OPERATION

1.Before making the connection to the electric control panel, check that the line voltage corresponds to that shown on the motor plate. In case of

2.The user must provide the electrical connection to the hoist using insulated conductors of adequate

3.The

4.At the time of installation, check so that when the hook descends to the endpoint of its travel, at least three turns of rope remain wound on the drum. The rope must never be unwound further that this. The unwinding limit is shown on the rope by a red mark.

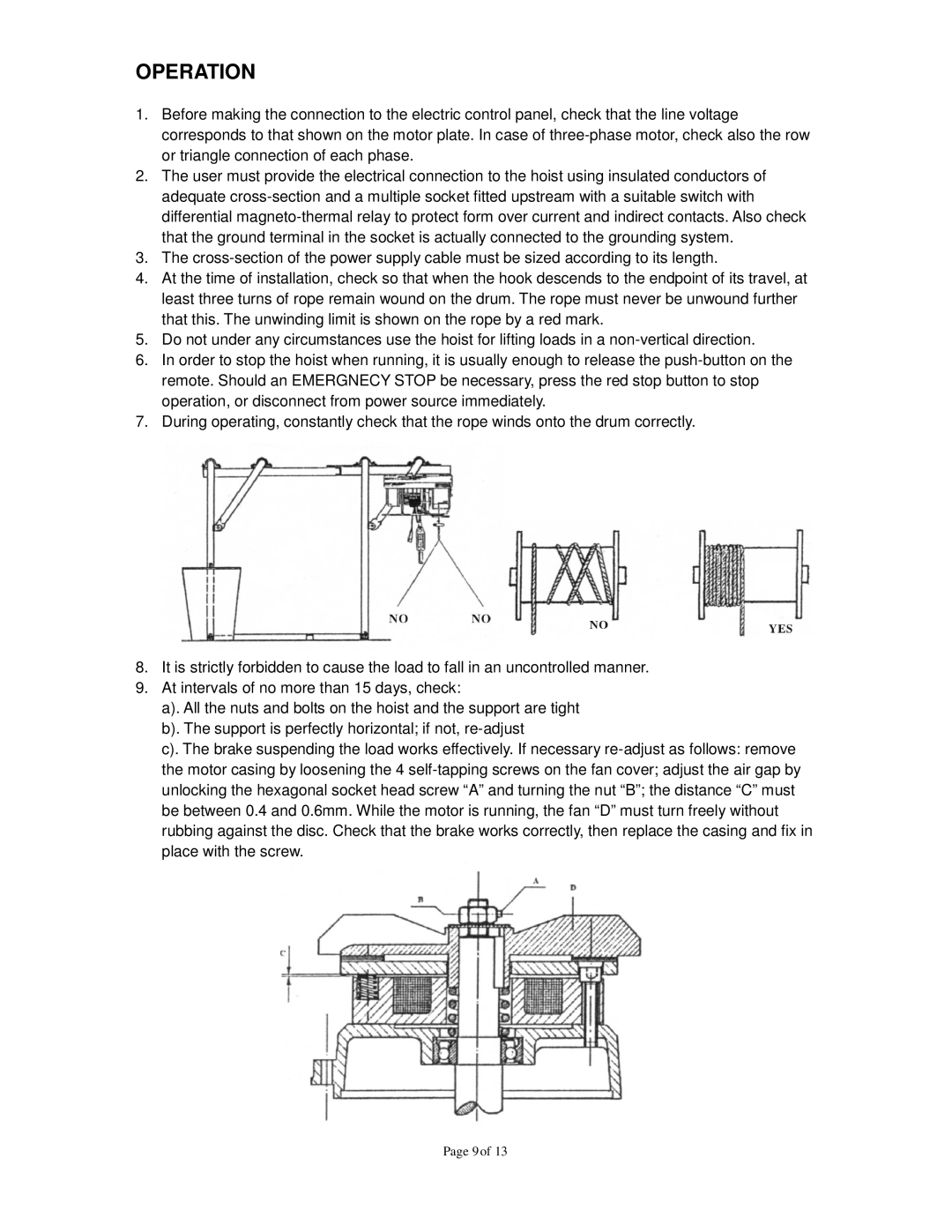

5.Do not under any circumstances use the hoist for lifting loads in a

6.In order to stop the hoist when running, it is usually enough to release the

7.During operating, constantly check that the rope winds onto the drum correctly.

8.It is strictly forbidden to cause the load to fall in an uncontrolled manner.

9.At intervals of no more than 15 days, check:

a). All the nuts and bolts on the hoist and the support are tight b). The support is perfectly horizontal; if not,

c). The brake suspending the load works effectively. If necessary

Page 9 of 13