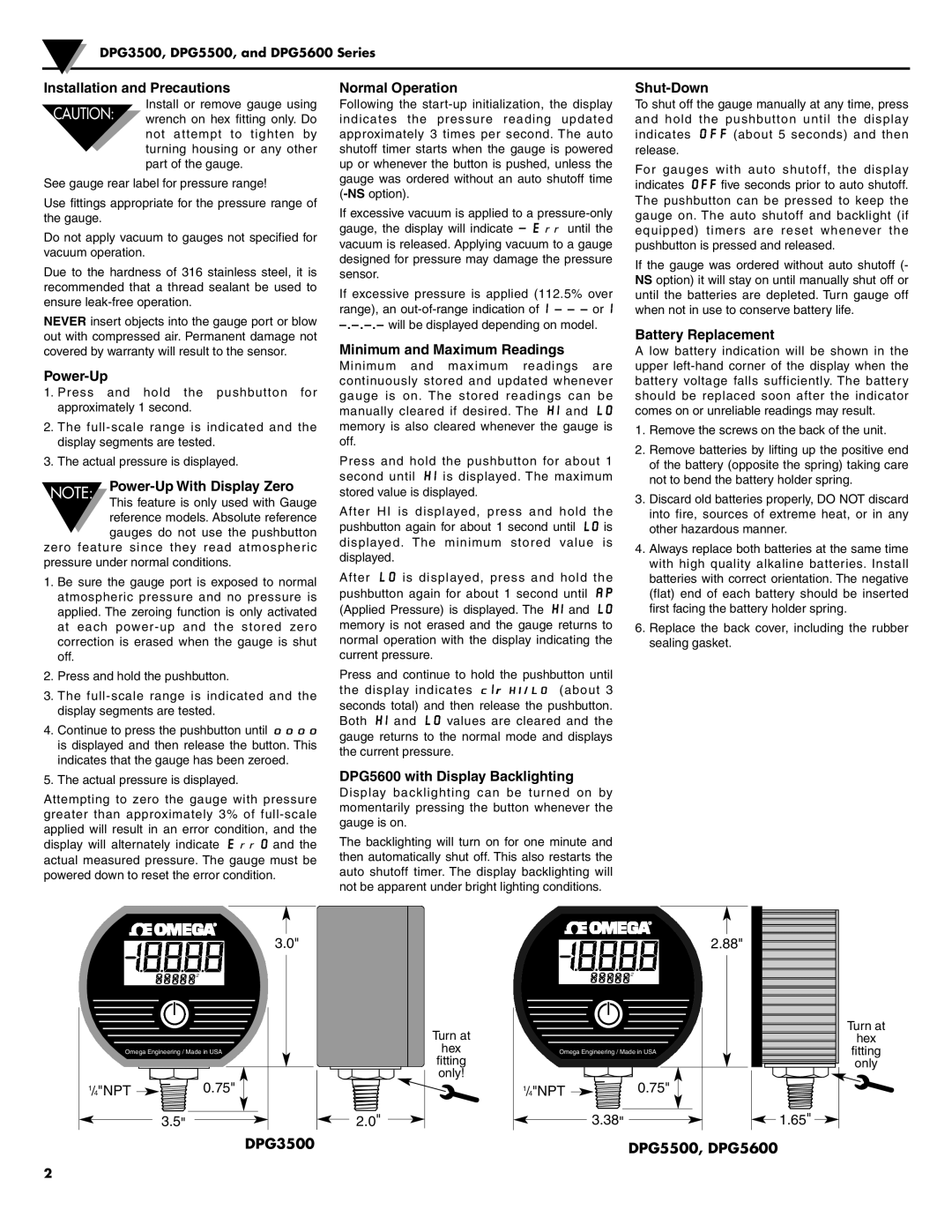

DPG5500, DPG3500, DPG5600 specifications

The Omega DPG3500, DPG5600, and DPG5500 are advanced digital pressure gauges known for their accuracy, durability, and user-friendly interfaces. These instruments are designed to provide precise pressure measurements in various industrial applications, making them essential tools for engineers and technicians.The DPG3500 is equipped with a high-resolution display that offers clear readings, making it easy to monitor pressure in real time. It features a robust housing that ensures resistance to harsh environmental conditions, such as dust and moisture, making it suitable for field use. The gauge is designed with a precision sensor that guarantees excellent linearity and repeatability, which are critical for accurate measurements.

In contrast, the DPG5600 incorporates more advanced features, such as an enhanced data logging capability. This allows users to record measurements over time, facilitating trend analysis and troubleshooting in processes where pressure fluctuations may indicate potential issues. The DPG5600 also supports multiple pressure units, catering to various user preferences and industry standards. The intuitive menu navigation makes setting up and configuring the gauge quick and straightforward, ensuring minimal downtime when switching tasks.

The DPG5500 stands out with its integrated Bluetooth connectivity, enabling users to wirelessly transmit data to smartphones or computers. This feature allows for real-time monitoring and easy sharing of data among team members. Additionally, the DPG5500 boasts a rechargeable battery, providing extended operational life without the hassle of frequent battery replacements. The LCD display presents not only the pressure reading but also important status indicators, such as battery level and connectivity status.

All three models utilize cutting-edge sensor technologies, ensuring high accuracy across a wide range of pressures. They are engineered to handle dynamic pressures, making them ideal for use in systems with rapidly changing pressure levels. The gauges also offer various customization options, including programmable set points, alarms, and differential pressure measurement capabilities.

In summary, the Omega DPG3500, DPG5600, and DPG5500 are versatile digital pressure gauges that cater to diverse industrial needs. Each model combines advanced technologies, robust construction, and user-centric features, making them reliable choices for professionals who require precise and consistent pressure measurements. Whether for basic monitoring or complex data analysis, these gauges enhance operational efficiency and facilitate informed decision-making in various industrial environments.