Installing Sausage Type Pack

Always check sausage packs for punc- tures or damage to the pack before install- ing. Do not use a damaged or frozen pack.

1.Lock trigger or remove battery pack.

2.Press in and hold rod release trigger.

3.Grasp plunger rod handle and pull plunger rod back to allow sausage pack to fit inside barrel tube.

4.Insert pack into barrel tube.

5.Cut off end of sausage pack.

NOTE: Before using a partially filled pack, remove any hardened material.

6.Insert nozzle supplied with the sau- sage pack into the nozzle cap (coarse thread). Thread nozzle cap onto the front of barrel tube.

7.Cut nozzle at an angle and size per manufacturer's recommendation to suit the job. A smaller nozzle diameter re- quires more force to push the caulk and reduces battery life.

8.Press in and hold rod release trigger.

9.Push plunger rod handle forward until plunger is against sausage pack.

10.Release rod release trigger.

OPERATION

![]() WARNING!

WARNING!

When tool is not in use, lock trig- ger to prevent the tool from be- ing accidentally turned on.

Starting and Stopping and Controlling Speed

1.Pull trigger to dispense caulk.

2.Increase or decrease pressure on trig- ger to adjust the speed for proper bead width and material feed rate. Material type, temperature and nozzle diameter will all affect flow rate. When using a tube or pack with a smaller nozzle di- ameter use a slower speed or the material may be forced around the rear tube seat.

3.Release trigger to stop dispensing caulk.

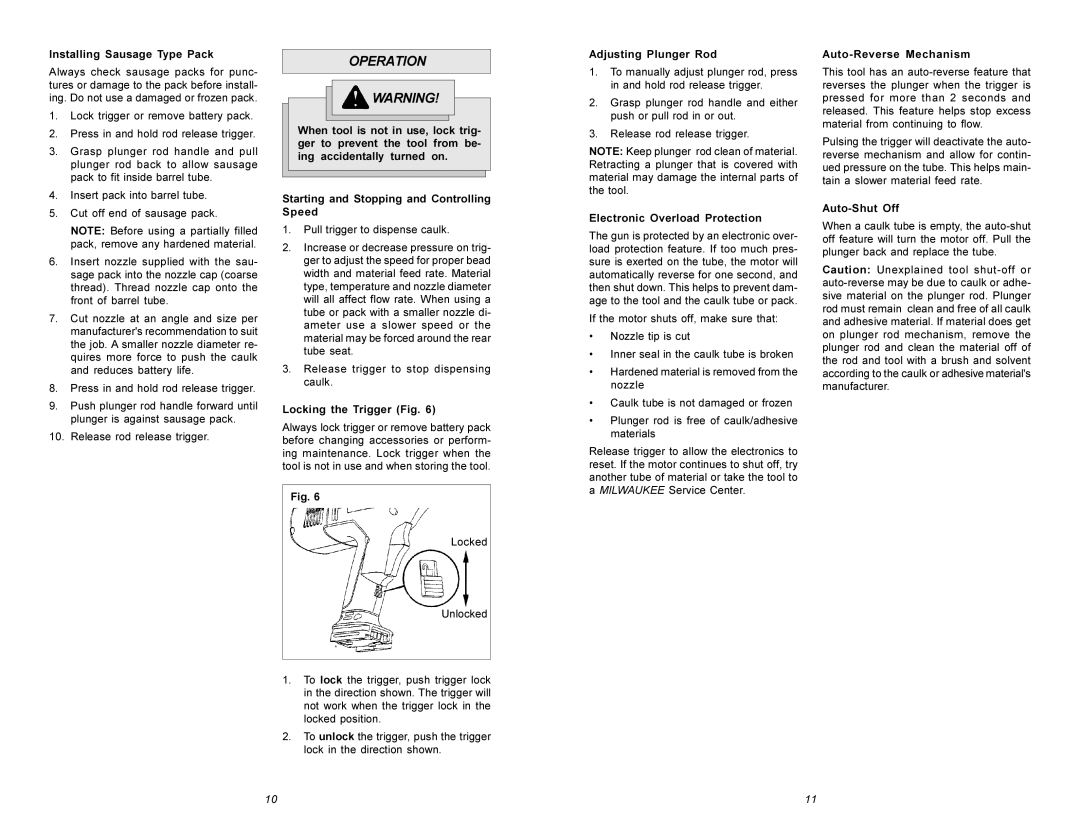

Locking the Trigger (Fig. 6)

Always lock trigger or remove battery pack before changing accessories or perform- ing maintenance. Lock trigger when the tool is not in use and when storing the tool.

Fig. 6

Locked

Unlocked

Adjusting Plunger Rod

1.To manually adjust plunger rod, press in and hold rod release trigger.

2.Grasp plunger rod handle and either push or pull rod in or out.

3.Release rod release trigger.

NOTE: Keep plunger rod clean of material. Retracting a plunger that is covered with material may damage the internal parts of the tool.

Electronic Overload Protection

The gun is protected by an electronic over- load protection feature. If too much pres- sure is exerted on the tube, the motor will automatically reverse for one second, and then shut down. This helps to prevent dam- age to the tool and the caulk tube or pack.

If the motor shuts off, make sure that:

•Nozzle tip is cut

•Inner seal in the caulk tube is broken

•Hardened material is removed from the nozzle

•Caulk tube is not damaged or frozen

•Plunger rod is free of caulk/adhesive materials

Release trigger to allow the electronics to reset. If the motor continues to shut off, try another tube of material or take the tool to a MILWAUKEE Service Center.

Auto-Reverse Mechanism

This tool has an

Pulsing the trigger will deactivate the auto- reverse mechanism and allow for contin- ued pressure on the tube. This helps main- tain a slower material feed rate.

Auto-Shut Off

When a caulk tube is empty, the

Caution: Unexplained tool

1.To lock the trigger, push trigger lock in the direction shown. The trigger will not work when the trigger lock in the locked position.

2.To unlock the trigger, push the trigger lock in the direction shown.

10 | 11 |