|

|

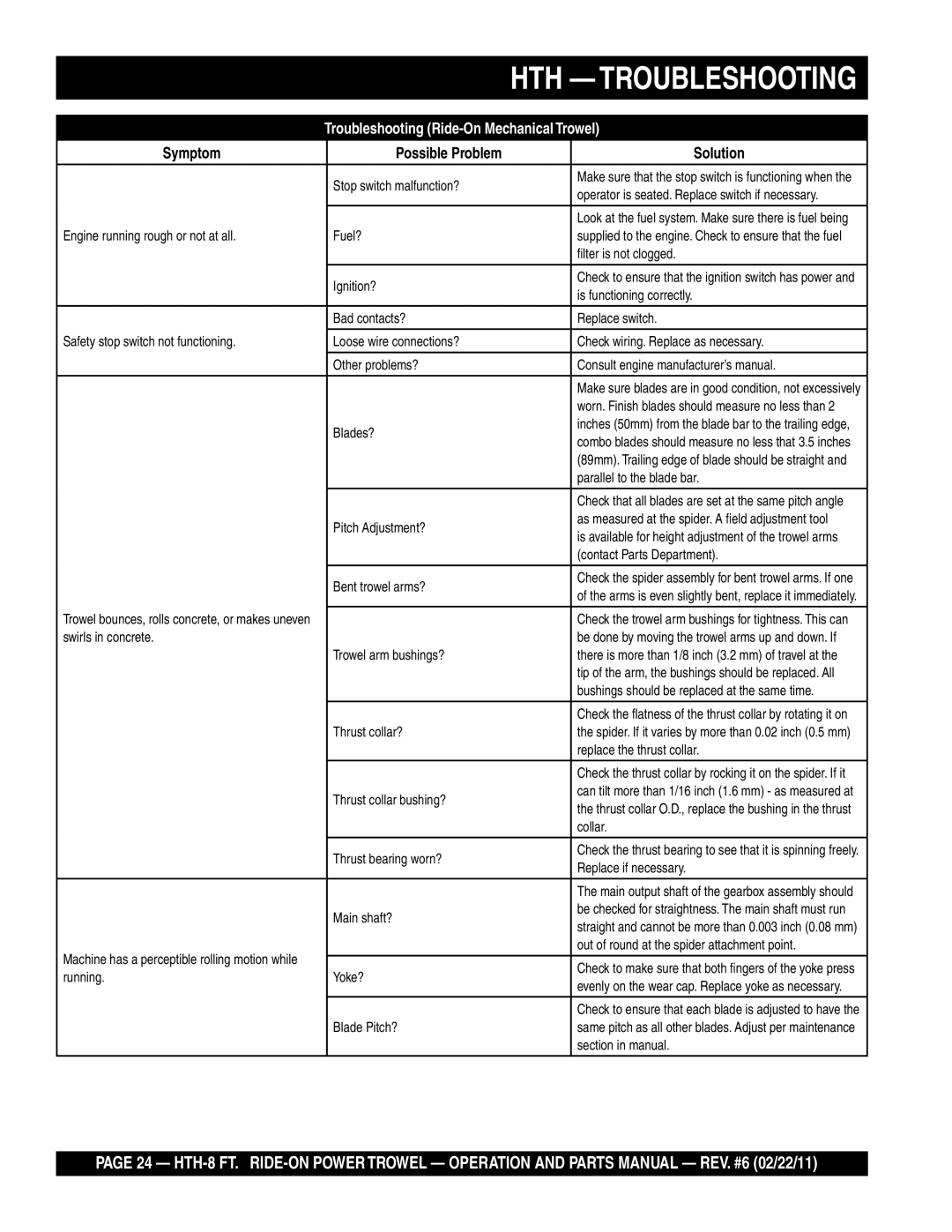

| HTH — TROUBLESHOOTING | |

|

|

|

| |

| Troubleshooting | |||

Symptom |

| Possible Problem |

| Solution |

|

| Stop switch malfunction? |

| Make sure that the stop switch is functioning when the |

|

|

| operator is seated. Replace switch if necessary. | |

|

|

|

| |

|

|

|

|

|

|

|

|

| Look at the fuel system. Make sure there is fuel being |

Engine running rough or not at all. |

| Fuel? |

| supplied to the engine. Check to ensure that the fuel |

|

|

|

| filter is not clogged. |

|

|

|

|

|

|

| Ignition? |

| Check to ensure that the ignition switch has power and |

|

|

| is functioning correctly. | |

|

|

|

| |

|

|

|

|

|

|

| Bad contacts? |

| Replace switch. |

|

|

|

|

|

Safety stop switch not functioning. |

| Loose wire connections? |

| Check wiring. Replace as necessary. |

|

|

|

|

|

|

| Other problems? |

| Consult engine manufacturer’s manual. |

|

|

|

|

|

|

|

|

| Make sure blades are in good condition, not excessively |

|

|

|

| worn. Finish blades should measure no less than 2 |

|

| Blades? |

| inches (50mm) from the blade bar to the trailing edge, |

|

|

| combo blades should measure no less that 3.5 inches | |

|

|

|

| |

|

|

|

| (89mm). Trailing edge of blade should be straight and |

|

|

|

| parallel to the blade bar. |

|

|

|

|

|

|

|

|

| Check that all blades are set at the same pitch angle |

|

| Pitch Adjustment? |

| as measured at the spider. A field adjustment tool |

|

|

| is available for height adjustment of the trowel arms | |

|

|

|

| |

|

|

|

| (contact Parts Department). |

|

|

|

|

|

|

| Bent trowel arms? |

| Check the spider assembly for bent trowel arms. If one |

|

|

| of the arms is even slightly bent, replace it immediately. | |

