Cut-Off Wheels For Metal Fabrication specifications

Norton Abrasives has long been a trusted name in the metal fabrication industry, particularly known for its high-quality cut-off wheels. These wheels are essential tools designed to slice through various types of metal with precision and efficiency, making them invaluable in workshops and job sites alike. With advancements in technology and materials, Norton continues to set the standard in cut-off wheel performance.One of the main features of Norton cut-off wheels is their durable construction. Made with premium quality abrasive grains, these wheels provide a long lifespan and consistent cutting performance. The design minimizes wear and tear, ensuring that users get the most out of each wheel. This durability is particularly crucial in metal fabrication, where frequent and aggressive cutting can quickly wear down inferior products.

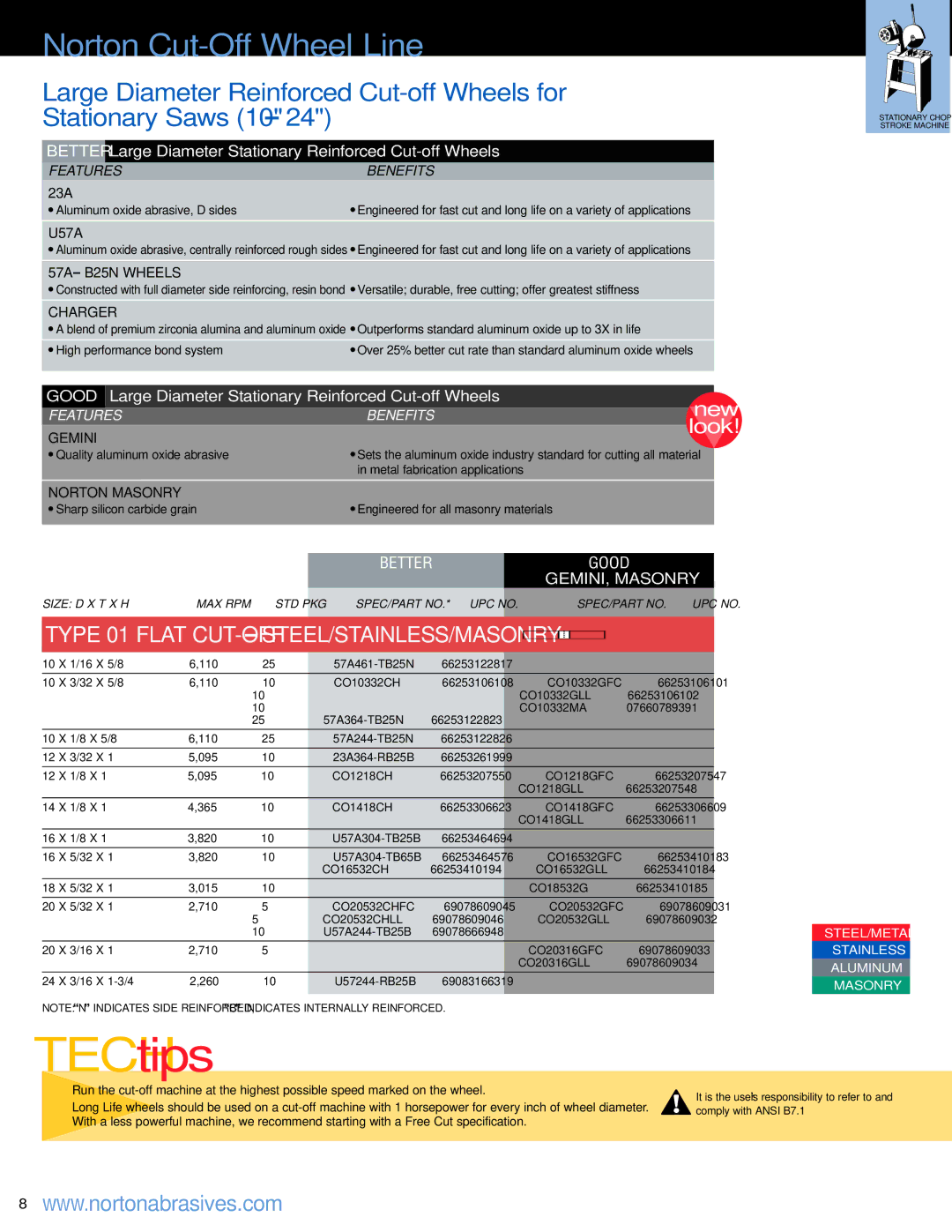

Another notable characteristic of Norton cut-off wheels is their versatility. They are designed to work effectively on a multitude of metals, including stainless steel, aluminum, and carbon steel. This adaptability is further enhanced by the extensive range of wheel sizes and thicknesses that Norton offers, allowing users to select the most appropriate wheel for their specific applications.

Norton has also integrated advanced technology into their cut-off wheels. One such innovation is the incorporation of proprietary bond systems that enhance the wheel's stability and performance under high stress. These bonds help in maintaining the integrity of the wheel during operation, reducing the risk of breakage and ensuring safe usage.

Additionally, the company emphasizes safety in their product designs. Norton cut-off wheels are rigorously tested and manufactured to meet stringent safety standards. Features such as reinforced backing plates and a consistent formulation help to prevent cracks and premature wear, providing peace of mind to operators.

Furthermore, Norton cut-off wheels are engineered for efficiency. This efficiency translates into faster cutting speeds and reduced friction, which not only saves time but also minimizes heat buildup during operation. This characteristic is particularly beneficial in preventing warping or damaging the materials being cut.

In summary, Norton Abrasives cut-off wheels stand out in the metal fabrication industry due to their durable construction, versatility, advanced technology, and commitment to safety. These wheels are designed to meet the demands of professionals, making them an essential component in any metalworking toolkit. Whether for cutting, grinding, or finishing, Norton offers the right cut-off wheel to enhance productivity and ensure high-quality results in metal fabrication projects.