HYDRAULIC SYSTEM

Hydraulic Productivity

The more demanding your application, the greater the need to properly manage the tractor hydraulic system. Proper circuit connection, use of the flow control, and removal of unintended circuit restrictions can improve hydraulic system performance.

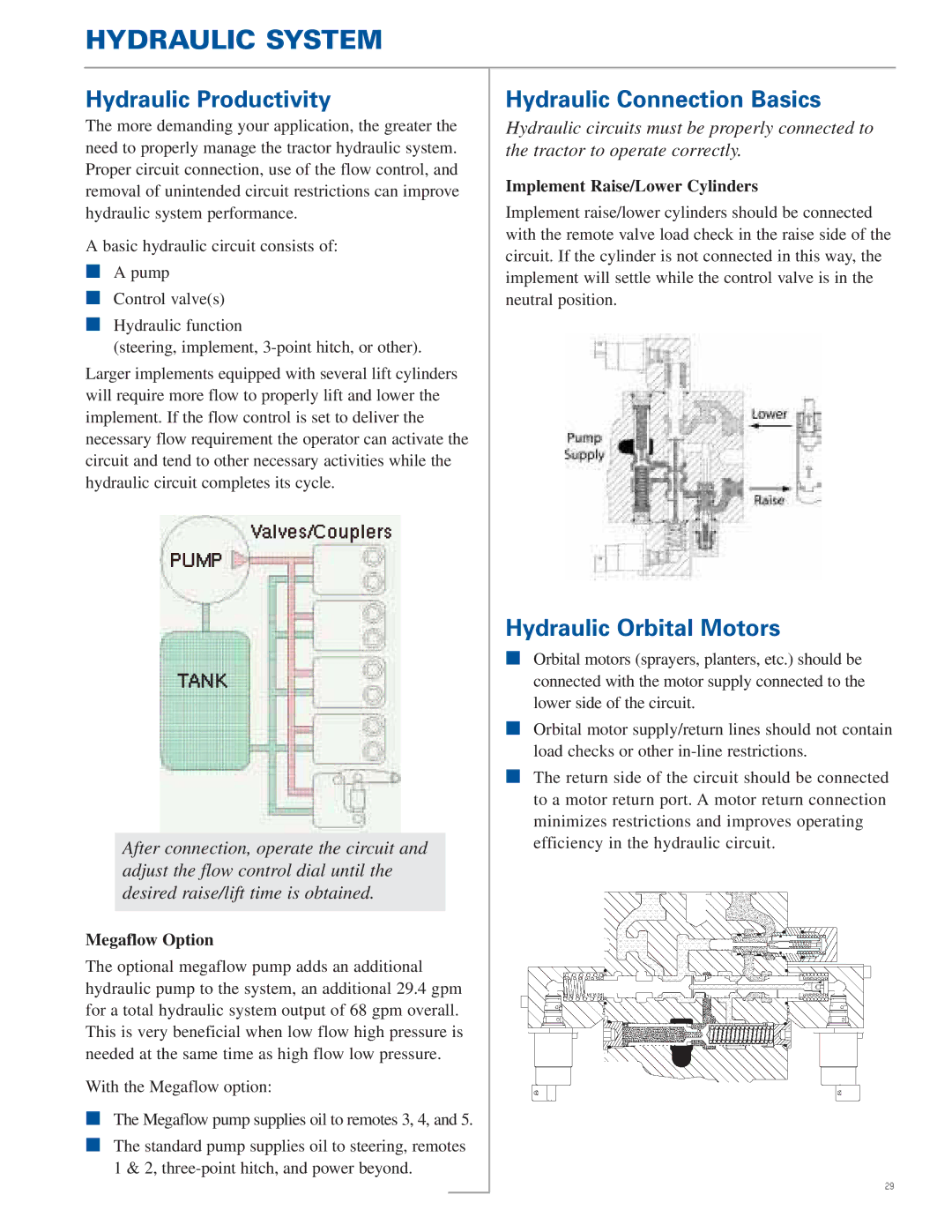

A basic hydraulic circuit consists of:

Apump Control valve(s)

Hydraulic function

(steering, implement,

Larger implements equipped with several lift cylinders will require more flow to properly lift and lower the implement. If the flow control is set to deliver the necessary flow requirement the operator can activate the circuit and tend to other necessary activities while the hydraulic circuit completes its cycle.

After connection, operate the circuit and adjust the flow control dial until the desired raise/lift time is obtained.

Megaflow Option

The optional megaflow pump adds an additional hydraulic pump to the system, an additional 29.4 gpm for a total hydraulic system output of 68 gpm overall. This is very beneficial when low flow high pressure is needed at the same time as high flow low pressure.

With the Megaflow option:

The Megaflow pump supplies oil to remotes 3, 4, and 5.

The standard pump supplies oil to steering, remotes 1 & 2,

Hydraulic Connection Basics

Hydraulic circuits must be properly connected to the tractor to operate correctly.

Implement Raise/Lower Cylinders

Implement raise/lower cylinders should be connected with the remote valve load check in the raise side of the circuit. If the cylinder is not connected in this way, the implement will settle while the control valve is in the neutral position.

Hydraulic Orbital Motors

Orbital motors (sprayers, planters, etc.) should be connected with the motor supply connected to the lower side of the circuit.

Orbital motor supply/return lines should not contain load checks or other

The return side of the circuit should be connected to a motor return port. A motor return connection minimizes restrictions and improves operating efficiency in the hydraulic circuit.