|

|

|

| |

Trowel bounces, rolls concrete, or makes uneven |

|

|

|

|

|

|

| Check the trowel arm bushings for tightness. This can | |

swirls in concrete. |

|

|

| be done by moving the trowel arms up and down. If |

|

| Trowel arm bushings? |

| there is more than 1/8 inch (3.2 mm) of travel at the |

|

|

|

| tip of the arm, the bushings should be replaced. All |

|

|

|

| bushings should be replaced at the same time. |

|

|

|

|

|

|

|

|

| Check the flatness of the thrust collar by rotating it on |

|

| Thrust collar? |

| the spider. If it varies by more than 0.02 inch (0.5 mm) |

|

|

|

| replace the thrust collar. |

|

|

|

|

|

|

|

|

| Check the thrust collar by rocking it on the spider. If it |

|

| Thrust collar bushing? |

| can tilt more than 1/16 inch (1.6 mm) - as measured at |

|

|

| the thrust collar O.D., replace the bushing in the thrust | |

|

|

|

| |

|

|

|

| collar. |

|

|

|

|

|

|

| Thrust bearing worn? |

| Check the thrust bearing to see that it is spinning freely. |

|

|

| Replace if necessary. | |

|

|

|

| |

|

|

|

| The main output shaft of the gearbox assembly should |

|

| Main shaft? |

| be checked for straightness. The main shaft must run |

|

|

| straight and cannot be more than 0.003 inch (0.08 mm) | |

|

|

|

| |

Machine has a perceptible rolling motion while |

|

|

| out of round at the spider attachment point. |

|

|

| Check to make sure that both fingers of the yoke press | |

running. |

| Yoke? |

| |

|

| evenly on the wear cap. Replace yoke as necessary. | ||

|

|

|

| |

|

|

|

|

|

|

|

|

| Check to ensure that each blade is adjusted to have the |

|

| Blade Pitch? |

| same pitch as all other blades. Adjust per maintenance |

|

|

|

| section in manual. |

|

|

|

|

|

PAGE 24 —