MGC2000 specifications

The Murphy MGC2000 is a state-of-the-art control system designed for various industrial applications, particularly for monitoring and controlling combustion engines and generators. Renowned for its versatility and reliability, the MGC2000 incorporates advanced technologies that enhance performance and efficiency.One of the main features of the MGC2000 is its dual display capability, allowing users to monitor critical parameters in real-time. The system supports a wide range of sensors and inputs, enabling comprehensive data acquisition. The native graphical interface is user-friendly, making it easy for operators to navigate through various settings and diagnostics, ensuring less downtime and more efficient operation.

Incorporating robust communication protocols, the MGC2000 supports both Modbus RTU and TCP, enhancing the integration of the control system with existing plant equipment and infrastructure. This feature is vital for centralized control operations, as it allows for data exchange between various devices and systems seamlessly.

The Murphy MGC2000 is equipped with advanced diagnostic capabilities, including predictive maintenance features. By monitoring engine performance metrics such as temperature, pressure, and vibration, the system can alert operators to potential issues before they escalate into significant problems, thereby reducing service costs and enhancing equipment longevity.

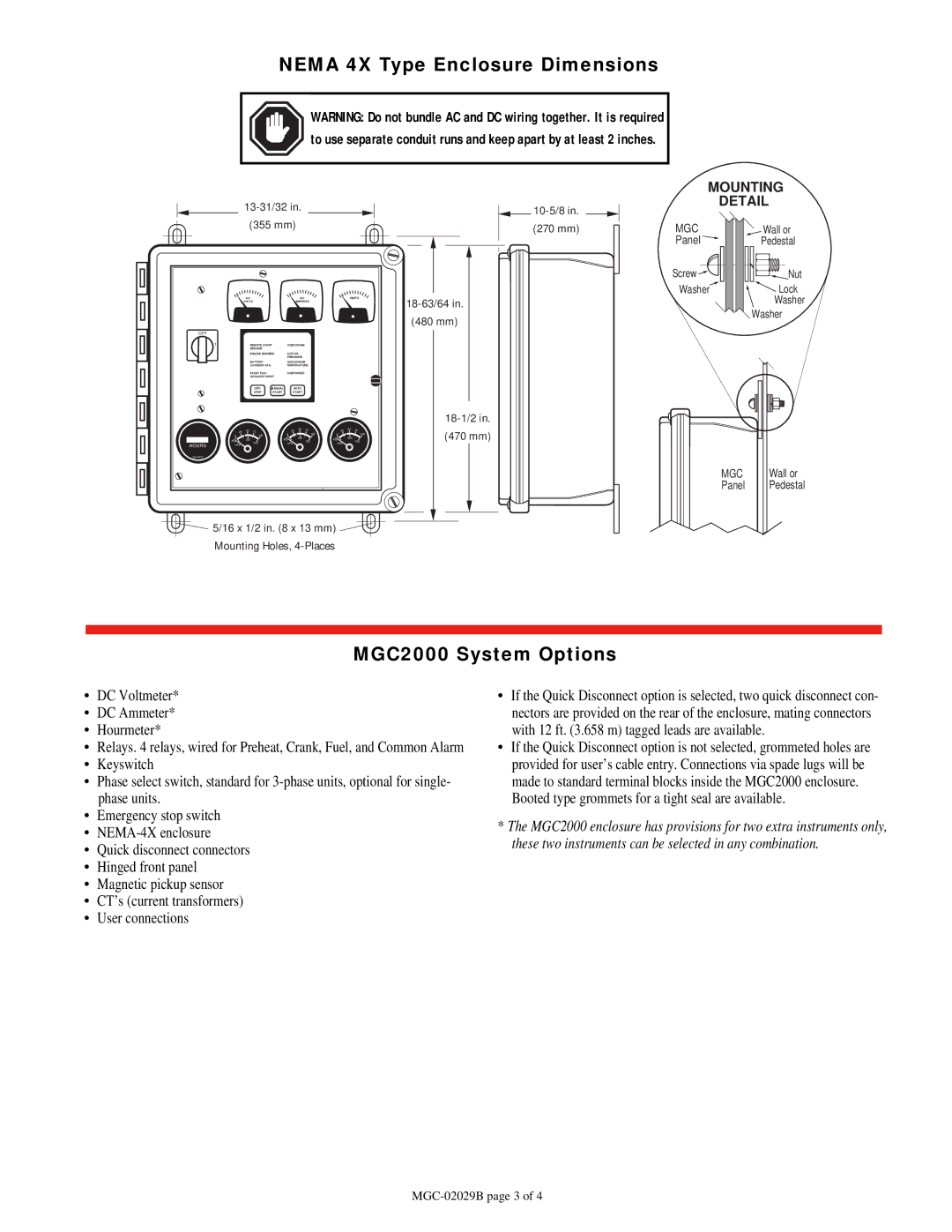

Another essential characteristic of the MGC2000 is its ruggedness, designed to withstand harsh environmental conditions typical in industrial settings. The control system is housed in a durable enclosure that protects it from dust, moisture, and extreme temperatures, ensuring reliable operation regardless of the operational environment.

Additionally, the MGC2000 supports customizable alarm and shutdown settings, providing operators with enhanced control over engine safety and performance. This flexibility allows for tailored solutions that meet specific operational requirements.

With its emphasis on scalability, the MGC2000 can easily be adapted to different sizes of operations, making it suitable for both small facilities and large-scale industrial plants. Its modular architecture allows for easy upgrades and enhancements as technology evolves or organizational needs change.

In summary, the Murphy MGC2000 stands at the forefront of industrial control technology, offering advanced monitoring features, robust communication capabilities, and the flexibility needed to cater to diverse applications. Its reliability and emphasis on predictive maintenance make it an indispensable tool for operators aiming to optimize their engine and generator performance while minimizing risk and operating costs.