425007x92C specifications

Murray 425007x92C is a versatile and efficient piece of machinery that has garnered attention for its remarkable features and cutting-edge technologies. This model integrates advanced engineering with practical applications, making it a valuable asset in various industries.One of the main features of the Murray 425007x92C is its powerful engine. Designed for optimal performance, this machinery is equipped with a high-capacity powertrain that delivers consistent output even in the most demanding conditions. This not only enhances its operational efficiency but also contributes to reduced overall fuel consumption, which translates to cost savings for users.

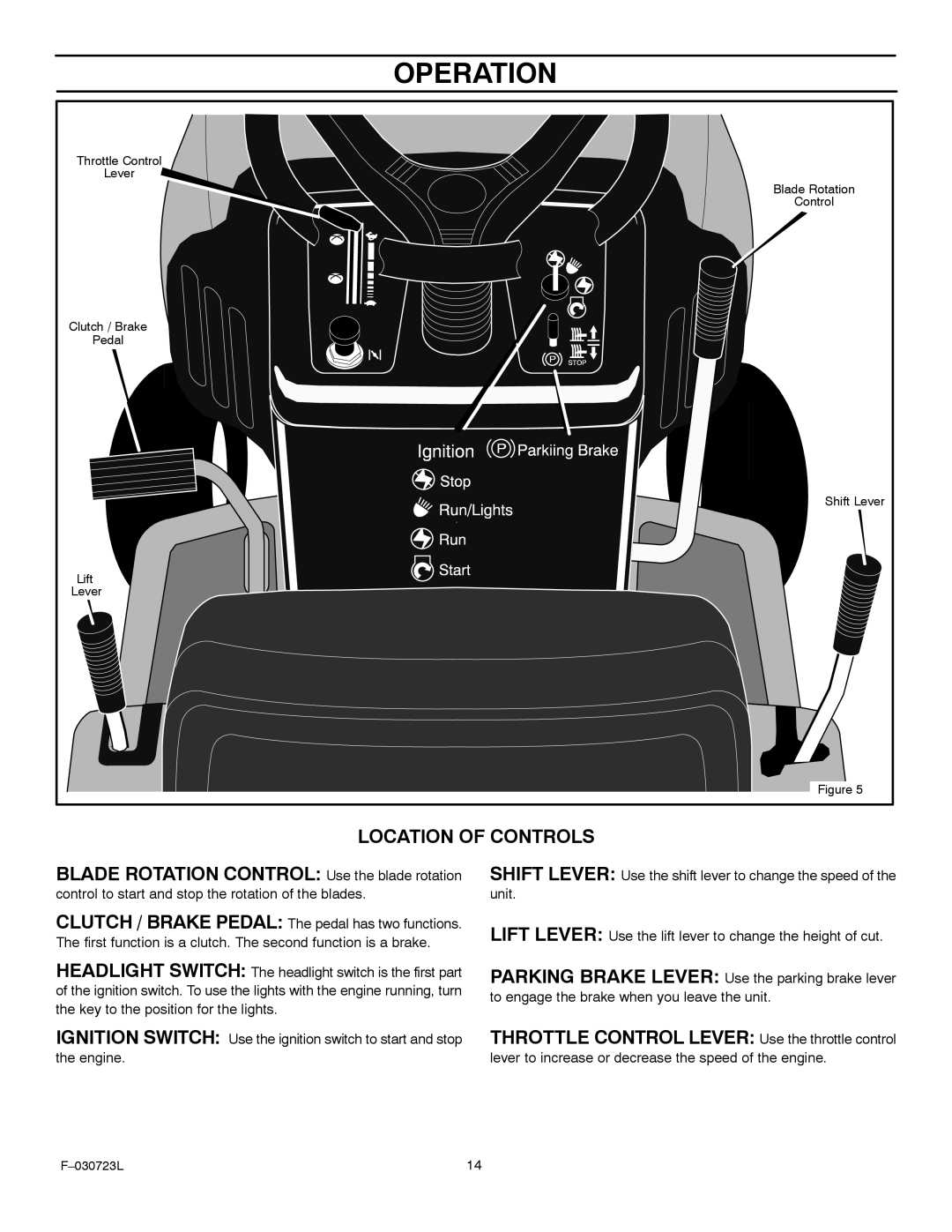

The innovative design of the Murray 425007x92C includes a user-friendly interface that simplifies operation and improves workflow. Operators can easily navigate through controls, with strategically placed buttons and levers that ensure intuitive handling. This focus on usability minimizes the learning curve for new operators, increasing productivity right from the start.

In terms of technology, the Murray 425007x92C incorporates state-of-the-art safety features. These include advanced braking systems and stability controls that provide enhanced safety for operators and bystanders alike. Furthermore, the machinery is equipped with real-time diagnostic tools that monitor its performance and alert users to any potential issues before they escalate. This emphasis on safety and reliability ensures that downtime is minimized.

The construction of the Murray 425007x92C emphasizes durability. Made from high-quality materials, it resists wear and tear and is built to withstand harsh working environments. This robust construction not only enhances its lifespan but also decreases the need for frequent maintenance, making it a cost-effective choice for businesses.

Another distinguishing characteristic of the Murray 425007x92C is its adaptability. It can be easily customized with various attachments that cater to different tasks, ranging from landscaping to heavy construction. This versatility allows operators to switch between applications seamlessly, maximizing productivity and making it an indispensable tool for contractors and maintenance personnel.

Overall, the Murray 425007x92C stands out for its combination of power, safety, durability, and adaptability. Whether used in construction, agricultural, or industrial settings, it proves to be a reliable and efficient solution for various operational needs, reflecting modern engineering excellence.