ASSEMBLY INSTRUCTIONS/OPERATION

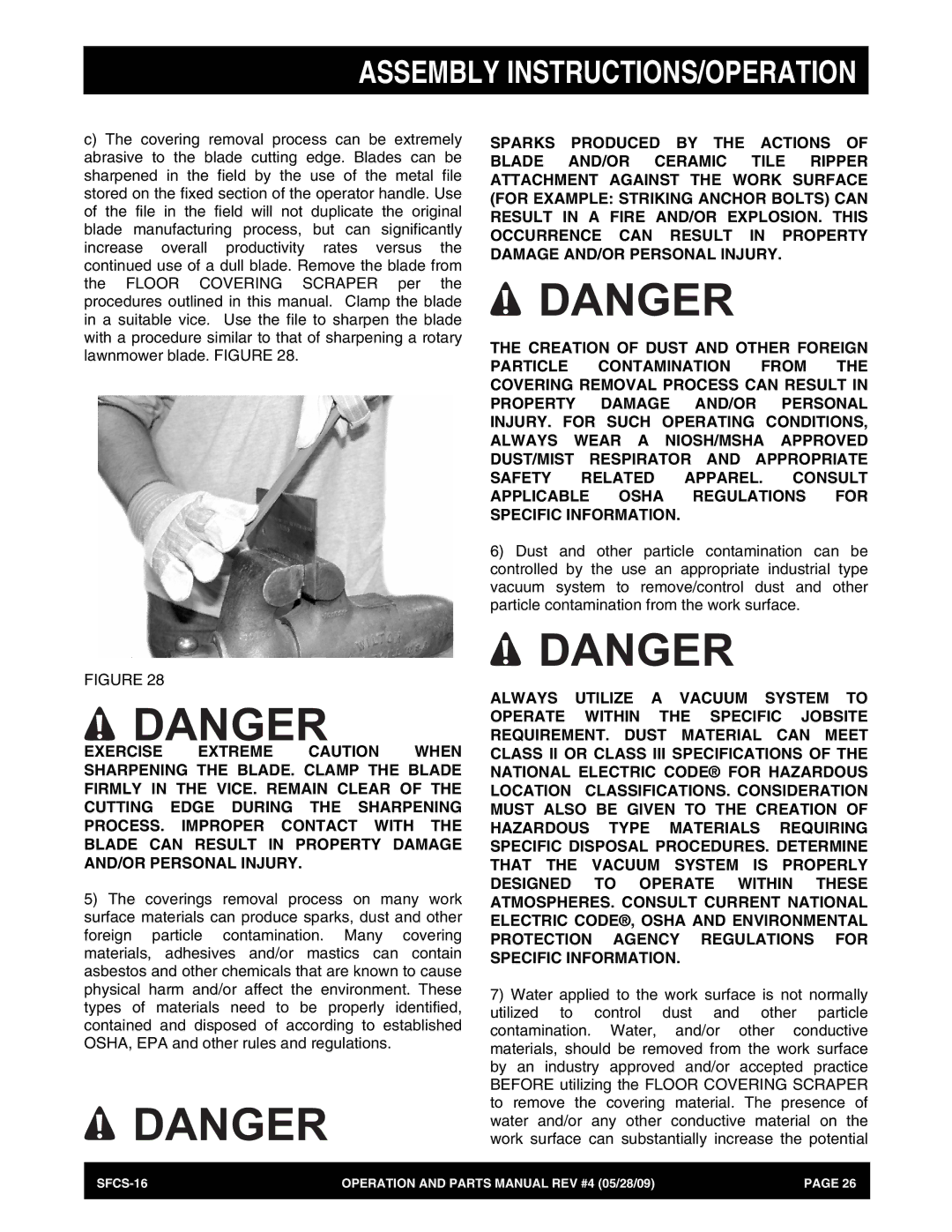

c)The covering removal process can be extremely abrasive to the blade cutting edge. Blades can be sharpened in the field by the use of the metal file stored on the fixed section of the operator handle. Use of the file in the field will not duplicate the original blade manufacturing process, but can significantly increase overall productivity rates versus the continued use of a dull blade. Remove the blade from the FLOOR COVERING SCRAPER per the procedures outlined in this manual. Clamp the blade in a suitable vice. Use the file to sharpen the blade with a procedure similar to that of sharpening a rotary lawnmower blade. FIGURE 28.

FIGURE 28

![]() DANGER

DANGER

EXERCISE EXTREME CAUTION WHEN SHARPENING THE BLADE. CLAMP THE BLADE FIRMLY IN THE VICE. REMAIN CLEAR OF THE CUTTING EDGE DURING THE SHARPENING PROCESS. IMPROPER CONTACT WITH THE BLADE CAN RESULT IN PROPERTY DAMAGE AND/OR PERSONAL INJURY.

5)The coverings removal process on many work surface materials can produce sparks, dust and other foreign particle contamination. Many covering materials, adhesives and/or mastics can contain asbestos and other chemicals that are known to cause physical harm and/or affect the environment. These types of materials need to be properly identified, contained and disposed of according to established OSHA, EPA and other rules and regulations.

![]() DANGER

DANGER

SPARKS PRODUCED BY THE ACTIONS OF BLADE AND/OR CERAMIC TILE RIPPER ATTACHMENT AGAINST THE WORK SURFACE (FOR EXAMPLE: STRIKING ANCHOR BOLTS) CAN RESULT IN A FIRE AND/OR EXPLOSION. THIS OCCURRENCE CAN RESULT IN PROPERTY DAMAGE AND/OR PERSONAL INJURY.

![]() DANGER

DANGER

THE CREATION OF DUST AND OTHER FOREIGN PARTICLE CONTAMINATION FROM THE COVERING REMOVAL PROCESS CAN RESULT IN PROPERTY DAMAGE AND/OR PERSONAL INJURY. FOR SUCH OPERATING CONDITIONS, ALWAYS WEAR A NIOSH/MSHA APPROVED DUST/MIST RESPIRATOR AND APPROPRIATE SAFETY RELATED APPAREL. CONSULT APPLICABLE OSHA REGULATIONS FOR SPECIFIC INFORMATION.

6)Dust and other particle contamination can be controlled by the use an appropriate industrial type vacuum system to remove/control dust and other particle contamination from the work surface.

![]() DANGER

DANGER

ALWAYS UTILIZE A VACUUM SYSTEM TO OPERATE WITHIN THE SPECIFIC JOBSITE REQUIREMENT. DUST MATERIAL CAN MEET CLASS II OR CLASS III SPECIFICATIONS OF THE NATIONAL ELECTRIC CODE® FOR HAZARDOUS LOCATION CLASSIFICATIONS. CONSIDERATION MUST ALSO BE GIVEN TO THE CREATION OF HAZARDOUS TYPE MATERIALS REQUIRING SPECIFIC DISPOSAL PROCEDURES. DETERMINE THAT THE VACUUM SYSTEM IS PROPERLY DESIGNED TO OPERATE WITHIN THESE ATMOSPHERES. CONSULT CURRENT NATIONAL ELECTRIC CODE®, OSHA AND ENVIRONMENTAL PROTECTION AGENCY REGULATIONS FOR SPECIFIC INFORMATION.

7)Water applied to the work surface is not normally utilized to control dust and other particle contamination. Water, and/or other conductive materials, should be removed from the work surface by an industry approved and/or accepted practice BEFORE utilizing the FLOOR COVERING SCRAPER to remove the covering material. The presence of water and/or any other conductive material on the work surface can substantially increase the potential

| OPERATION AND PARTS MANUAL REV #4 (05/28/09) | PAGE 26 |

|

|

|