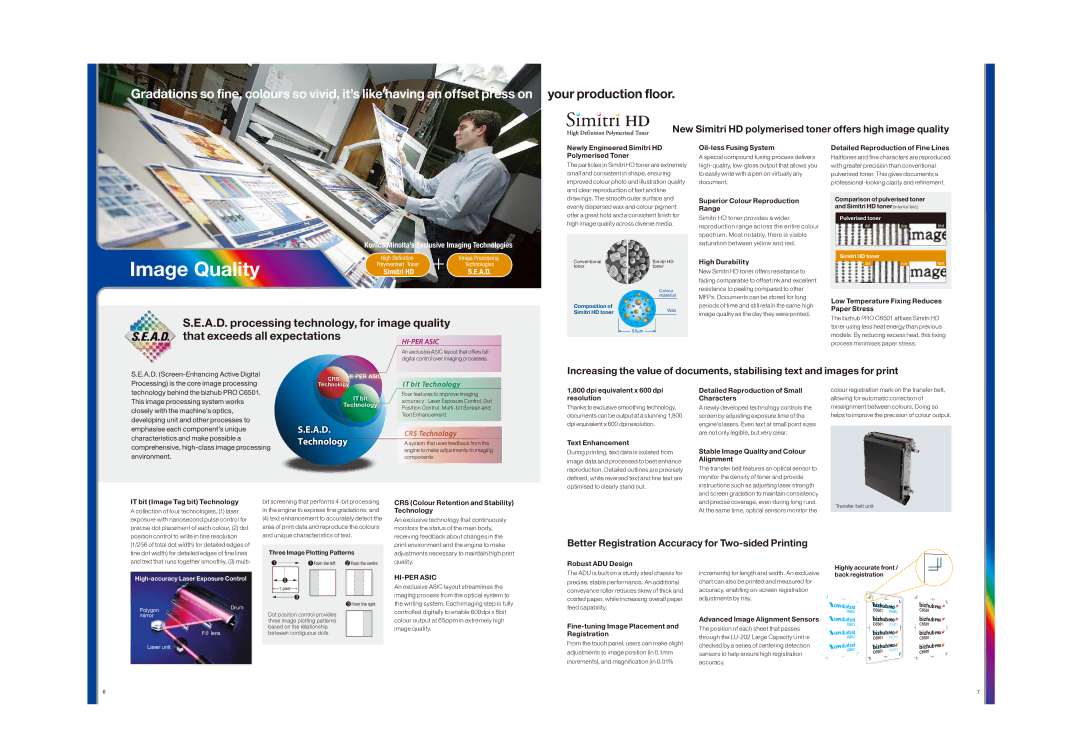

An exclusive ASIC layout that offers full digital control over imaging processes.

IT bit Technology

Four features to improve imaging accuracy: Laser Exposure Control, Dot Position Control, Multi-bit Screen and Text Enhancement.

CRS Technology

A system that uses feedback from the engine to make adjustments to imaging components.

CRS (Colour Retention and Stability) Technology

An exclusive technology that continuously monitors the status of the main body, receiving feedback about changes in the print environment and the engine to make adjustments necessary to maintain high print quality.

HI-PER ASIC

An exclusive ASIC layout streamlines the imaging process from the optical system to the writing system. Each imaging step is fully controlled digitally to enable 600dpi x 8bit colour output at 65ppm in extremely high image quality.

HI-PER ASIC

Gradations so fine, colours so vivid, it’s like having an offset press on your production floor.

New Simitri HD polymerised toner offers high image quality

Konica Minolta’s Exclusive Imaging Technologies

Image Quality | High Definition | Image Processing |

Simitri HD | S.E.A.D. |

| Polymerised Toner | Technologies |

S.E.A.D. processing technology, for image quality that exceeds all expectations

Newly Engineered Simitri HD Polymerised Toner

The particles in Simitri HD toner are extremely small and consistent in shape, ensuring improved colour photo and illustration quality and clear reproduction of text and line drawings. The smooth outer surface and evenly dispersed wax and colour pigment offer a great hold and a consistent finish for high image quality across diverse media.

