MC-62P/S CONCRETE MIXER — GENERAL INFORMATION

Application

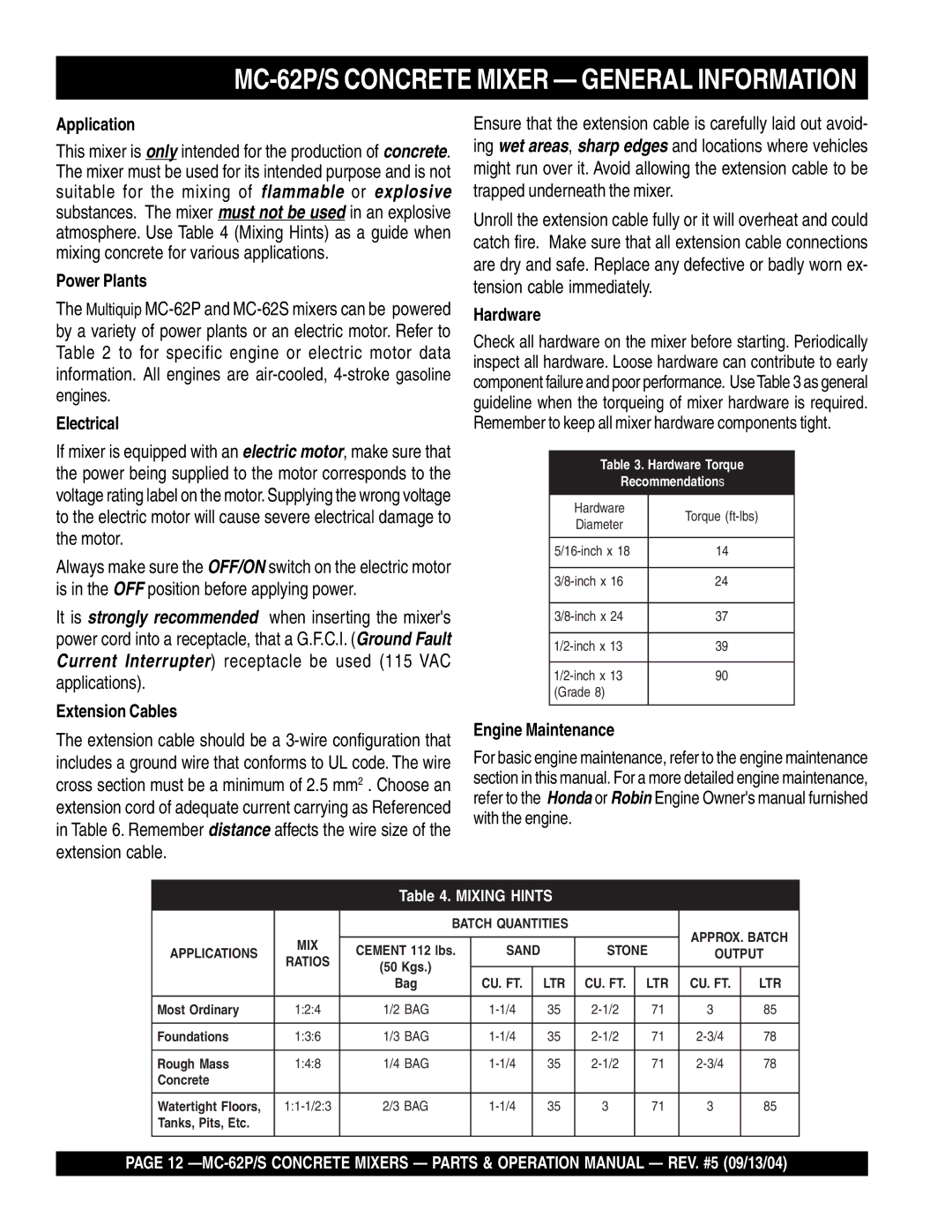

This mixer is only intended for the production of concrete. The mixer must be used for its intended purpose and is not suitable for the mixing of flammable or explosive substances. The mixer must not be used in an explosive atmosphere. Use Table 4 (Mixing Hints) as a guide when mixing concrete for various applications.

Power Plants

The Multiquip

Electrical

Ensure that the extension cable is carefully laid out avoid- ing wet areas, sharp edges and locations where vehicles might run over it. Avoid allowing the extension cable to be trapped underneath the mixer.

Unroll the extension cable fully or it will overheat and could catch fire. Make sure that all extension cable connections are dry and safe. Replace any defective or badly worn ex- tension cable immediately.

Hardware

Check all hardware on the mixer before starting. Periodically inspect all hardware. Loose hardware can contribute to early component failure and poor performance. UseTable 3 as general guideline when the torqueing of mixer hardware is required. Remember to keep all mixer hardware components tight.

If mixer is equipped with an electric motor, make sure that the power being supplied to the motor corresponds to the voltage rating label on the motor.Supplying the wrong voltage to the electric motor will cause severe electrical damage to the motor.

Always make sure the OFF/ON switch on the electric motor is in the OFF position before applying power.

It is strongly recommended when inserting the mixer's power cord into a receptacle, that a G.F.C.I. (Ground Fault Current Interrupter) receptacle be used (115 VAC applications).

Extension Cables

The extension cable should be a

Table 3. Hardware Torque

Recommendations

Hardware | Torque | |

Diameter | ||

| ||

|

| |

14 | ||

|

| |

24 | ||

|

| |

37 | ||

|

| |

39 | ||

|

| |

90 | ||

(Grade 8) |

| |

|

|

Engine Maintenance

For basic engine maintenance, refer to the engine maintenance section in this manual. For a more detailed engine maintenance, refer to the Honda or Robin Engine Owner's manual furnished with the engine.

Table 4. MIXING HINTS

|

| BATCH QUANTITIES |

|

| APPROX. BATCH | ||||

| MIX |

|

|

|

|

|

| ||

APPLICATIONS | CEMENT 112 lbs. | SAND |

| STONE | |||||

| OUTPUT | ||||||||

RATIOS |

| ||||||||

| (50 Kgs.) |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |

|

| Bag | CU. FT. |

| LTR | CU. FT. | LTR | CU. FT. | LTR |

|

|

|

|

|

|

|

|

|

|

Most Ordinary | 1:2:4 | 1/2 BAG |

| 35 | 71 | 3 | 85 | ||

|

|

|

|

|

|

|

|

|

|

Foundations | 1:3:6 | 1/3 BAG |

| 35 | 71 | 78 | |||

|

|

|

|

|

|

|

|

|

|

Rough Mass | 1:4:8 | 1/4 BAG |

| 35 | 71 | 78 | |||

Concrete |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Watertight Floors, | 2/3 BAG |

| 35 | 3 | 71 | 3 | 85 | ||

Tanks, Pits, Etc. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PAGE 12