Series 1500 specifications

The Murphy Series 1500 is a line of advanced engine monitoring and control solutions designed for a variety of applications, particularly in the industrial and commercial sectors. This series stands out for its combination of robust features, cutting-edge technologies, and reliable characteristics, making it a preferred choice for engine management and performance optimization.One of the main features of the Murphy Series 1500 is its comprehensive monitoring capabilities. Equipped with a range of sensors and gauges, this series provides real-time data on critical engine parameters such as temperature, pressure, and RPM. This data is essential for ensuring optimal engine performance, reducing the risk of failure, and prolonging the life of the engine.

Another significant aspect of the Series 1500 is its user-friendly interface. The display is designed for clarity and ease of use, allowing operators to quickly interpret information and make informed decisions. The intuitive layout ensures that users can navigate through different functions without extensive training, making it suitable for various skill levels.

The Murphy Series 1500 integrates advanced communication technologies, facilitating seamless connectivity with other equipment and supervisory systems. This feature allows for remote monitoring and control, enabling operators to manage engines from a distance, enhancing operational efficiency and safety.

In addition to monitoring and control, the Series 1500 offers customizable alarms and alerts. Users can set specific parameters for engine performance, and the system will notify them if these parameters are exceeded. This proactive approach helps to prevent costly downtime and unexpected maintenance.

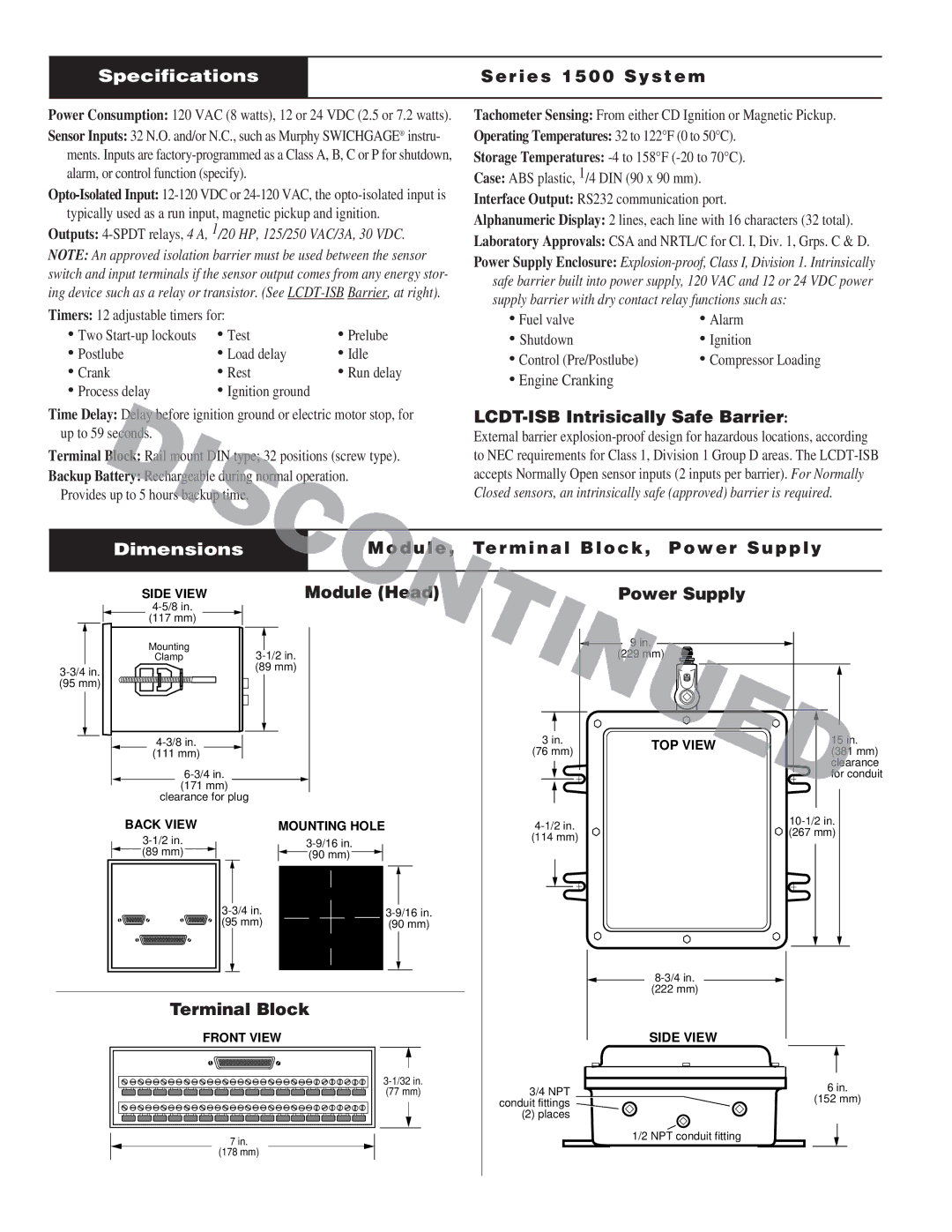

Durability is a hallmark of the Murphy Series 1500. Designed for harsh operating environments, the equipment is constructed with high-quality materials that can withstand extreme temperatures, vibrations, and potential exposure to corrosive elements. This resilience ensures that the system remains functional and reliable in challenging conditions.

Lastly, the Murphy Series 1500 is supported by extensive documentation and customer service. Detailed manuals and troubleshooting guides help users optimize the system's performance while a dedicated support team provides assistance when needed.

In summary, the Murphy Series 1500 is a sophisticated engine management solution that combines monitoring capabilities, user-friendliness, advanced communication technologies, customizable alerts, durability, and robust customer support. These features make it an ideal choice for various industrial applications, ensuring that engines operate efficiently and reliably.