Driving Screws and Nut Running

Drill a pilot hole when driving screws into thick or hard materials. Set the torque se- lector collar to the proper position and set the speed to low. Use the proper style and size screwdriver bit for the type of screw you are using.

With the screwdriver bit in the screw, place the tip of the screw on the workpiece and apply firm pressure before pulling the trig- ger. Screws can be removed by reversing the motor.

Overloading

Continuous overloading may cause per- manent damage to tool or battery pack.

WARNING!

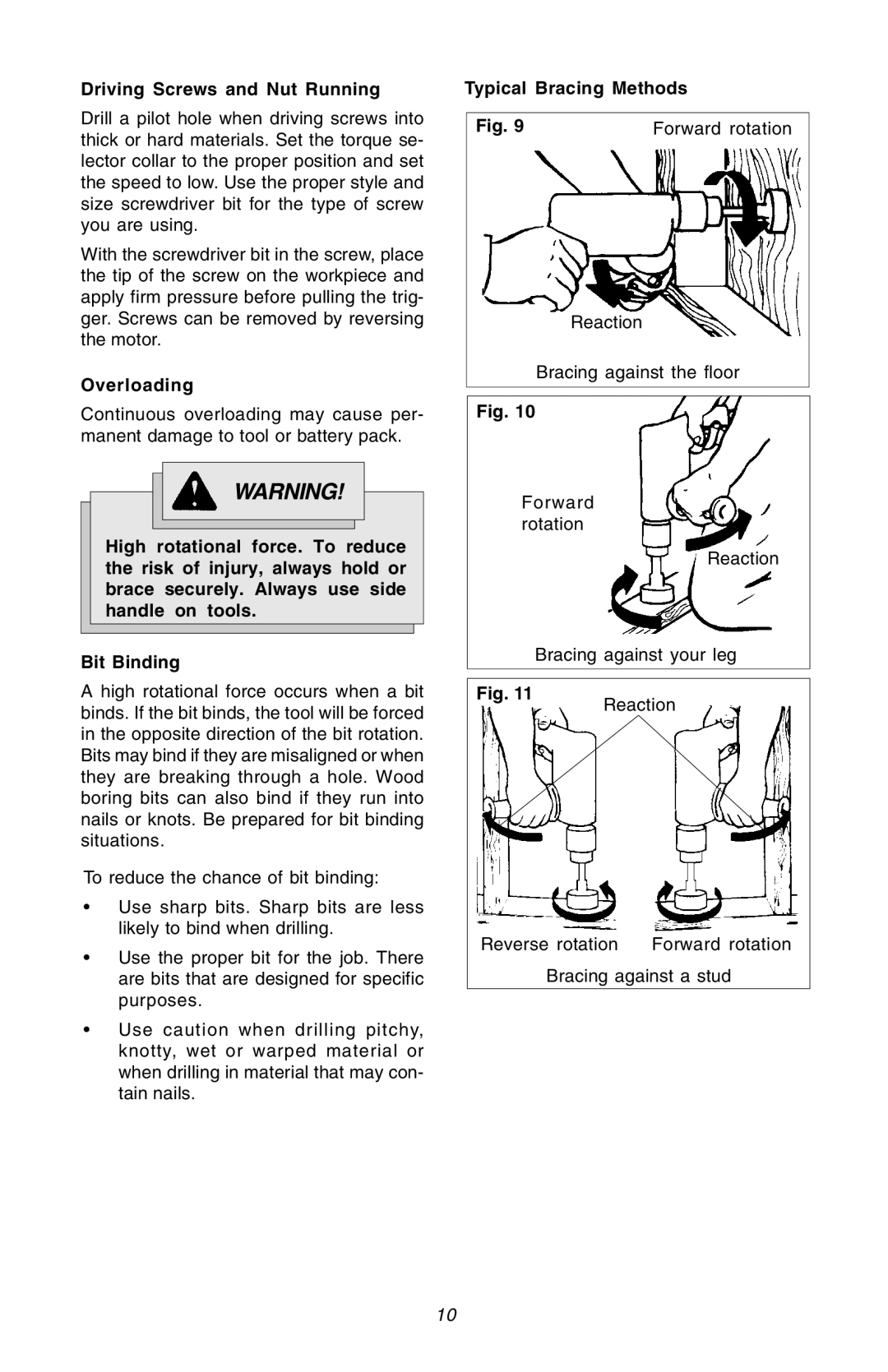

High rotational force. To reduce the risk of injury, always hold or brace securely. Always use side handle on tools.

Bit Binding

A high rotational force occurs when a bit binds. If the bit binds, the tool will be forced in the opposite direction of the bit rotation. Bits may bind if they are misaligned or when they are breaking through a hole. Wood boring bits can also bind if they run into nails or knots. Be prepared for bit binding situations.

To reduce the chance of bit binding:

•Use sharp bits. Sharp bits are less likely to bind when drilling.

•Use the proper bit for the job. There are bits that are designed for specific purposes.

•Use caution when drilling pitchy, knotty, wet or warped material or when drilling in material that may con- tain nails.

Typical Bracing Methods

Fig. 9 | Forward rotation |

Reaction

Bracing against the floor

Fig. 10

Forward rotation

Reaction

Bracing against your leg

Fig. 11 | Reaction | |

| ||

Reverse rotation | Forward rotation | |

| Bracing against a stud | |

10