5

Maintaining

Your Log

Splitter

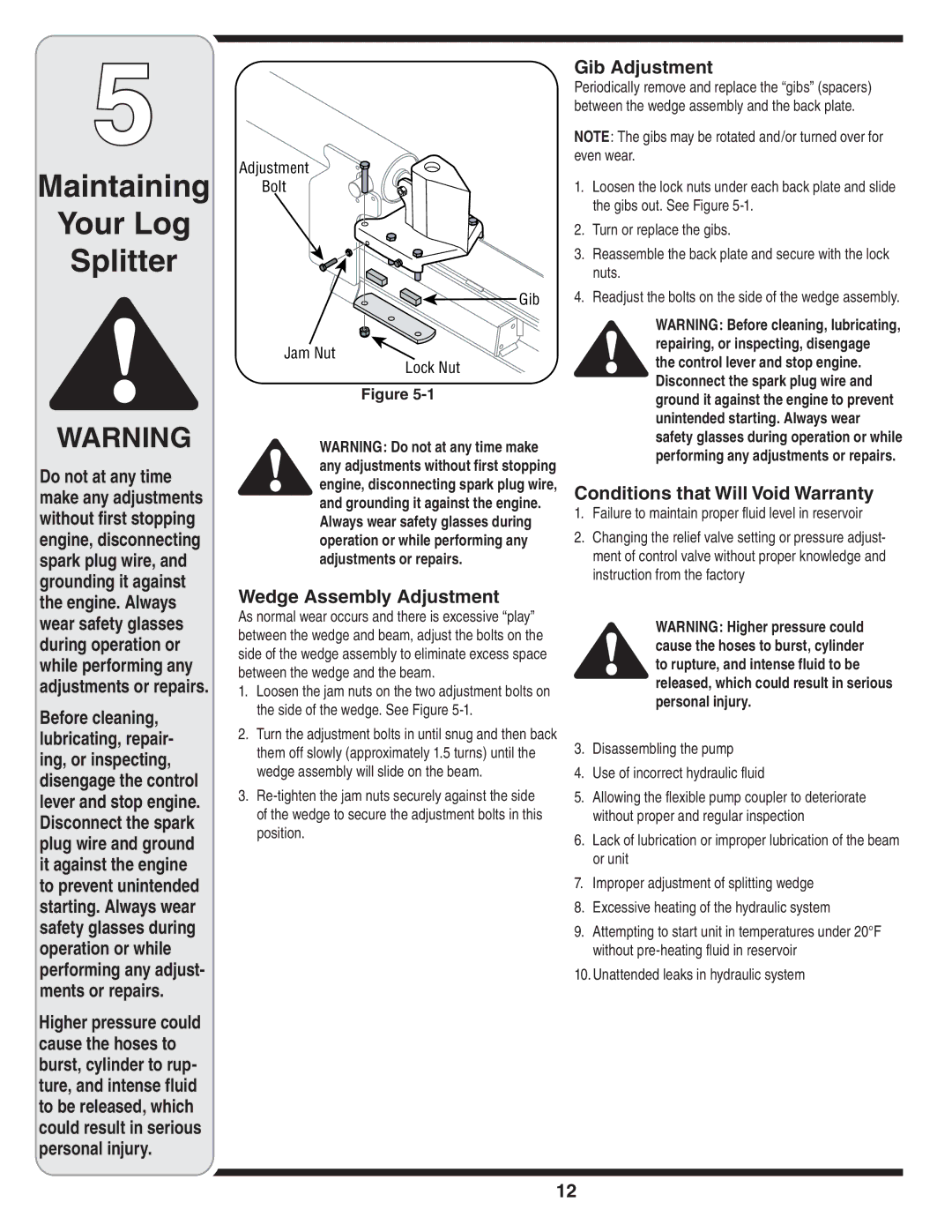

Adjustment

Bolt

Jam Nut

Gib

Lock Nut

Gib Adjustment

Periodically remove and replace the “gibs” (spacers) between the wedge assembly and the back plate.

NOTE: The gibs may be rotated and/or turned over for even wear.

1.Loosen the lock nuts under each back plate and slide the gibs out. See Figure

2.Turn or replace the gibs.

3.Reassemble the back plate and secure with the lock nuts.

4.Readjust the bolts on the side of the wedge assembly.

WARNING: Before cleaning, lubricating, repairing, or inspecting, disengage the control lever and stop engine. Disconnect the spark plug wire and

WARNING

Do not at any time make any adjustments without first stopping engine, disconnecting spark plug wire, and grounding it against the engine. Always wear safety glasses during operation or while performing any adjustments or repairs.

Before cleaning, lubricating, repair- ing, or inspecting, disengage the control lever and stop engine. Disconnect the spark plug wire and ground it against the engine to prevent unintended starting. Always wear safety glasses during operation or while performing any adjust- ments or repairs.

Higher pressure could cause the hoses to burst, cylinder to rup- ture, and intense fluid to be released, which could result in serious personal injury.

Figure

WARNING: Do not at any time make any adjustments without first stopping engine, disconnecting spark plug wire, and grounding it against the engine. Always wear safety glasses during operation or while performing any adjustments or repairs.

Wedge Assembly Adjustment

As normal wear occurs and there is excessive “play” between the wedge and beam, adjust the bolts on the side of the wedge assembly to eliminate excess space between the wedge and the beam.

1.Loosen the jam nuts on the two adjustment bolts on the side of the wedge. See Figure

2.Turn the adjustment bolts in until snug and then back them off slowly (approximately 1.5 turns) until the wedge assembly will slide on the beam.

3.

ground it against the engine to prevent unintended starting. Always wear safety glasses during operation or while performing any adjustments or repairs.

Conditions that Will Void Warranty

1.Failure to maintain proper fluid level in reservoir

2.Changing the relief valve setting or pressure adjust- ment of control valve without proper knowledge and instruction from the factory

WARNING: Higher pressure could cause the hoses to burst, cylinder to rupture, and intense fluid to be released, which could result in serious personal injury.

3.Disassembling the pump

4.Use of incorrect hydraulic fluid

5.Allowing the flexible pump coupler to deteriorate without proper and regular inspection

6.Lack of lubrication or improper lubrication of the beam or unit

7.Improper adjustment of splitting wedge

8.Excessive heating of the hydraulic system

9.Attempting to start unit in temperatures under 20°F without

10.Unattended leaks in hydraulic system

12