The electronic control system regulates the temperature within the tool’s heating element. Unlike

Cat. No. 8978 is a variable temperature heat gun with a range between 200° F and 1100° F (93° C to 593° C). The heat adjustment knob is a dial with numbers 1 through 6 on it as shown. The lower numbers corre- spond to cooler temperatures and higher numbers correspond to warmer temperatures. To adjust temperature, simply turn the dial to the left or the right.

Cat. No. 8986-20 and 8988-20 (Fig. 4)

These heat guns have a variable temperature control switch, which allows the user to adjust the temperature for specific applications.

Fig. 4

Temperature display

Temperature control switch

The electronic temperature control system regulates the temperature within the tool's heating element. Unlike

On Cat. No.

1.Slide the airflow control switch (blue switch) to Position II or III to operate the temperature control switch.

2.To adjust the temperature, slide the temperature control switch (red switch) to the desired position.

When the temperature control switch is set to the desired position on the

Airflow/Temperature Settings (8986-20 & 8988-20)

Airflow |

|

|

| Air Flow at |

Control | Airflow | Minimum | Maximum | Maximum |

Switch | Fan | Temperature | Temperature | Temperature |

Setting | Speed | Setting | Setting | Setting |

|

|

|

|

|

Position I | High | 90°F | 90°F | 7 CFM* |

Position II | L o w | 90°F | 1100°F | 8.8 CFM |

Position III | High | 90°F | 1100°F | 16 CFM |

|

|

|

|

|

|

|

| * Cubic feet per minute | |

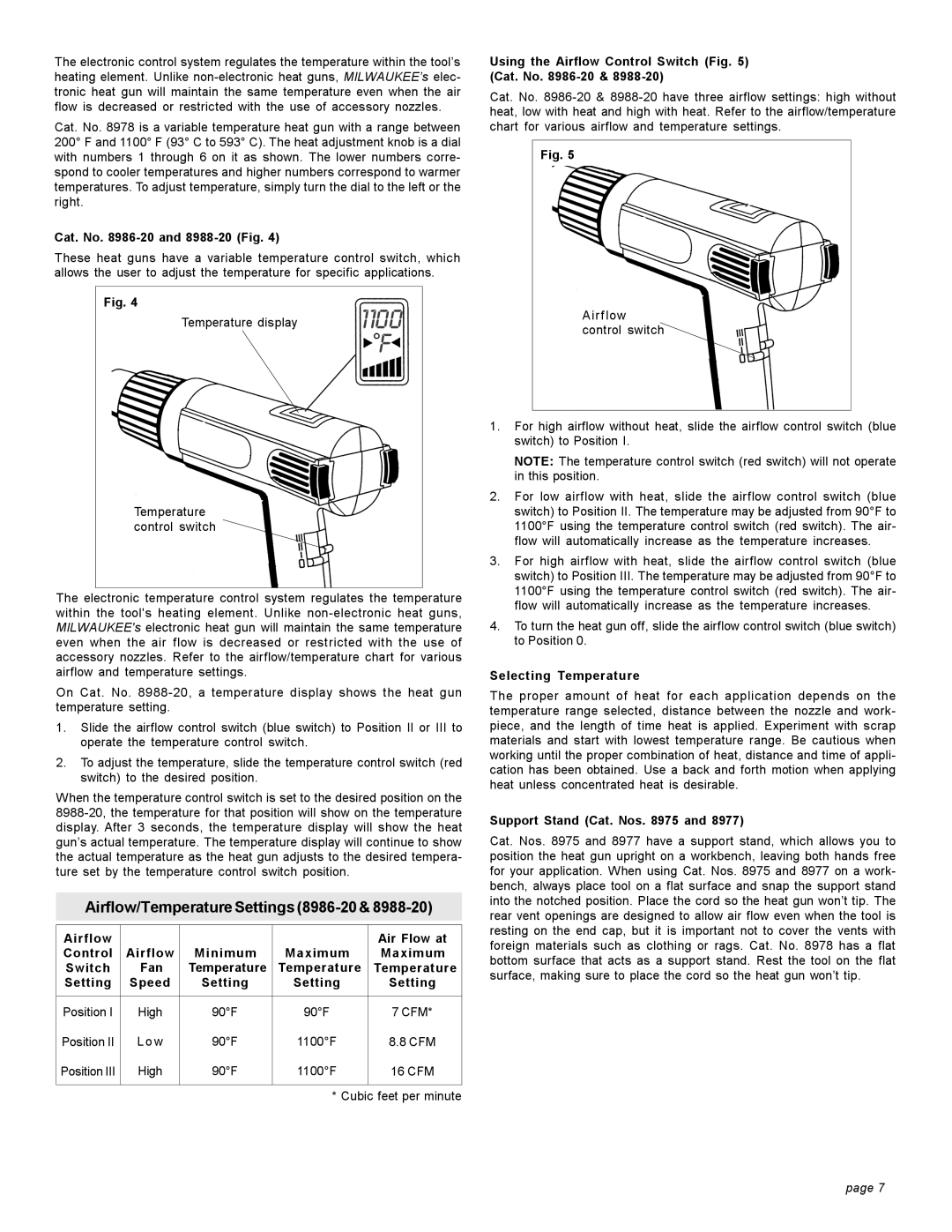

Using the Airflow Control Switch (Fig. 5)

(Cat. No.

Cat. No.

Fig. 5

Airflow control switch

1.For high airflow without heat, slide the airflow control switch (blue switch) to Position I.

NOTE: The temperature control switch (red switch) will not operate in this position.

2.For low airflow with heat, slide the airflow control switch (blue switch) to Position II. The temperature may be adjusted from 90°F to 1100°F using the temperature control switch (red switch). The air- flow will automatically increase as the temperature increases.

3.For high airflow with heat, slide the airflow control switch (blue switch) to Position III. The temperature may be adjusted from 90°F to 1100°F using the temperature control switch (red switch). The air- flow will automatically increase as the temperature increases.

4.To turn the heat gun off, slide the airflow control switch (blue switch) to Position 0.

Selecting Temperature

The proper amount of heat for each application depends on the temperature range selected, distance between the nozzle and work- piece, and the length of time heat is applied. Experiment with scrap materials and start with lowest temperature range. Be cautious when working until the proper combination of heat, distance and time of appli- cation has been obtained. Use a back and forth motion when applying heat unless concentrated heat is desirable.

Support Stand (Cat. Nos. 8975 and 8977)

Cat. Nos. 8975 and 8977 have a support stand, which allows you to position the heat gun upright on a workbench, leaving both hands free for your application. When using Cat. Nos. 8975 and 8977 on a work- bench, always place tool on a flat surface and snap the support stand into the notched position. Place the cord so the heat gun won’t tip. The rear vent openings are designed to allow air flow even when the tool is resting on the end cap, but it is important not to cover the vents with foreign materials such as clothing or rags. Cat. No. 8978 has a flat bottom surface that acts as a support stand. Rest the tool on the flat surface, making sure to place the cord so the heat gun won’t tip.

page 7