This section is intended to assist the operator with the initial

DO NOT use your rammer until this section is thoroughly understood.

MTX70 — OPERATION

Engine

1.Fill the fuel tank (Figure 3) with unleaded gasoline. At the same time, check the engine oil and make it a habit to replenish it often (Figure 4).

![]() CAUTION

CAUTION

Failure to understand the operation of the MTX70Tamping Rammer could result in severe damage to the unit or personal injury.

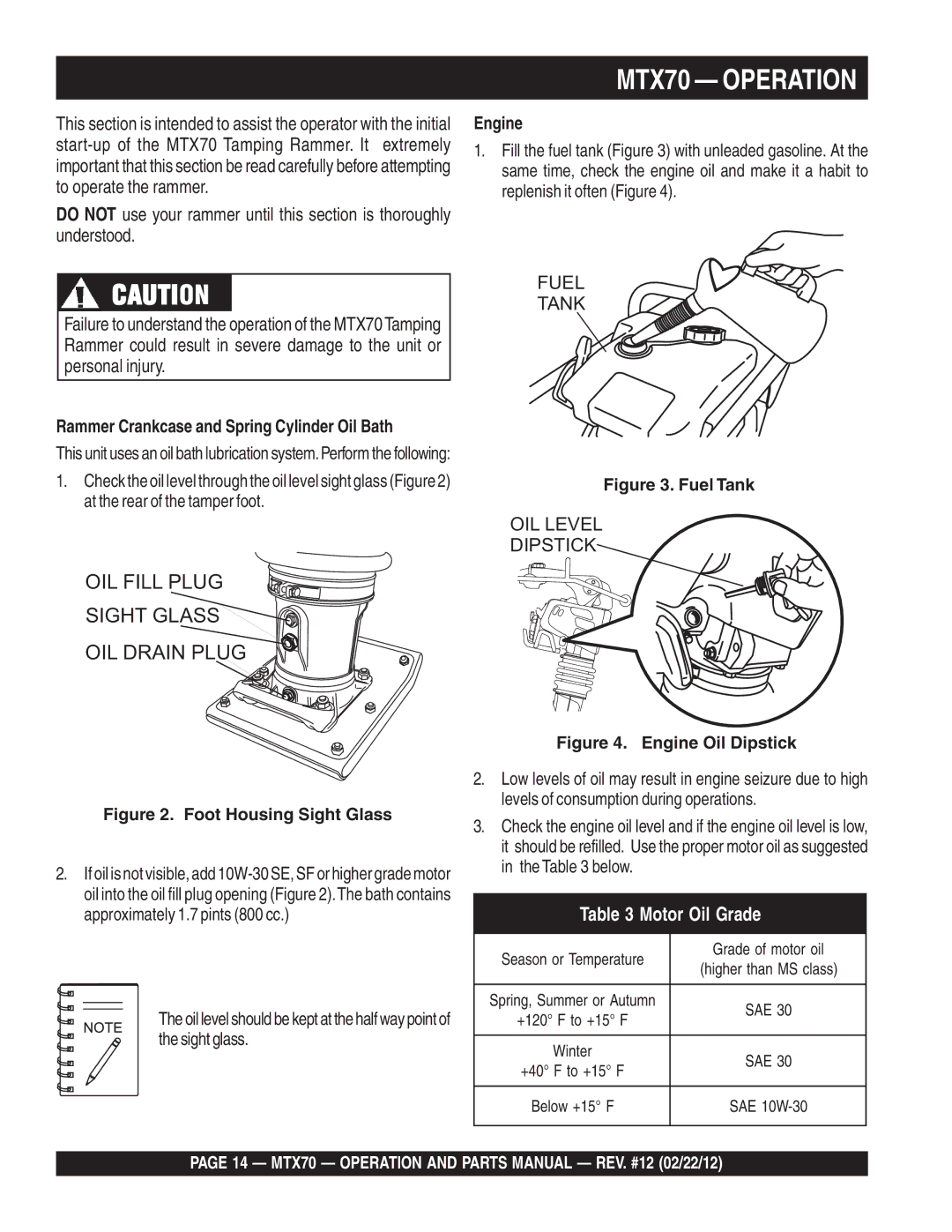

Rammer Crankcase and Spring Cylinder Oil Bath

This unit uses an oil bath lubrication system.Perform the following:

1.Check the oil level through the oil level sight glass (Figure 2) at the rear of the tamper foot.

OIL FILL PLUG

SIGHT GLASS

OIL DRAIN PLUG

FUEL

TANK

Figure 3. Fuel Tank

OIL LEVEL

DIPSTICK

Figure 2. Foot Housing Sight Glass

2.

The oil level should be kept at the half way point of the sight glass.

Figure 4. Engine Oil Dipstick

2.Low levels of oil may result in engine seizure due to high levels of consumption during operations.

3.Check the engine oil level and if the engine oil level is low, it should be refilled. Use the proper motor oil as suggested in the Table 3 below.

Table 3 Motor Oil Grade

Season or Temperature | Grade of motor oil | ||

(higher than MS class) | |||

|

| ||

|

| ||

Spring, Summer or Autumn | SAE 30 | ||

+120° F to +15° F | |||

| |||

|

|

| |

Winter |

| SAE 30 | |

+40° F to +15° | F | ||

| |||

|

|

| |

Below +15° F |

| SAE | |

|

|

| |