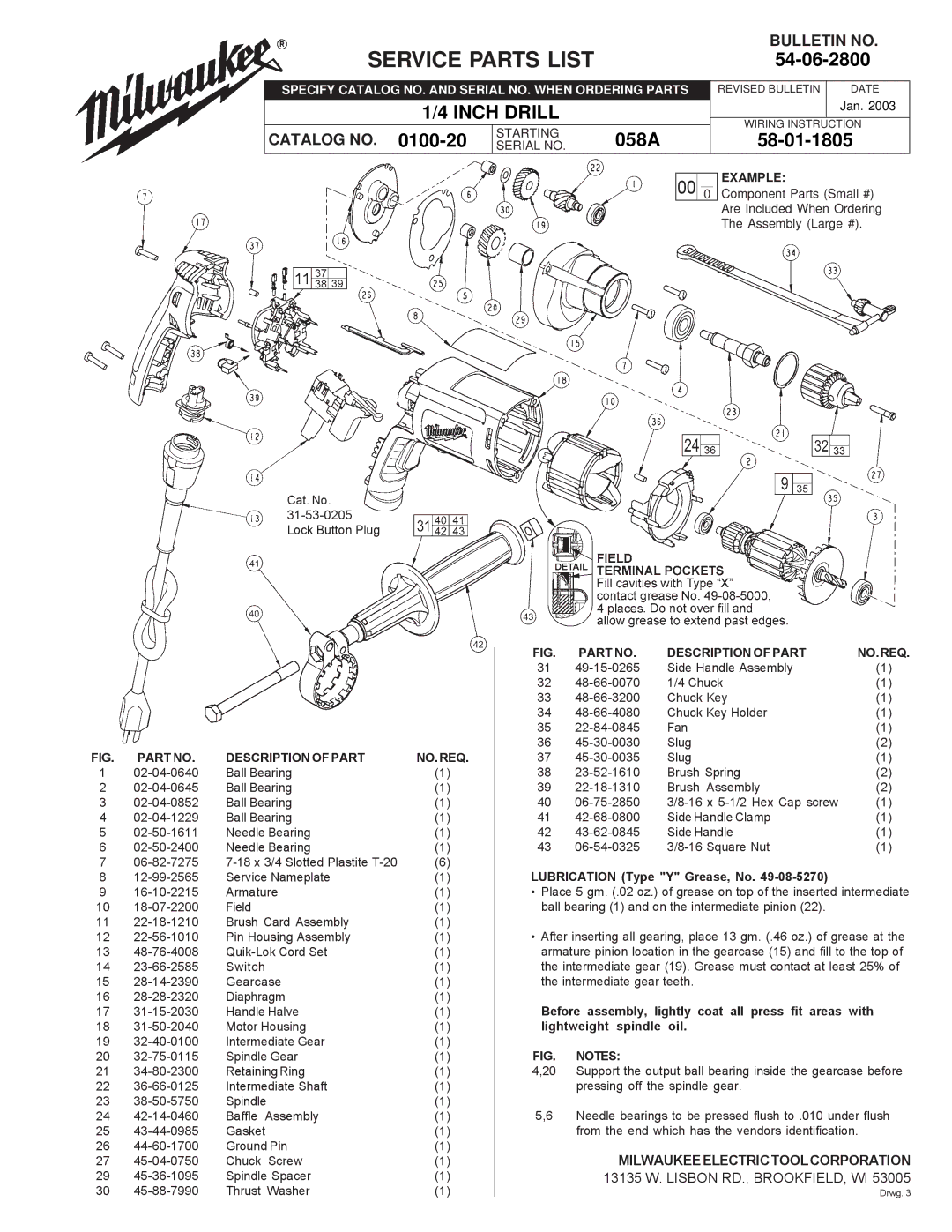

SERVICE PARTS LIST

BULLETIN NO.

54-06-2800

SPECIFY CATALOG NO. AND SERIAL NO. WHEN ORDERING PARTS

1/4 INCH DRILL

CATALOG NO. | STARTING | 058A |

SERIAL NO. |

REVISED BULLETIN DATE

Jan. 2003

WIRING INSTRUCTION

58-01-1805

00

0

EXAMPLE:

Component Parts (Small #) Are Included When Ordering The Assembly (Large #).

Cat. No.

FIG. | PART NO. | DESCRIPTION OF PART | NO.REQ. |

1 | Ball Bearing | (1) | |

2 | Ball Bearing | (1) | |

3 | Ball Bearing | (1) | |

4 | Ball Bearing | (1) | |

5 | Needle Bearing | (1) | |

6 | Needle Bearing | (1) | |

7 | (6) | ||

8 | Service Nameplate | (1) | |

9 | Armature | (1) | |

10 | Field | (1) | |

11 | Brush Card Assembly | (1) | |

12 | Pin Housing Assembly | (1) | |

13 | (1) | ||

14 | Switch | (1) | |

15 | Gearcase | (1) | |

16 | Diaphragm | (1) | |

17 | Handle Halve | (1) | |

18 | Motor Housing | (1) | |

19 | Intermediate Gear | (1) | |

20 | Spindle Gear | (1) | |

21 | Retaining Ring | (1) | |

22 | Intermediate Shaft | (1) | |

23 | Spindle | (1) | |

24 | Baffle Assembly | (1) | |

25 | Gasket | (1) | |

26 | Ground Pin | (1) | |

27 | Chuck Screw | (1) | |

29 | Spindle Spacer | (1) | |

30 | Thrust Washer | (1) |

FIG. | PART NO. | DESCRIPTION OF PART | NO.REQ. |

31 | Side Handle Assembly | (1) | |

32 | 1/4 Chuck | (1) | |

33 | Chuck Key | (1) | |

34 | Chuck Key Holder | (1) | |

35 | Fan | (1) | |

36 | Slug | (2) | |

37 | Slug | (1) | |

38 | Brush Spring | (2) | |

39 | Brush Assembly | (2) | |

40 | (1) | ||

41 | Side Handle Clamp | (1) | |

42 | Side Handle | (1) | |

43 | (1) |

LUBRICATION (Type "Y" Grease, No. 49-08-5270)

•Place 5 gm. (.02 oz.) of grease on top of the inserted intermediate ball bearing (1) and on the intermediate pinion (22).

•After inserting all gearing, place 13 gm. (.46 oz.) of grease at the armature pinion location in the gearcase (15) and fill to the top of the intermediate gear (19). Grease must contact at least 25% of the intermediate gear teeth.

Before assembly, lightly coat all press fit areas with lightweight spindle oil.

FIG. NOTES:

4,20 Support the output ball bearing inside the gearcase before pressing off the spindle gear.

5,6 Needle bearings to be pressed flush to .010 under flush from the end which has the vendors identification.

MILWAUKEEELECTRICTOOLCORPORATION

13135 W. LISBON RD., BROOKFIELD, WI 53005

Drwg. 3