OPERATION AND MAINTENANCE

Operation

MeCAN begins transmitting J1939 CANbus data immediately after

Engine oil pressure and coolant temperature

Model 79.70.0014 transmits pressure and temperature data when the sender input is within normal resistance range. MeCAN also transmits appropriate SPN (Suspect Parameter Number) and FMI (Fault Mode Indicator) codes if:

•input resistance is out of normal sender range, e.g. open- or

•oil pressure drops below 20 psi (warning message) and 10 psi (shutdown/derate message)

•coolant temperature rises above 90°C/194°F (warning message) or 110°C/230°F (shutdown message)

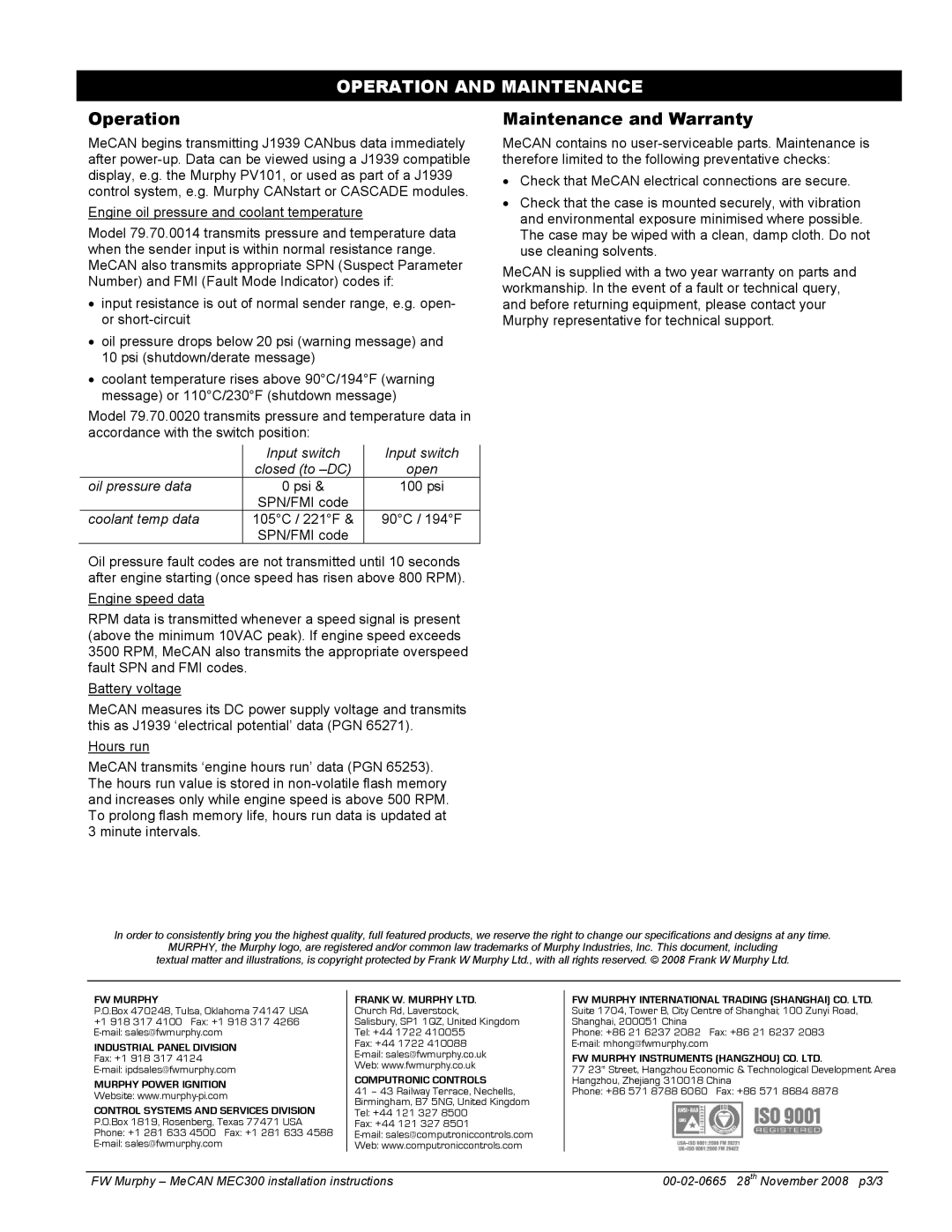

Model 79.70.0020 transmits pressure and temperature data in accordance with the switch position:

Maintenance and Warranty

MeCAN contains no

•Check that MeCAN electrical connections are secure.

•Check that the case is mounted securely, with vibration and environmental exposure minimised where possible. The case may be wiped with a clean, damp cloth. Do not use cleaning solvents.

MeCAN is supplied with a two year warranty on parts and workmanship. In the event of a fault or technical query, and before returning equipment, please contact your Murphy representative for technical support.

| Input switch | Input switch |

| closed (to | open |

oil pressure data | 0 psi & | 100 psi |

| SPN/FMI code |

|

coolant temp data | 105°C / 221°F & | 90°C / 194°F |

| SPN/FMI code |

|

Oil pressure fault codes are not transmitted until 10 seconds after engine starting (once speed has risen above 800 RPM).

Engine speed data

RPM data is transmitted whenever a speed signal is present (above the minimum 10VAC peak). If engine speed exceeds 3500 RPM, MeCAN also transmits the appropriate overspeed fault SPN and FMI codes.

Battery voltage

MeCAN measures its DC power supply voltage and transmits this as J1939 ‘electrical potential’ data (PGN 65271).

Hours run

MeCAN transmits ‘engine hours run’ data (PGN 65253). The hours run value is stored in

In order to consistently bring you the highest quality, full featured products, we reserve the right to change our specifications and designs at any time.

MURPHY, the Murphy logo, are registered and/or common law trademarks of Murphy Industries, Inc. This document, including

textual matter and illustrations, is copyright protected by Frank W Murphy Ltd., with all rights reserved. © 2008 Frank W Murphy Ltd.

FW MURPHY

P.O.Box 470248, Tulsa, Oklahoma 74147 USA +1 918 317 4100 Fax: +1 918 317 4266

INDUSTRIAL PANEL DIVISION Fax: +1 918 317 4124

MURPHY POWER IGNITION

Website:

CONTROL SYSTEMS AND SERVICES DIVISION P.O.Box 1819, Rosenberg, Texas 77471 USA Phone: +1 281 633 4500 Fax: +1 281 633 4588

FRANK W. MURPHY LTD. Church Rd, Laverstock,

Salisbury, SP1 1QZ, United Kingdom Tel: +44 1722 410055

Fax: +44 1722 410088

Web: www.fwmurphy.co.uk

COMPUTRONIC CONTROLS

41 – 43 Railway Terrace, Nechells, Birmingham, B7 5NG, United Kingdom Tel: +44 121 327 8500

Fax: +44 121 327 8501

Web: www.computroniccontrols.com

FW MURPHY INTERNATIONAL TRADING (SHANGHAI) CO. LTD. Suite 1704, Tower B, City Centre of Shanghai; 100 Zunyi Road, Shanghai, 200051 China

Phone: +86 21 6237 2082 Fax: +86 21 6237 2083

FW MURPHY INSTRUMENTS (HANGZHOU) CO. LTD.

77 23rd Street, Hangzhou Economic & Technological Development Area Hangzhou, Zhejiang 310018 China

Phone: +86 571 8788 6060 Fax: +86 571 8684 8878

FW Murphy – MeCAN MEC300 installation instructions |