•Remove the hex bolt from the center of the engine pulley (or the electric PTO clutch on units so equipped) and gently lower it off of the engine crankshaft. Be careful not to lose any washers or spacers which may be found on top of the engine pulley or the electric PTO clutch. See Figure 18.

•On units equipped with an electric PTO, the engine pulley is located directly above the electric PTO clutch. Lower the engine pulley far enough to be able to remove the upper drive belt from around it.

IMPORTANT: When remounting the engine pulley or electric PTO clutch, torque the center hex bolt to between 38

•Remove the drive belt by feeding it from both ends toward the front idler pulley on the

•Reassemble by following the above steps in reverse order.

•Reroute the new belt around the pulleys, belt keepers and keeper pins EXACTLY as the old one was routed. Refer to Figure 16.

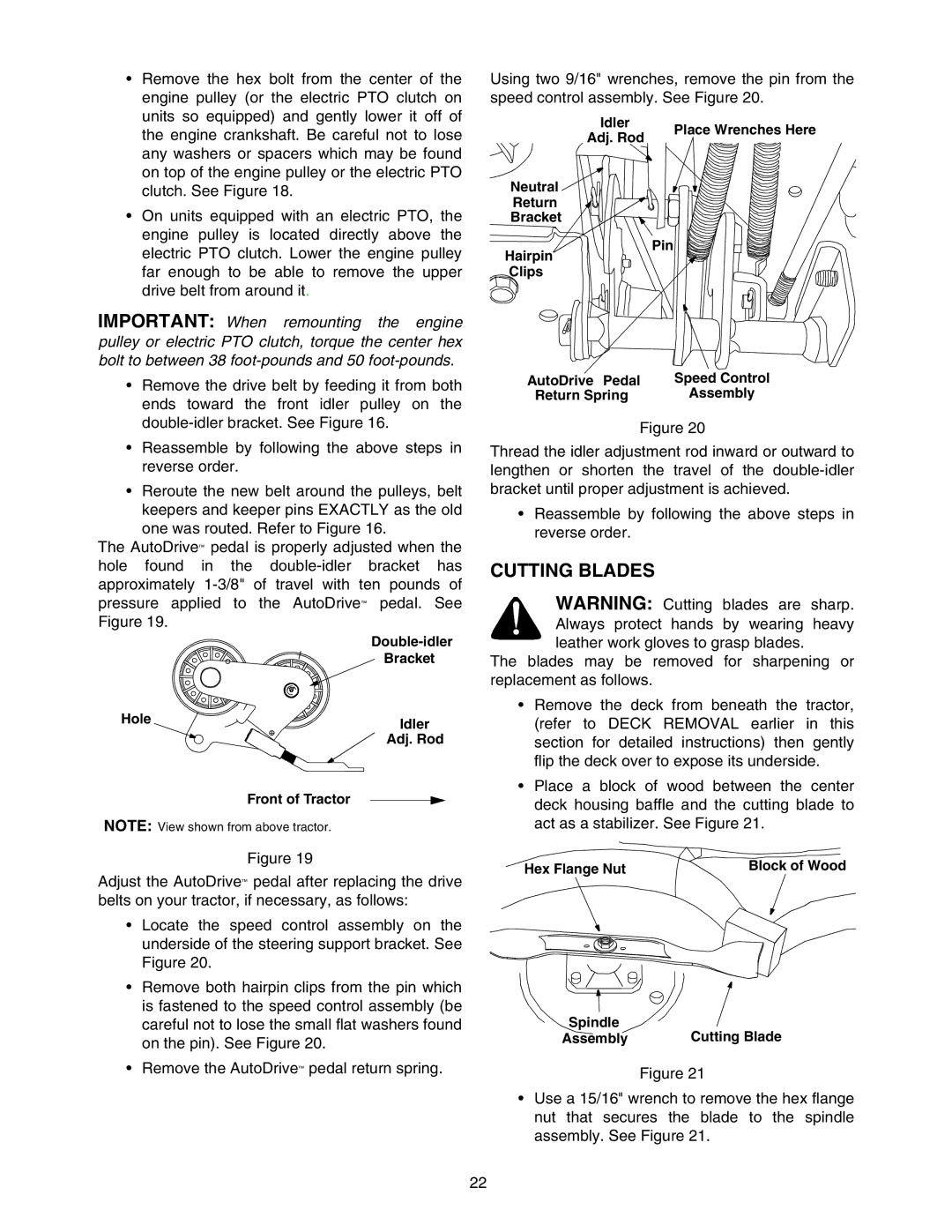

The AutoDrive™ pedal is properly adjusted when the hole found in the

|

|

|

|

|

|

|

|

|

|

| Bracket |

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

Hole |

|

|

|

|

| Idler | |||||

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| Adj. Rod |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Front of Tractor

NOTE: View shown from above tractor.

Figure 19

Adjust the AutoDrive™ pedal after replacing the drive belts on your tractor, if necessary, as follows:

•Locate the speed control assembly on the underside of the steering support bracket. See Figure 20.

•Remove both hairpin clips from the pin which is fastened to the speed control assembly (be careful not to lose the small flat washers found on the pin). See Figure 20.

•Remove the AutoDrive™ pedal return spring.

Using two 9/16" wrenches, remove the pin from the speed control assembly. See Figure 20.

Idler | Place Wrenches Here | |

Adj. Rod | ||

|

Neutral ![]()

![]()

![]()

Return

Bracket

Pin

Hairpin

Clips

AutoDrive™ Pedal | Speed Control |

Return Spring | Assembly |

Figure 20

Thread the idler adjustment rod inward or outward to lengthen or shorten the travel of the

•Reassemble by following the above steps in reverse order.

CUTTING BLADES

WARNING: Cutting blades are sharp. Always protect hands by wearing heavy leather work gloves to grasp blades.

The blades may be removed for sharpening or replacement as follows.

•Remove the deck from beneath the tractor, (refer to DECK REMOVAL earlier in this section for detailed instructions) then gently flip the deck over to expose its underside.

•Place a block of wood between the center deck housing baffle and the cutting blade to act as a stabilizer. See Figure 21.

Hex Flange Nut | Block of Wood |

Spindle | Cutting Blade |

Assembly |

Figure 21

•Use a 15/16" wrench to remove the hex flange nut that secures the blade to the spindle assembly. See Figure 21.

22