Fig. 4 | Plunger | Nut | ||

|

| |||

|

|

| ||

|

|

| Nut |

|

|

|

|

|

|

| Front face of plunger |

| Plunger rod |

|

|

|

|

| |

| Front nut |

|

|

|

|

| Barrel nut |

|

|

| Back nut |

|

|

|

|

|

|

| Carriage frame |

| Plunger rod |

|

|

|

|

|

|

|

|

| Backing |

|

| |

| Washer |

|

| |

|

|

| Spacer |

|

Installing Caulk or Adhesive Tube |

|

| |||

1. Lock trigger or remove battery pack. |

| NOTE: Before using a partially filled | |||

2. Cut nozzle of tube at an angle and |

| tube, remove any hardened material | |||

| with a long nail or piece of wire. | ||||

size per manufacturer's recommenda- |

| ||||

|

| ||||

tion to suit the job. A smaller nozzle | 4. | Press in and hold rod release trigger. | |||

diameter requires more force to push | 5. | Grasp plunger rod handle and pull | |||

the caulk and reduces battery life. | |||||

| plunger rod back to allow the caulk | ||||

|

|

|

| ||

3. Break inner seal of tube using a long |

| tube to fit inside carriage frame. | |||

nail or piece of wire. If the inner seal | 6. | Insert caulk tube into carriage frame. | |||

is not broken, the caulk material may | |||||

7. | Push plunger rod handle forward until | ||||

be forced out the rear end of the tube | |||||

and damage the tool. |

|

| the plunger is against the caulk tube. | ||

|

|

| 8. | Release rod release trigger. | |

|

|

|

|

| |

Fig. 5 | Spacer | Double hub |

|

| |

|

|

|

| ||

| Backing washer | ||||

|

|

|

|

| |

![]() WARNING!

WARNING!

Always lock trigger or remove battery pack before changing or removing accessories. Only use accessories specifically recom- mended for this tool. Others may be hazardous.

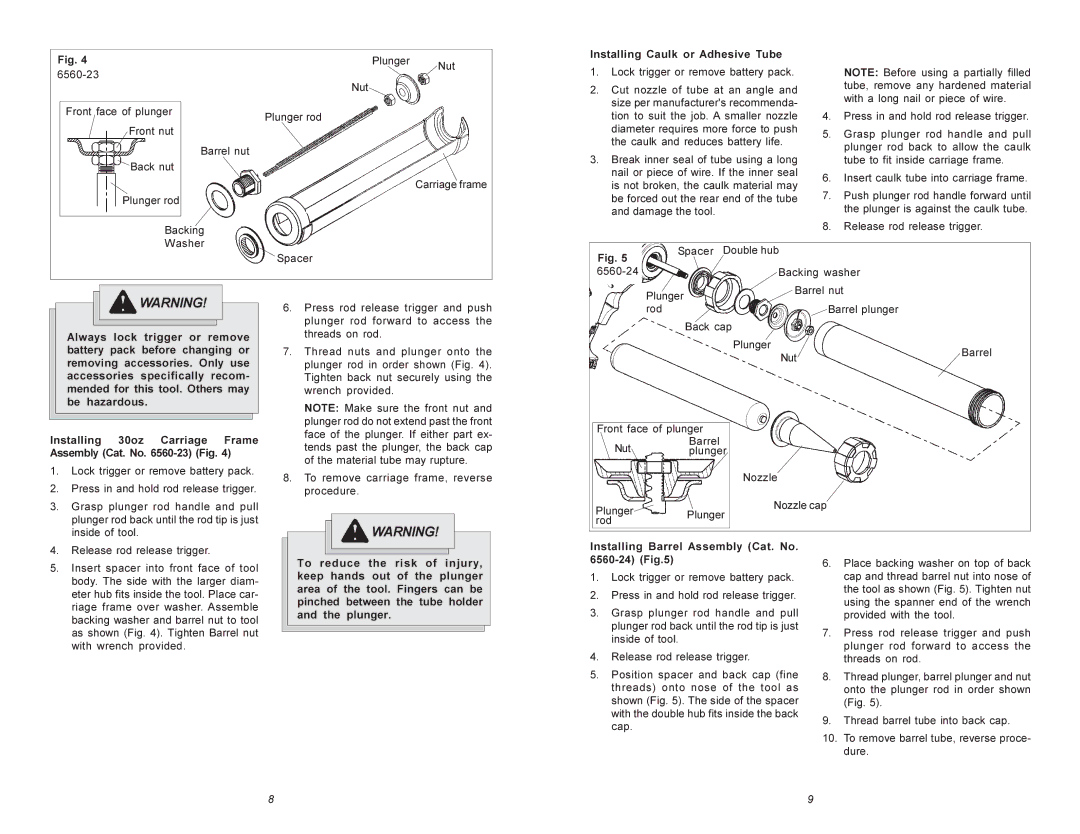

Installing 30oz Carriage Frame Assembly (Cat. No.

1. | Lock trigger or remove battery pack. |

2. | Press in and hold rod release trigger. |

3. | Grasp plunger rod handle and pull |

| plunger rod back until the rod tip is just |

| inside of tool. |

6.Press rod release trigger and push plunger rod forward to access the threads on rod.

7.Thread nuts and plunger onto the plunger rod in order shown (Fig. 4). Tighten back nut securely using the wrench provided.

NOTE: Make sure the front nut and plunger rod do not extend past the front face of the plunger. If either part ex- tends past the plunger, the back cap of the material tube may rupture.

8.To remove carriage frame, reverse procedure.

WARNING!

Plunger |

| Barrel nut |

|

|

|

| |

rod |

| Barrel plunger |

|

| Back cap |

|

|

| Plunger |

| Barrel |

|

| Nut | |

|

|

|

Front face of plunger |

| |

Nut | Barrel |

|

plunger |

| |

|

| Nozzle |

Plunger | Plunger | Nozzle cap |

| ||

rod |

| |

|

| |

4. | Release rod release trigger. |

5. | Insert spacer into front face of tool |

| body. The side with the larger diam- |

| eter hub fits inside the tool. Place car- |

| riage frame over washer. Assemble |

| backing washer and barrel nut to tool |

| as shown (Fig. 4). Tighten Barrel nut |

| with wrench provided. |

To reduce the risk of injury, keep hands out of the plunger area of the tool. Fingers can be pinched between the tube holder and the plunger.

Installing Barrel Assembly (Cat. No.

1.Lock trigger or remove battery pack.

2.Press in and hold rod release trigger.

3.Grasp plunger rod handle and pull plunger rod back until the rod tip is just inside of tool.

4.Release rod release trigger.

5.Position spacer and back cap (fine threads) onto nose of the tool as shown (Fig. 5). The side of the spacer with the double hub fits inside the back cap.

6.Place backing washer on top of back cap and thread barrel nut into nose of the tool as shown (Fig. 5). Tighten nut using the spanner end of the wrench provided with the tool.

7.Press rod release trigger and push plunger rod forward to access the threads on rod.

8.Thread plunger, barrel plunger and nut onto the plunger rod in order shown (Fig. 5).

9.Thread barrel tube into back cap.

10.To remove barrel tube, reverse proce- dure.

8 | 9 |