ASSEMBLY INSTRUCTIONS/OPERATION

b)To lubricate the exciter bearing housing casting. The exciter unit utilizes a sealed type ball bearing. The Zerk® fitting provides lubrication for the

Sleeve type bearings are

9)Determine that all safety decals and operational information decals (including the applicable Quik Tips information) is in proper and readable condition. Replace any missing or damaged safety decal and/or information decal with a factory approved replacement part only.

10)The FLOOR COVERING SCRAPER utilizes antivibration handle grips on the operator handle to enhance control and help dampen the forces experienced during the covering removal process. Determine the handle is equipped with properly fitting handle grips of sufficient integrity to allow for proper job function as outlined in this manual. Loose fitting handle grips or grips without end caps should be replaced with factory approved replacement parts only.

![]() DANGER

DANGER

DO NOT OPERATE THE FLOOR COVERING SCRAPER WITHOUT PROPERLY FITTED HANDLE GRIPS OF SUFFICIENT INTEGRITY INSTALLED ON THE OPERATOR HANDLE. OPERATING THE FLOOR COVERING SCRAPER WITH IMPROPER OR NO HANDLE GRIPS CAN RESULT IN PROPERTY DAMAGE AND/OR PERSONAL INJURY.

LUBRICATION REQUIREMENTS.

Parts Required:

1each, standard grease gun filled with one of the following: ESSO Beacon 325, Shell Alvania #2, Chevron SRI, or equivalent.

1 each, container of dry film lubricant.

1)Lubricate the caster wheel bearings with a dry film lubricant only. Dry film lubricants dry immediately upon contact. Use sparingly. Excess lubricant will attract the fine grained, powdered materials described and directly affect bearing service life.

![]() CAUTION

CAUTION

Do not lubricate the caster wheels with any lubricant other than a dry film type. Grease and many other liquid type lubricants will attract foreign material accumulations that can reduce bearing service life.

2)Zerk™ type grease fittings are provided at two locations:

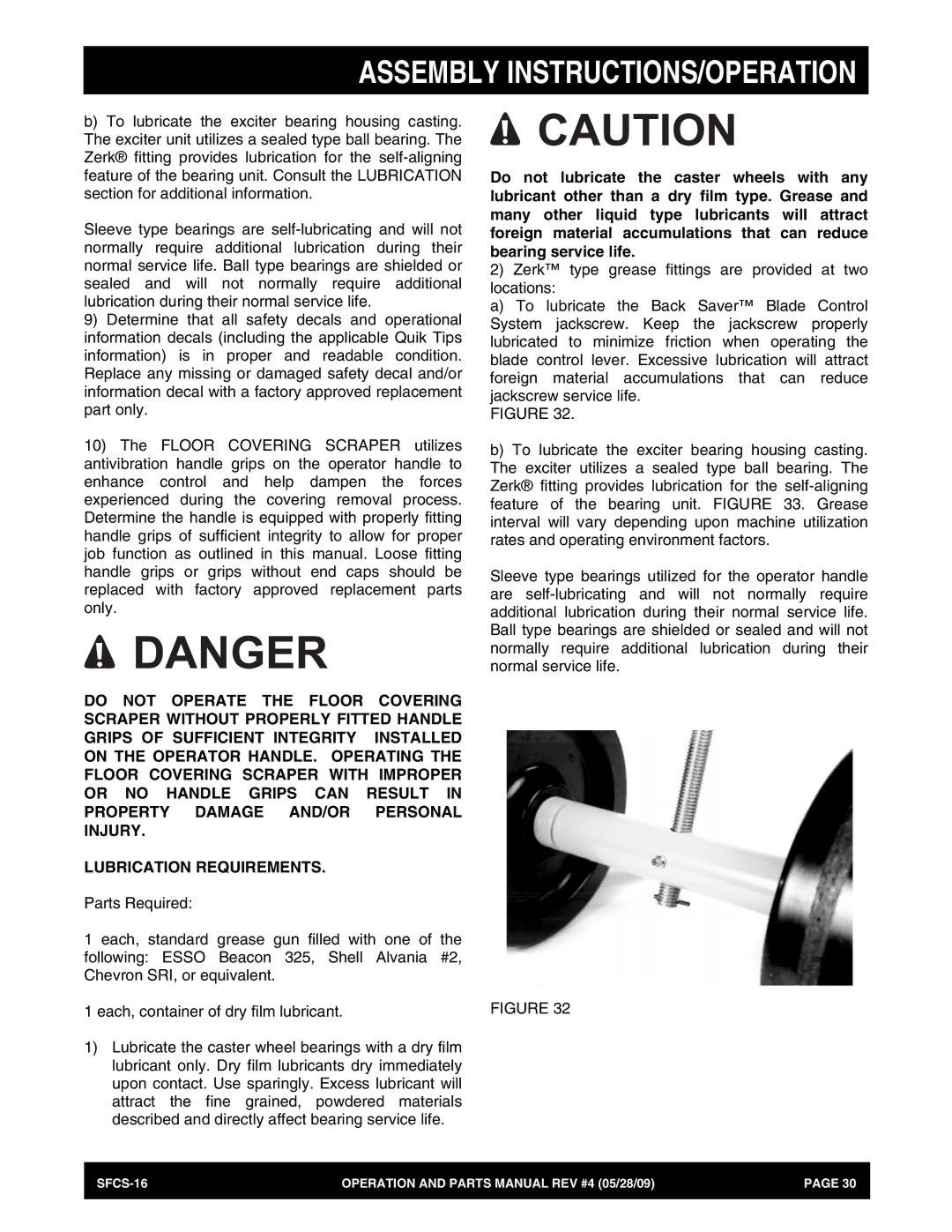

a) To lubricate the Back Saver™ Blade Control System jackscrew. Keep the jackscrew properly lubricated to minimize friction when operating the blade control lever. Excessive lubrication will attract foreign material accumulations that can reduce jackscrew service life.

FIGURE 32.

b)To lubricate the exciter bearing housing casting. The exciter utilizes a sealed type ball bearing. The Zerk® fitting provides lubrication for the

Sleeve type bearings utilized for the operator handle are

FIGURE 32

| OPERATION AND PARTS MANUAL REV #4 (05/28/09) | PAGE 30 |

|

|

|