16

5.Remove nails from the shingles, above and to the sides of the chimney. Place the flashing over the air terminal and slide it underneath the sides and upper edge of the shingles. Ensure that the air terminal is properly centred within the flashing, giving a 3/4" margin all around. Fasten to the roof. Do not nail through the lower portion of the flashing. Make

6.Apply a heavy bead of weatherproof caulking 2 inches above the flashing. Slide the storm collar around the air terminal and down to the

caulking. Tighten to ensure that a

and the collar is achieved.

Attach the other storm 2”![]()

![]() collar centred between the

collar centred between the

air intake vent pipe and the air exhaust slots onto the air terminal. Tighten securely. Attach the vertical rain cap.

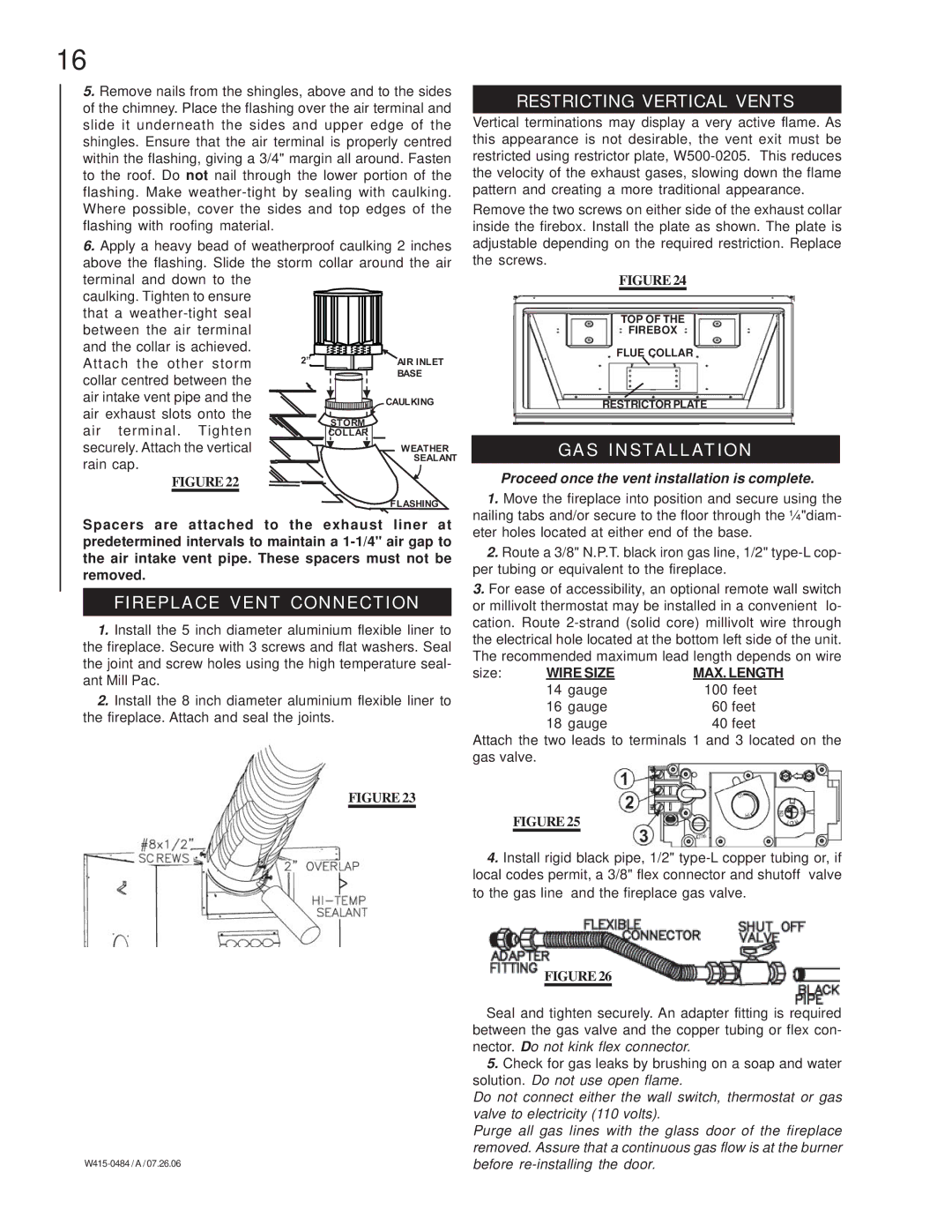

RESTRICTING VERTICAL VENTS

Vertical terminations may display a very active flame. As this appearance is not desirable, the vent exit must be restricted using restrictor plate,

Remove the two screws on either side of the exhaust collar inside the firebox. Install the plate as shown. The plate is adjustable depending on the required restriction. Replace the screws.

FIGURE 24

TOP OF THE

FIREBOX

FLUE COLLAR

RESTRICTOR PLATE

GAS INSTALLATION

Proceed once the vent installation is complete.

1.Move the fireplace into position and secure using the nailing tabs and/or secure to the floor through the ¼"diam- eter holes located at either end of the base.

2.Route a 3/8" N.P.T. black iron gas line, 1/2"

3.For ease of accessibility, an optional remote wall switch or millivolt thermostat may be installed in a convenient lo- cation. Route

size: | WIRE SIZE | MAX. LENGTH | |

| 14 | gauge | 100 feet |

| 16 | gauge | 60 feet |

| 18 | gauge | 40 feet |

Attach the two leads to terminals 1 and 3 located on the gas valve.

FIGURE 25

4.Install rigid black pipe, 1/2"

FIGURE 26

Seal and tighten securely. An adapter fitting is required between the gas valve and the copper tubing or flex con- nector. Do not kink flex connector.

5.Check for gas leaks by brushing on a soap and water solution. Do not use open flame.

Do not connect either the wall switch, thermostat or gas valve to electricity (110 volts).

Purge all gas lines with the glass door of the fireplace removed. Assure that a continuous gas flow is at the burner before