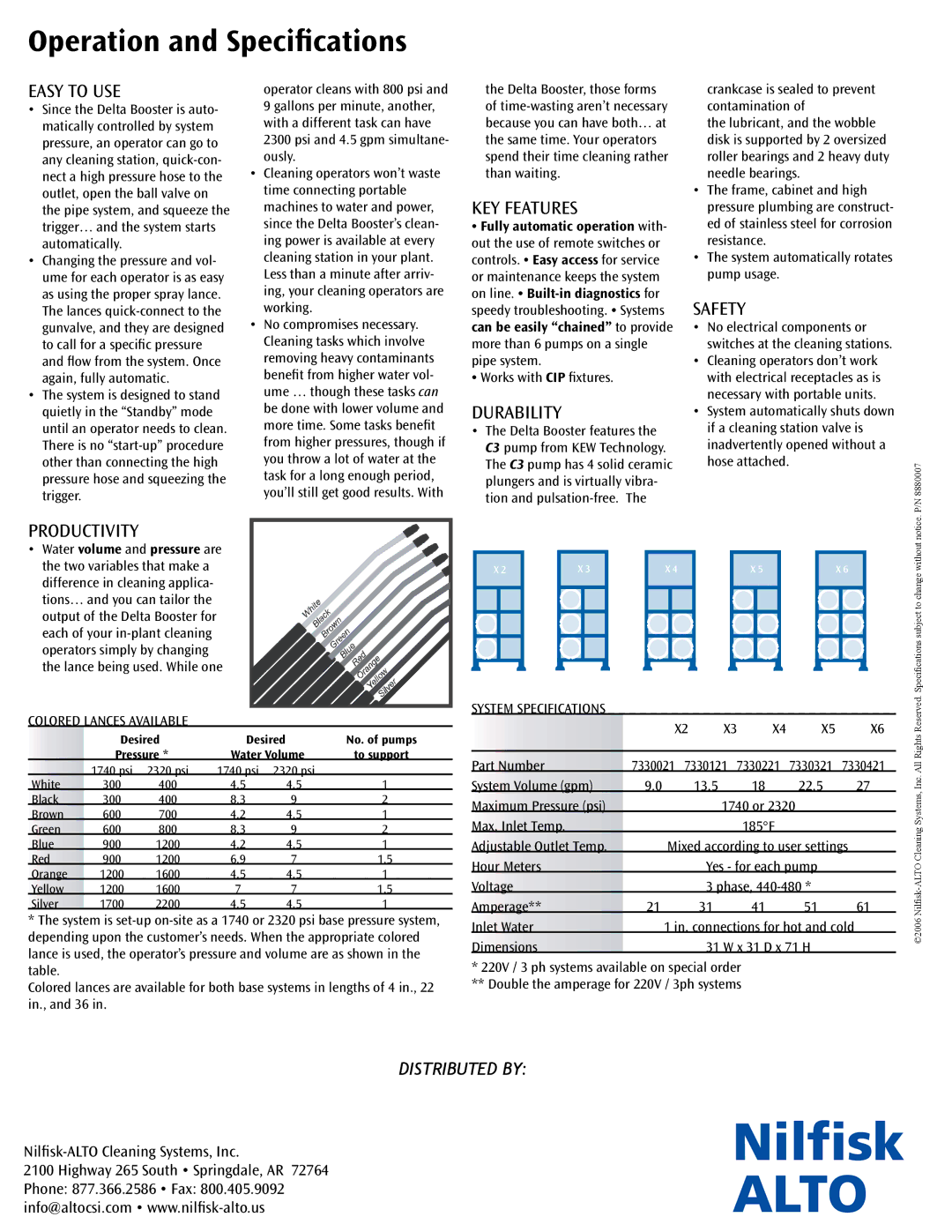

Multi-User Pressure Washer System specifications

The Nilfisk-ALTO Multi-User Pressure Washer System stands out as a premier solution for a wide range of cleaning tasks, combining powerful cleaning capabilities with innovative technologies designed for efficiency and ease of use. This system is especially ideal for commercial applications, where multiple users may need access to high-pressure cleaning solutions simultaneously.One of the main features of the Nilfisk-ALTO system is its ability to support multiple users. This multi-user functionality allows up to four operators to use the system at the same time, significantly enhancing productivity in environments such as facilities management, construction sites, and industrial maintenance. Each user can work independently without waiting for their turn, streamlining operations and reducing downtime.

The system is equipped with a robust high-pressure pump that delivers outstanding performance, offering pressure levels that are adjustable to suit various cleaning tasks. This versatility means that whether you are cleaning delicate surfaces or dealing with heavy-duty grime, the Nilfisk-ALTO can effectively handle the job. Additionally, the system's flow rate capabilities ensure that users can complete their tasks quickly and efficiently.

An important characteristic of the Nilfisk-ALTO Multi-User Pressure Washer is its user-friendly design. The intuitive controls allow for easy operation, even for those who may not be familiar with high-pressure cleaning equipment. Moreover, it features a durable construction, built to withstand the rigors of frequent use in demanding environments. The robust chassis and components contribute to the long lifespan of the system, making it a cost-effective investment over time.

Technology plays a significant role in the performance of the Nilfisk-ALTO system. It incorporates advanced features such as automatic shut-off, which enhances safety by turning off the pump when not in use. This feature not only prolongs the life of the pump but also conserves energy. Furthermore, the system is designed to minimize noise levels, making it suitable for use in noise-sensitive areas while ensuring compliance with local regulations.

Incorporating flexible hose options and a range of attachments, the Nilfisk-ALTO Multi-User Pressure Washer System is adaptable to various cleaning scenarios. The quick coupling system allows operators to switch between different nozzles and accessories effortlessly. Whether it’s for surface cleaning, sanitation, or degreasing, the Nilfisk-ALTO provides a comprehensive solution that meets diverse cleaning needs.

Ultimately, the Nilfisk-ALTO Multi-User Pressure Washer System is a forward-thinking cleaning solution that prioritizes efficiency, power, and versatility, making it a valuable tool for any organization focused on maintaining cleanliness and hygiene.