Models

Proposition 65WARNING

Page

MC-92P/S Concrete Mixer Table of Contents

MC-92P/S Concrete Mixer Parts Ordering Procedures

Best Deal! Order via Internet Dealers Only

Order via Fax Dealers Only

Specifications Engines/Electric Motor

MC-92P/S Concrete Mixer Specifications

Mixer Dimensions

MC-92P/S Concrete Mixer Dimensions Mixer

Foryour Safety and the Safety of Others

MC-92P/S Concrete Mixer Safety Message Alert Symbols

MC-92P/S Concrete Mixer Rules for Safe Operation

General Safety

Emergencies

MC-92P/S Concrete Mixer Rules for Safe Operation

Machine Safety Decals

MC-92P/S Concrete Mixer Operation and Safety Decals

MC-92P/S Concrete Mixer General Information

Mixer Major Components

MC-92P/S Concrete Mixer Mixer Basic Components

Engine Controls and Components

MC-92P/S Concrete Mixer Basic Engine Components

Assembly

MC-92P/S Concrete Mixer Handwheel Assembly

Mixer Tow Bar Vehicle Connection Pintle and Loop

Tow Bar to Vehicle Connection Coupler Only

Tow Bar to Mixer Connection

MC-92P/S Concrete Mixer Safety Chain Connection

MC-92P/S Concrete Mixer Electric Motor

Electric MotorVoltage Change Switch

Electric Motor

Electric Motor Connection

MC-92P/S Concrete Mixer Electric Motor

Single Phase Electric Motor with 12 inch Pigtail Cable

MC-92P/S Concrete Mixer PRE-INSPECTION GAS Engine

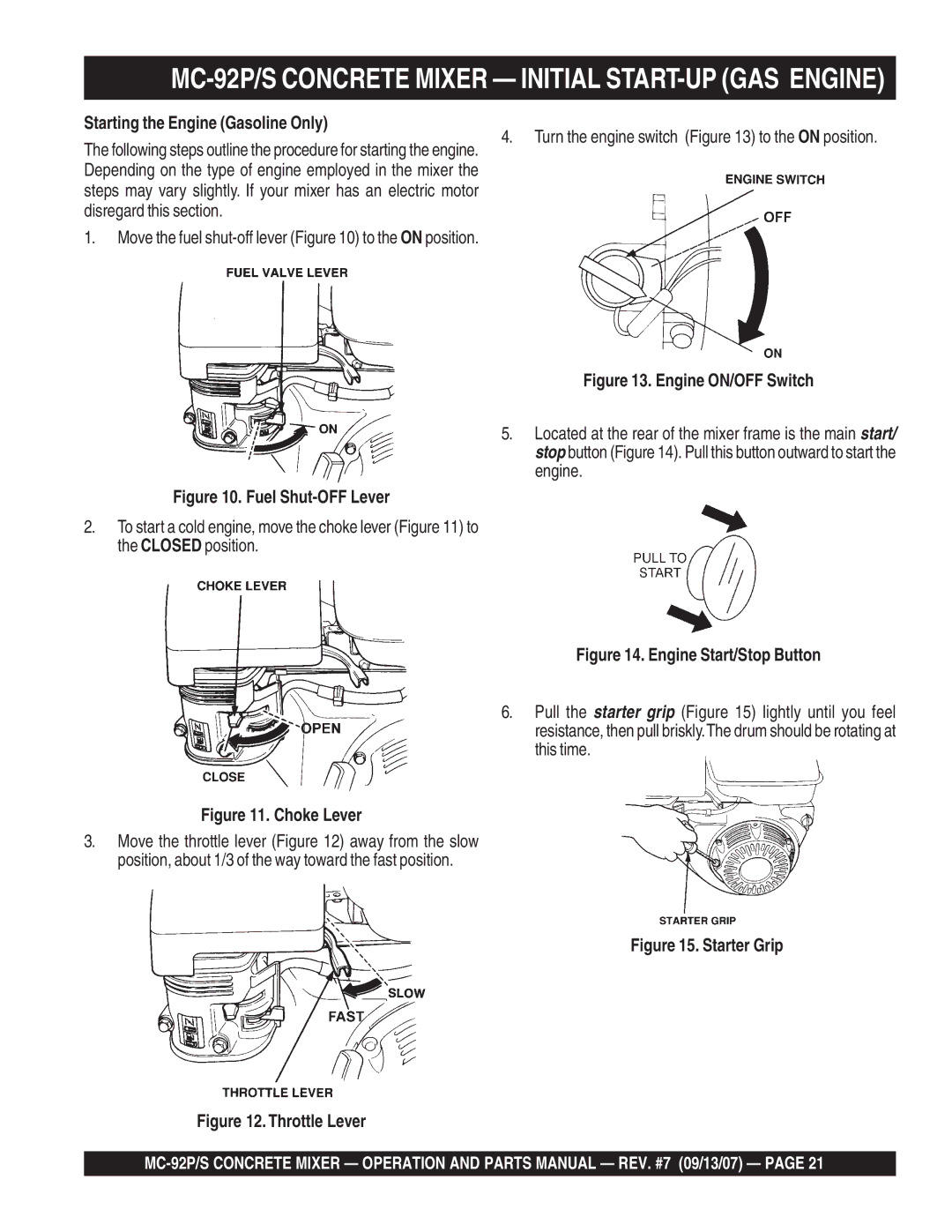

Starting the Engine Gasoline Only

MC-92P/S Concrete Mixer Initial START-UP GAS Engine

MC-92P/S Concrete Mixer Initial START-UP Electric Motor

Initial Start-up Instructions Electric Motor Starting

Starting the Electric Motor

MC-92P/S Concrete Mixer Operation

Operation

Stopping the Mixer Electric

Engine Maintenance Schedule

MC-92P/S Concrete Mixer Maintenance Engine

Maintenance

MC-92P/S Concrete Mixer Maintenance Engine

MC-92P/S Concrete Mixer Maintenance Mixer

Suspension Components

MC-92P/S Concrete Mixer Maintenance Mixer

To tighten wheel lug nuts

Page

Engine Troubleshooting

MC-92P/S Concrete Mixer Troubleshooting Engine

Engine Troubleshooting

MC-92P/S Concrete Mixer Troubleshooting ENGINE/MIXER

NO. Column

Explanation of Code in Remarks Column

Part NO. Column

QTY. Column

Qty Description

MC-92P/S Concrete Mixer Suggested Spare Parts

Name Plate and Decals

MC-92P/S Concrete Mixer Name Plate and Decals

MC-92P/S Concrete MIXER- Name Plate and Decals

Plastic Barrel Assy

MC-92P/S Plastic Barrel

Ring Gear

HOUSING, Jackshaft

NUT, Lock 3/8 NC

PLUG, Expansion

Steel Barrel Assy

MC-92P/S Steel Barrel

Shim 0.10 Thick

BARREL, Steel 9 CU. FT

Shim 0.14 Thick

Shim 0.187 Thick

Main Frame Assy

MC-92P/S Main Frame Assembly

Connector Link

Handwheel Safety Chain

GUARD, Gear Wheel

WASHER, Lock 1/4

Axle Assy

MC-92P/S Axle Assembly

Spring Support