Conventional | | Simitri HD |

toner | | toner |

| | | | | Colour |

| | | | | material |

Composition of | | | Wax |

Simitri HD toner | | |

| | | | | |

| | | | | |

| | | | | |

Oil-less Fusing System

A special compound fusing process delivers high-quality, low-gloss output that allows you to easily write with a pen on virtually any document.

Superior Colour Reproduction Range

Simitri HD toner provides a wider reproduction range across the entire colour spectrum. Most notably, there is visible saturation between yellow and red.

High Durability

New Simitri HD toner offers resistance to fading comparable to offset ink and excellent resistance to peeling compared to other MFPs. Documents can be stored for long periods of time and still retain the same high image quality as the day they were printed.

Detailed Reproduction of Fine Lines

Halftones and fine characters are reproduced with greater precision than conventional pulverised toner. This gives documents a professional-looking clarity and refinement.

Comparison of pulverised toner and Simitri HD toner (internal test)

Pulverised toner

Simitri HD toner

Low Temperature Fixing Reduces Paper Stress

The bizhub PRO C6501 affixes Simitri HD toner using less heat energy than previous models. By reducing excess heat, this fixing process minimises paper stress.

S.E.A.D. (Screen-Enhancing Active Digital Processing) is the core image processing

CRS | HI-PER ASIC |

|

Technology |

Increasing the value of documents, stabilising text and images for print

technology behind the bizhub PRO C6501. This image processing system works closely with the machine’s optics, developing unit and other processes to emphasise each component’s unique characteristics and make possible a comprehensive, high-class image processing environment.

1,800 dpi equivalent x 600 dpi resolution

Thanks to exclusive smoothing technology, documents can be output at a stunning 1,800 dpi equivalent x 600 dpi resolution.

Text Enhancement

During printing, text data is isolated from image data and processed to best enhance reproduction. Detailed outlines are precisely defined, while reversed text and fine text are optimised to clearly stand out.

Detailed Reproduction of Small Characters

A newly developed technology controls the screen by adjusting exposure time of the engine’s lasers. Even text at small point sizes are not only legible, but very clear.

Stable Image Quality and Colour Alignment

The transfer belt features an optical sensor to monitor the density of toner and provide instructions such as adjusting laser strength and screen gradation to maintain consistency

colour registration mark on the transfer belt, allowing for automatic correction of misalignment between colours. Doing so helps to improve the precision of colour output.

IT bit (Image Tag bit) Technology

A collection of four technologies, (1) laser

bit screening that performs 4-bit processing in the engine to express fine gradations, and

and precise coverage, even during long runs. At the same time, optical sensors monitor the

exposure with nanosecond pulse control for precise dot placement of each colour, (2) dot position control to write in fine resolution (1/256 of total dot width) for detailed edges of fine dot width) for detailed edges of fine lines and text that runs together smoothly, (3) multi-

High-accuracy Laser Exposure Control

Polygon | Drum |

|

mirror | |

| Fθlens |

Laser unit | |

(4)text enhancement to accurately detect the area of print data and reproduce the colours and unique characteristics of text.

Three Image Plotting Patterns

1 | | 1 From the left | 2 From the centre |

|

2

1 pixel

1 pixel

3

3 From the right

Dot position control provides three image plotting patterns based on the relationship between contiguous dots.

Better Registration Accuracy for Two-sided Printing

Robust ADU Design

The ADU is built on a sturdy steel chassis for | increments) for length and width. An exclusive |

precise, stable performance. An additional | chart can also be printed and measured for |

conveyance roller reduces skew of thick and | accuracy, enabling on-screen registration |

coated paper, while increasing overall paper | adjustments by tray. |

feed capability. | |

Advanced Image Alignment Sensors

| Fine-tuning Image Placement and | The position of each sheet that passes |

| Registration |

| through the LU-202 Large Capacity Unit is |

| From the touch panel, users can make slight |

| checked by a series of centering detection |

| adjustments to image position (in 0.1mm |

| sensors to help ensure high registration |

| increments), and magnification (in 0.01% | accuracy. |

Highly accurate front / back registration