2. INITIAL SETUP

The

1.Mount the power supply in a convenient location in your workspace, such as on the workbench.

2.Insert a heater tip onto the Coil Assembly and simply push the Heater Tip all the way until it seats. You should feel a slight “click” as it locks into place.

Insert Tip onto Coil Assembly

3.With the power “Off”, attach the solder handle cord to the power supply by inserting the cord connector into the power supply connecting port. To align the 3 pins, position the flat side of the cable connector toward the 9 o'clock position of the power supply.

4.Wet the sponge with

5.Plug the power cord into a grounded wall socket of the appropriately rated input line voltage. To turn the unit on, push the switch (located on the front of the power supply) until it latches. The green indicator light should light up. If it does not, see the “Troubleshooting Guide” in this manual.

CAUTION: To provide continued protection against the risk of electric shock, connect only to properly grounded outlets.

3. SMARTHEAT®: NO CALIBRATION REQUIRED

The

2

www.okinternational.com

4. SELECTING HEATER TIPS

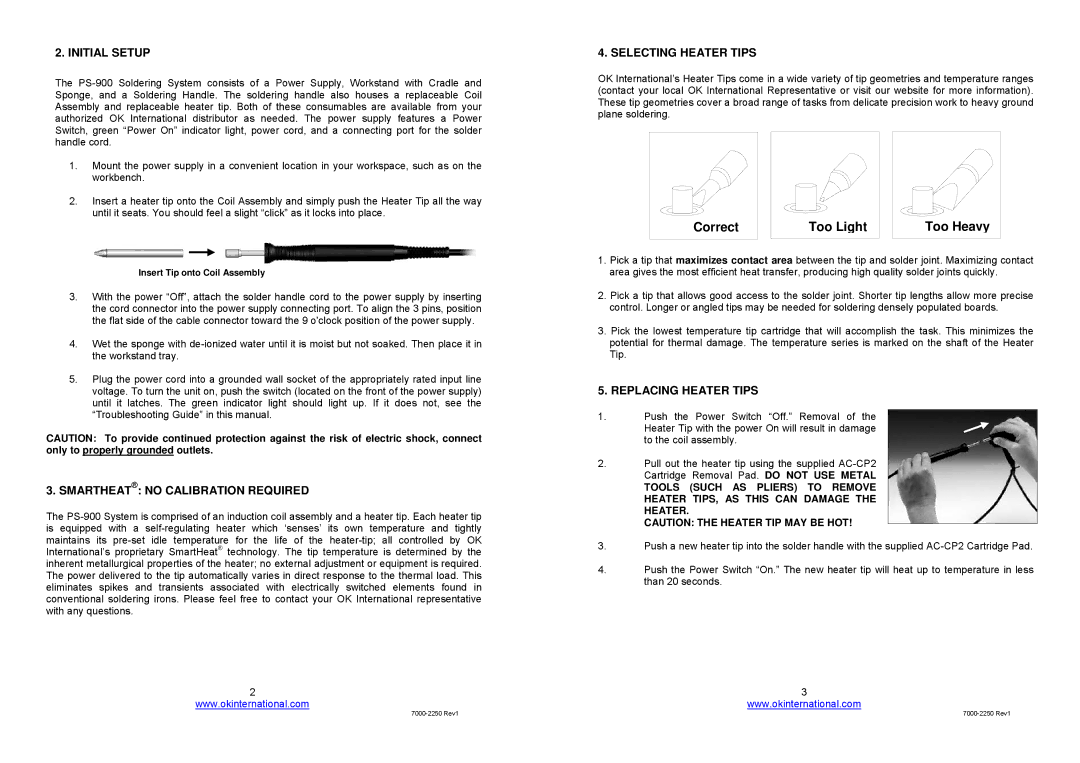

OK International’s Heater Tips come in a wide variety of tip geometries and temperature ranges (contact your local OK International Representative or visit our website for more information). These tip geometries cover a broad range of tasks from delicate precision work to heavy ground plane soldering.

Correct | Too Light | Too Heavy |

1.Pick a tip that maximizes contact area between the tip and solder joint. Maximizing contact area gives the most efficient heat transfer, producing high quality solder joints quickly.

2.Pick a tip that allows good access to the solder joint. Shorter tip lengths allow more precise control. Longer or angled tips may be needed for soldering densely populated boards.

3.Pick the lowest temperature tip cartridge that will accomplish the task. This minimizes the potential for thermal damage. The temperature series is marked on the shaft of the Heater Tip.

5. REPLACING HEATER TIPS

1.Push the Power Switch “Off.” Removal of the

Heater Tip with the power On will result in damage to the coil assembly.

2.Pull out the heater tip using the supplied

TOOLS (SUCH AS PLIERS) TO REMOVE HEATER TIPS, AS THIS CAN DAMAGE THE HEATER.

CAUTION: THE HEATER TIP MAY BE HOT!

3.Push a new heater tip into the solder handle with the supplied

4.Push the Power Switch “On.” The new heater tip will heat up to temperature in less than 20 seconds.

3

www.okinternational.com