Lock NUT 5/8 NC

Spring Leaf

Axle 1-1/16 Spindle

Cabinet Assy

MC-92P/S Cabinet Assembly

CABINET, Engine Assy

Rubber Protector

WASHER, Flat 5/16

Latch ASSY., Complete

GAS Engine Mounting Plate Assy

MC-92P/S GAS Engine Mounting Plate Assembly

ENGINE, Robin 8.5 HP

ENGINE, Honda 8.0 HP

RING, Retaining

Square KEY

Electric Motor Mounting Plate Assy

MC-92P/S Electric Motor Mounting Plate Assembly

MOTOR, Electric 1.5 HP

AIR Cleaner Assy

Honda GX240K1HA2 Engine AIR Cleaner Assy

COVER, AIR Cleaner

ELEMENT, AIR CLEANER, Dual

GROMMET, AIR Cleaner

COLLAR, AIR Cleaner

Camshaft Assy

Honda GX240K1HA2 Engine Camshaft Assy

Camshaft

SPRING, Weight Return

ROD Push

ARM Valve Rocker

Carburetor Assy

Honda GX240K1HA2 Engine Carburetor Assy

Gasket SET

PLATE, Lever Setting

Valve SET, Float

Float SET

Control Assy

Honda GX240K1HA2 Engine Control Assy

ROD, Governor

ARM, Governor

SPRING, Governor

SPRING, Throttle Return

Crankcase Cover Assy

Honda GX240K1HA2 Engine Crankcase Cover Assy

HOLDER, Governor Weight

WEIGHT, Governor

PIN, Governor Weight

Type Balancer

Crankshaft Assy

Honda GX240K1HA2ENGINE Crankshaft Assy

Weight Balancer

Cylinder Barrel Assy

Honda GX240K1HA2 Engine Cylinder Barrel Assy

SHAFT, Governor ARM

Switch ASSY., OIL Level

BOLT, Drain Plug

Ring 14MM Arai

Cylinder Head Assy

Honda GX240K1HA2 Engine Cylinder Head Assy

GUIDE, EX. VALVE, OS, Optional

GUIDE, VALVE, OS, Optional

CLIP, Valve Guide

GASKET, Cylinder Head

FAN Cover Assy

Honda GX240K1HA2 Engine FAN Cover Assy

CLIP, Wire Harness

Switch ASSY., Engine Stop

CLIP, Tube

Shroud

Flywheel Assy

Honda GX240K1HA2 Engine Flywheel Assy

Flywheel Comp

FAN, Cooling

NUT, Special 16MM

KEY, Special Woodruff

Muffler Assy

Honda GX240K1HA2 Engine Muffler Assy

PROTECTOR, Muffler

Muffler

PROTECTOR, EX. Pipe

PIPE, EX

Fuel Tank Assy

Honda GX240K1HA2 Engine Fueltank Assy

JOINT, Fuel Tank

Rubber Supporter 107MM

Tank COMP., Fuel *NH1*, Black

GASKET, Fuel Filler CAP

Ignition Coil Assy

Honda GX240K1HA2ENGINE Ignition Assy

WIRE, Stop Switch 370MM

GROMMET, Wire

Coil ASSY., Ignition

CAP ASSY., Noise Suppressor

Piston Assy

Honda GX240K1HA2 Engine Piston Assy

Ring SET, PISTON, STD

BOLT, Connecting ROD

Ring SET, PISTON, 0.75, Optional

PISTON, Standard

Recoil Starter Assy

Honda GX240K1HA2 Engine Recoil Starter Assy

RATCHET, Starter

PULLEY, Recoil Starter

SPRING, Friction

SPRING, Starter Return

Gear Reduction Assy

Honda GX240K1HA2 Engine Gear Reduction Assy

Countershaft

GEAR, Primary Drive 17T

SHAFT, P.T.O. H- Type

Shim a Optional

Label Assy

Honda GX240K1HA2 Engine Label Assy

EMBLEM, Internal

Labels Assy

MARK, CAUTION, External

LABEL, Caution

Freight Policy

Terms and Conditions of Sale Parts

Page

HERE’S HOW to GET Help