Chute

Assembly

Hex Head

Screw

Chute | Hex Lock | |

Flange | ||

Nut | ||

Keeper | ||

| Figure 7 | |

| Lock Washer | |

| Hex Nut | |

Hex Bolt |

|

Upper

Chute

Crank

Bracket

Figure 8

Carriage Bolts

Hex Lock Nuts

Figure 9

Flat Chute

Washers Crank

Hairpin Clip

Lower

Chute Crank Plastic

Bracket Bushing

Figure 10

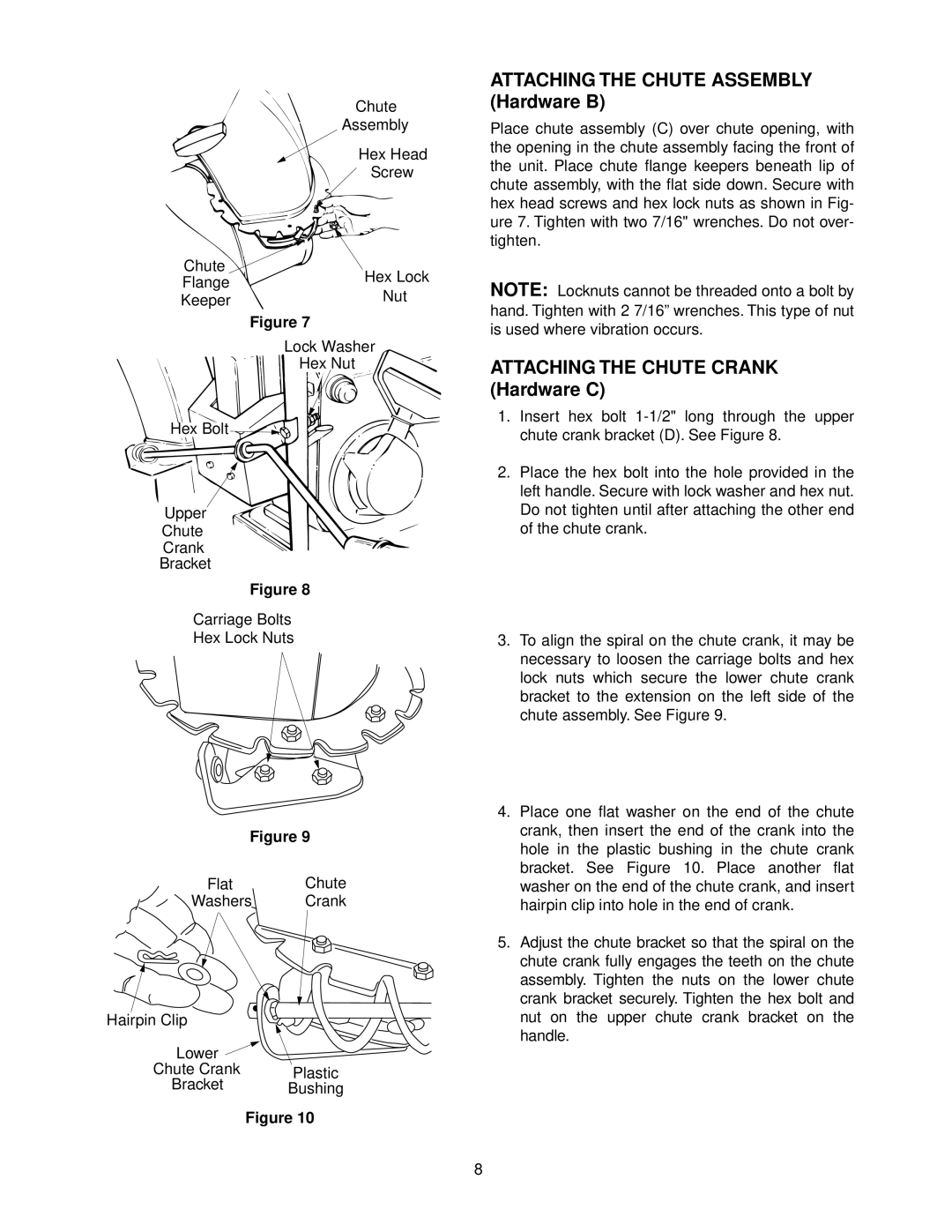

ATTACHING THE CHUTE ASSEMBLY (Hardware B)

Place chute assembly (C) over chute opening, with the opening in the chute assembly facing the front of the unit. Place chute flange keepers beneath lip of chute assembly, with the flat side down. Secure with hex head screws and hex lock nuts as shown in Fig- ure 7. Tighten with two 7/16" wrenches. Do not over- tighten.

NOTE: Locknuts cannot be threaded onto a bolt by hand. Tighten with 2 7/16” wrenches. This type of nut is used where vibration occurs.

ATTACHING THE CHUTE CRANK (Hardware C)

1.Insert hex bolt

2.Place the hex bolt into the hole provided in the left handle. Secure with lock washer and hex nut. Do not tighten until after attaching the other end of the chute crank.

3.To align the spiral on the chute crank, it may be necessary to loosen the carriage bolts and hex lock nuts which secure the lower chute crank bracket to the extension on the left side of the chute assembly. See Figure 9.

4.Place one flat washer on the end of the chute crank, then insert the end of the crank into the hole in the plastic bushing in the chute crank bracket. See Figure 10. Place another flat washer on the end of the chute crank, and insert hairpin clip into hole in the end of crank.

5.Adjust the chute bracket so that the spiral on the chute crank fully engages the teeth on the chute assembly. Tighten the nuts on the lower chute crank bracket securely. Tighten the hex bolt and nut on the upper chute crank bracket on the handle.

8