wheel hub.This position gives power drive to the left wheel only, making the unit easier to maneuver.

Both Wheels Driving

•Rotate wheel assembly to align hole in the hub with the inner hole on the axle shaft. Insert klick pin in the hole. Outer axle shaft hole should be visible.

IMPORTANT: NEVER operate the snow thrower with the click pin inserted through both the RIM and the OUTSIDE HOLE in the axle. Doing so can result in serious damage to the drive system.

Inside Hole |

In Axle |

Click Pin In |

Outside Hole |

Figure 12

SECTION 6: MAINTAINING YOUR SNOW THROWER

WARNING: Before lubricating, repairing, or inspecting, disengage all clutch levers and stop engine. Wait until all moving parts have come to a complete stop. Disconnect spark plug wire and ground it against the engine to prevent unintended starting.

Gear Shaft

Lubricate the gear shaft with

Refer to Figure 9.

IMPORTANT: Keep all grease and oil off of the rubber friction wheel and aluminum drive plate.

Lubrication

Engine

Refer to the separate engine manual packed with your unit for all engine lubrication instructions.

WARNING: If any adjustments need to be made to the engine while the engine is running (e.g. carburetor), keep clear of all moving parts. Be careful of muffler, engine and other surrounding heated surfaces.

Wheels

•Oil or spray lubricant into bearings at wheels at least once a season. Pull klick pin, remove wheels, clean and coat axles with a multipurpose automotive grease. See Figure 13.

Klick Pin |

Axle |

Figure 13

Chute Directional Control

•The worm gear on the chute directional control should be greased with multipurpose automotive grease.

Gear Case

The gear case is lubricated with grease at the factory and it does not require checking. If disassembled for any reason, lubricate with 2 ounces of Shell Alvania grease EPR00, part number

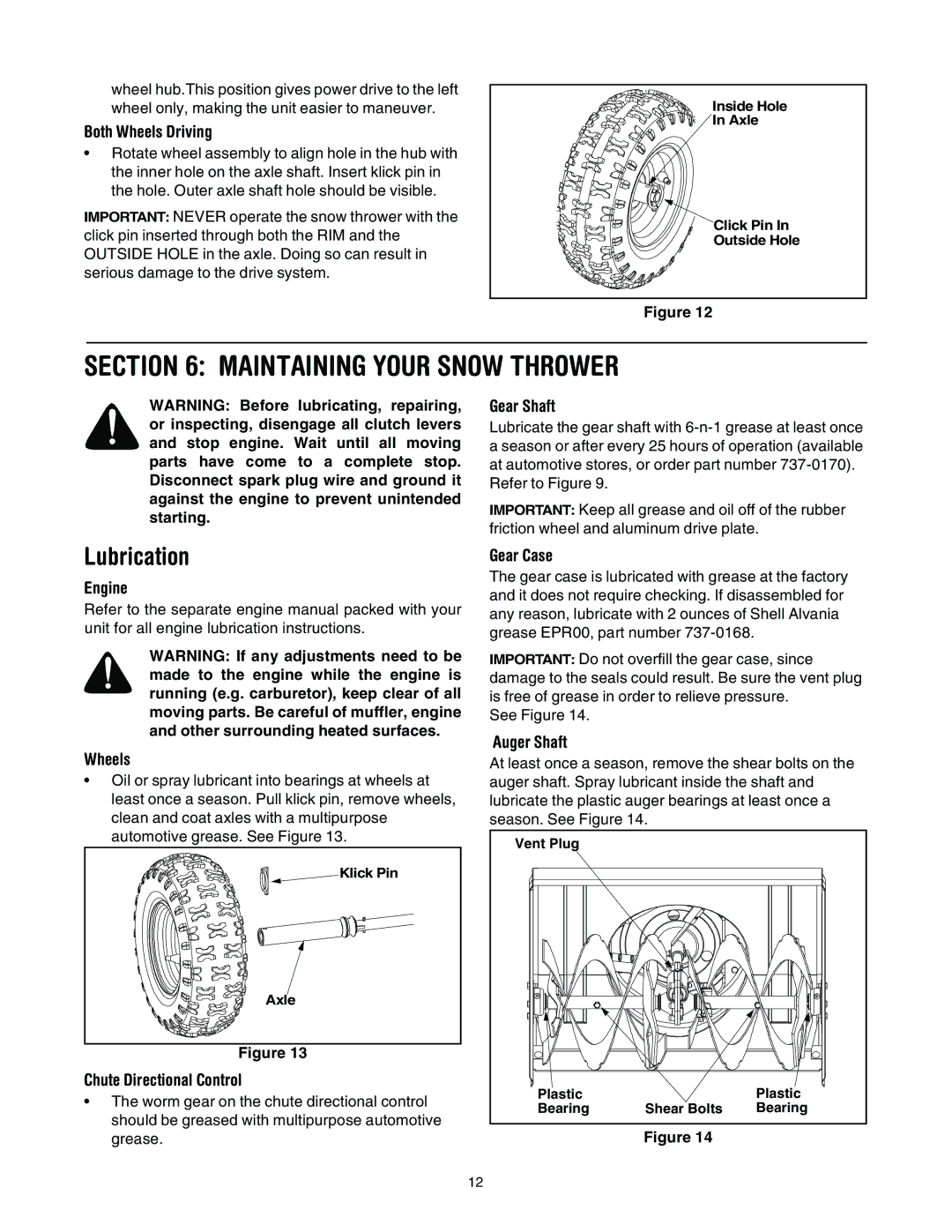

IMPORTANT: Do not overfill the gear case, since damage to the seals could result. Be sure the vent plug is free of grease in order to relieve pressure.

See Figure 14.

Auger Shaft

At least once a season, remove the shear bolts on the auger shaft. Spray lubricant inside the shaft and lubricate the plastic auger bearings at least once a season. See Figure 14.

Vent Plug |

|

|

Plastic |

| Plastic |

Bearing | Shear Bolts | Bearing |

Figure 14

12