ELECTRICAL CONNECTION & CONFIGURATION

Electrical connection

MeCAN connection is via 9

RED: Power supply positive DC

BLACK: Power supply negative DC

Connect these wires to a smooth DC power supply in the range 7 to 35 VDC. A 1 Amp

MeCAN operates with negative earth/ground or fully insulated DC systems. DO NOT use MeCAN with positive earth/ground systems.

YELLOW: CANbus high

GREEN: CANbus low

Connect these wires to the engine’s CANbus, using the appropriate

VIOLET: Speed input signal

YELLOW / GREEN: Speed input return

GREY: Speed input calibration (5kOhm potentiometer)

Connect the violet wire to a magnetic pickup or charge alternator speed signal output. Connect the yellow/green wire to the speed signal return wiring (or battery negative, on ground/

Before speed input calibration (see section right), connect a 5kOhm potentiometer between the grey wire and battery negative DC. MeCAN allows adjustment for speed signals between 10 and 180 pulses per engine revolution. The potentiometer can be removed in normal operation.

BLACK: Sender/switch common (negative DC)

WHITE: Coolant temp sender/switch input

ORANGE: Oil pressure sender/switch input

Part number 79.70.0014 is designed for use with Murphy ES series resistive senders: see separate product info for pressure and temperature versus resistance data. For best measurement accuracy, use insulated return

the black (sender common) wire to battery negative.

79.70.0020 is configured for use with switch contacts that close to negative DC on fault. For insulated return

Speed input calibration

MeCAN’s speed sensing input must be correctly calibrated before speed data can be correctly transmitted.

WARNING: speed calibration requires the setting of 2 DIP switches, which are environmentally protected by an adhesive film. To maintain sealing integrity, use a scalpel to carefully lift the film from the DIP switch, make switch adjustments, then replace the film firmly to ensure a good seal.

The speed calibration procedure is as follow:-

a)Ensure minimum connection (details shown left) of CANbus, speed signal and (isolated) DC power supply wiring.

b)Connect a 5 kOhm potentiometer between MeCAN’s calibration input (grey wire) and battery negative DC.

c)Connect (to the CANbus) and

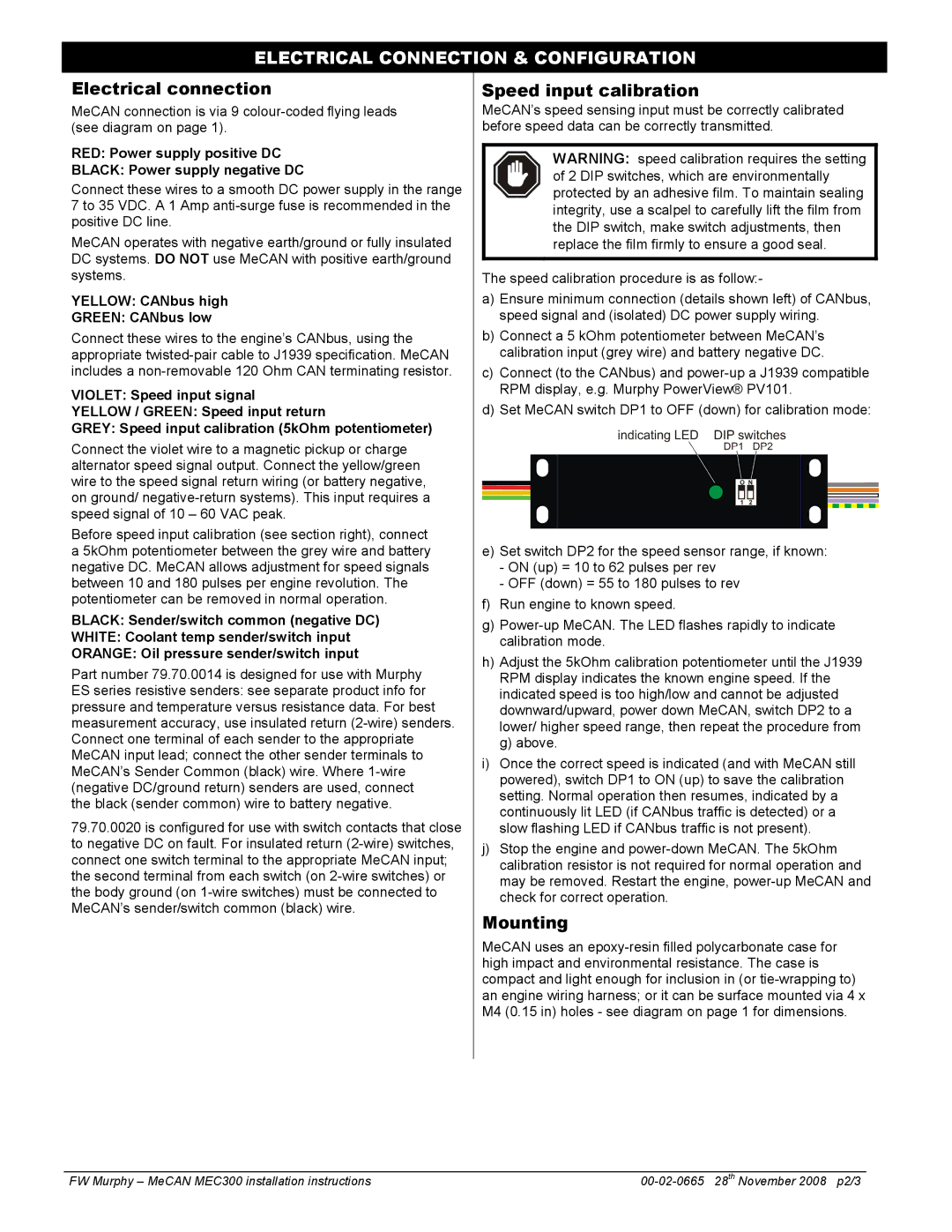

d)Set MeCAN switch DP1 to OFF (down) for calibration mode:

e)Set switch DP2 for the speed sensor range, if known:

-ON (up) = 10 to 62 pulses per rev

-OFF (down) = 55 to 180 pulses to rev

f)Run engine to known speed.

g)

h)Adjust the 5kOhm calibration potentiometer until the J1939 RPM display indicates the known engine speed. If the indicated speed is too high/low and cannot be adjusted downward/upward, power down MeCAN, switch DP2 to a lower/ higher speed range, then repeat the procedure from g) above.

i)Once the correct speed is indicated (and with MeCAN still powered), switch DP1 to ON (up) to save the calibration setting. Normal operation then resumes, indicated by a continuously lit LED (if CANbus traffic is detected) or a slow flashing LED if CANbus traffic is not present).

j)Stop the engine and

Mounting

MeCAN uses an

FW Murphy – MeCAN MEC300 installation instructions |