TOOL ASSEMBLY

WARNING!

To reduce the risk of injury, always unplug tool before attaching or removing accessories or making adjustments. Use only specifically recommended accessories. Others may be hazardous.

Installing the Side Handle

The side handle may be installed on either side of gear case for right or left handed use. Position side handle in the location which offers best control and guard protection. For operating zones that provide maximum protection for the operator, see "Grinding". To install, thread side handle into side handle socket on desired side of gear case and tighten securely.

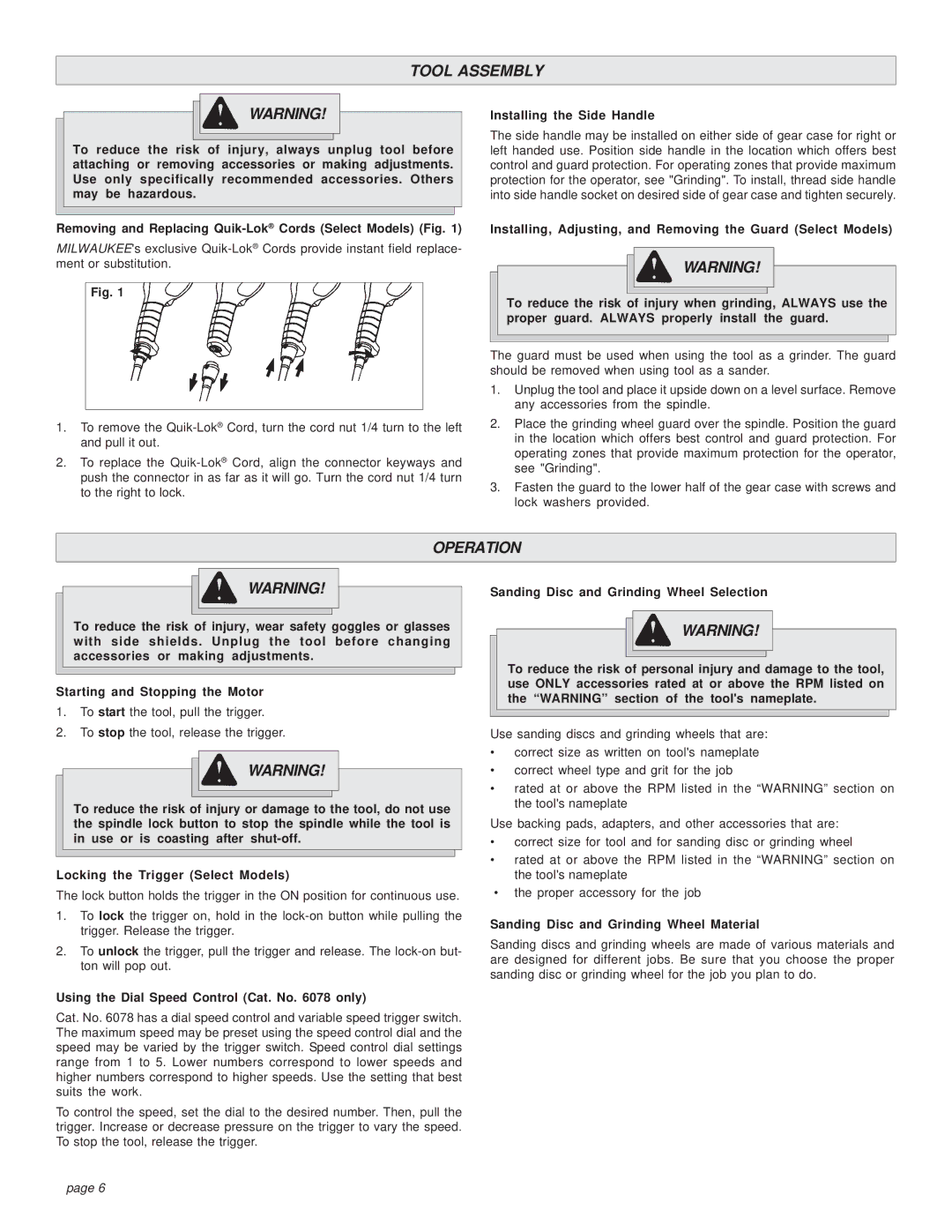

Removing and Replacing Quik-Lok® Cords (Select Models) (Fig. 1)

MILWAUKEE's exclusive

Fig. 1

1.To remove the

2.To replace the

Installing, Adjusting, and Removing the Guard (Select Models)

WARNING!

To reduce the risk of injury when grinding, ALWAYS use the proper guard. ALWAYS properly install the guard.

The guard must be used when using the tool as a grinder. The guard should be removed when using tool as a sander.

1.Unplug the tool and place it upside down on a level surface. Remove any accessories from the spindle.

2.Place the grinding wheel guard over the spindle. Position the guard in the location which offers best control and guard protection. For operating zones that provide maximum protection for the operator, see "Grinding".

3.Fasten the guard to the lower half of the gear case with screws and lock washers provided.

OPERATION

WARNING!

To reduce the risk of injury, wear safety goggles or glasses with side shields. Unplug the tool before changing accessories or making adjustments.

Starting and Stopping the Motor

1.To start the tool, pull the trigger.

Sanding Disc and Grinding Wheel Selection

WARNING!

To reduce the risk of personal injury and damage to the tool, use ONLY accessories rated at or above the RPM listed on the “WARNING” section of the tool's nameplate.

2.To stop the tool, release the trigger.

WARNING!

To reduce the risk of injury or damage to the tool, do not use the spindle lock button to stop the spindle while the tool is in use or is coasting after

Locking the Trigger (Select Models)

The lock button holds the trigger in the ON position for continuous use.

1.To lock the trigger on, hold in the

2.To unlock the trigger, pull the trigger and release. The

Using the Dial Speed Control (Cat. No. 6078 only)

Cat. No. 6078 has a dial speed control and variable speed trigger switch. The maximum speed may be preset using the speed control dial and the speed may be varied by the trigger switch. Speed control dial settings range from 1 to 5. Lower numbers correspond to lower speeds and higher numbers correspond to higher speeds. Use the setting that best suits the work.

To control the speed, set the dial to the desired number. Then, pull the trigger. Increase or decrease pressure on the trigger to vary the speed. To stop the tool, release the trigger.

Use sanding discs and grinding wheels that are:

•correct size as written on tool's nameplate

•correct wheel type and grit for the job

•rated at or above the RPM listed in the “WARNING” section on the tool's nameplate

Use backing pads, adapters, and other accessories that are:

•correct size for tool and for sanding disc or grinding wheel

•rated at or above the RPM listed in the “WARNING” section on the tool's nameplate

•the proper accessory for the job

Sanding Disc and Grinding Wheel Material

Sanding discs and grinding wheels are made of various materials and are designed for different jobs. Be sure that you choose the proper sanding disc or grinding wheel for the job you plan to do.

page 6