CAUTION: Calibration Precautions

Install or remove gauge using wrench on hex fitting only. Do not attempt to tighten or loosen by turning housing or any other part of the gauge.

See gauge rear label for pressure range!

Use fittings appropriate for the pressure range of the gauge. The gauge range is indicated on the rear label and is indicated on the display during power-up.

Do not apply vacuum to gauges not designed for vacuum operation.

Due to the hardness of 316 stainless steel, it is recommended that a thread sealant be used to ensure leak-free operation.

NEVER insert objects into the gauge port or blow out with compressed air. Permanent damage not covered by warranty will result to the sensor.

These products do not contain user serviceable parts. Contact Omega Engineering for calibration, service, or refurbishment.

NOTE:

1.Calibration Preparation

a.Calibration should only be performed by qualified individuals using appropriate calibration standards and procedures.

b.The calibration equipment should be at least four times more accurate than the gauge being calibrated.

c.Remove the screws on the back of the unit and remove cover.

d.It is good practice to install fresh batteries before calibrating battery- powered gauges.

e.Allow the gauge to equalize to normal room temperature before calibration.

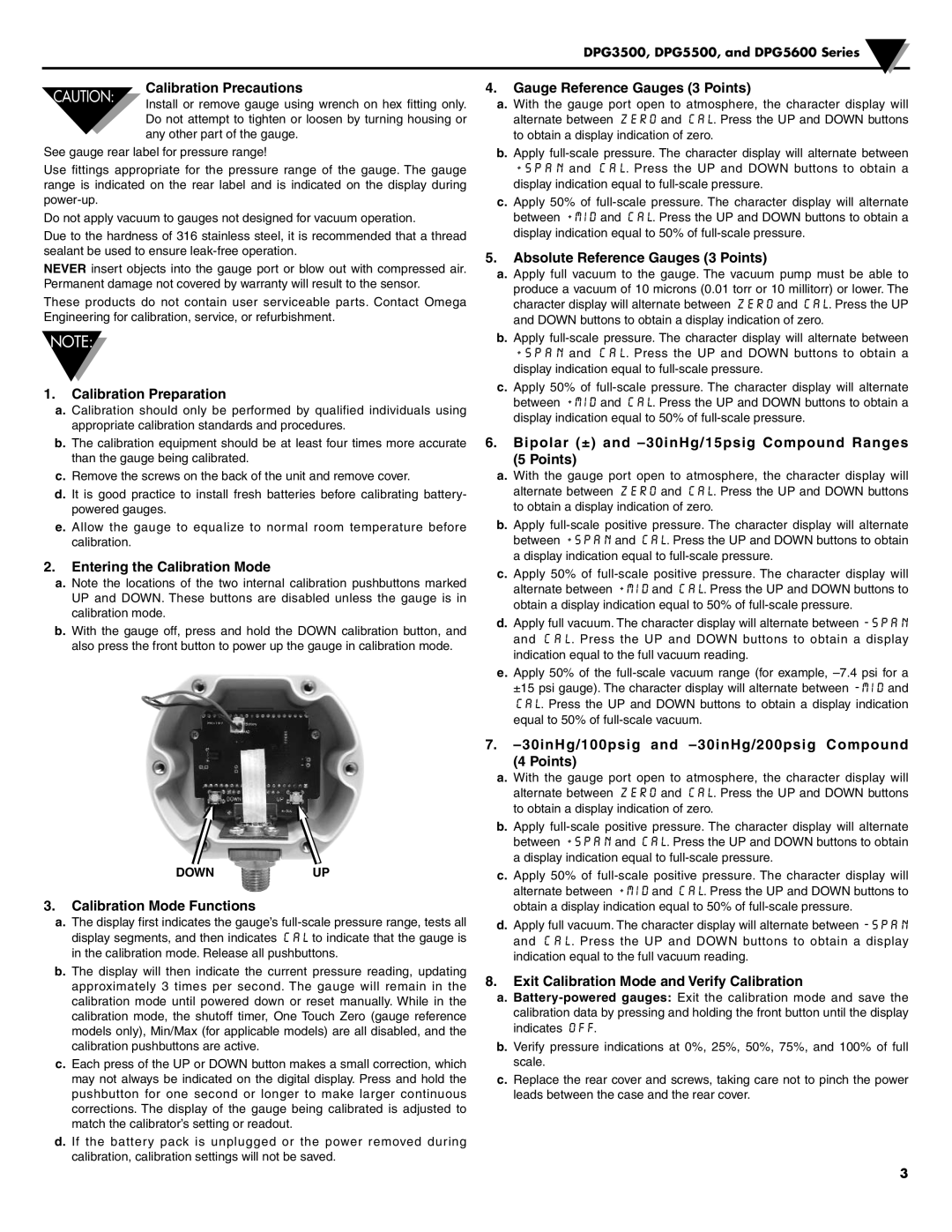

2.Entering the Calibration Mode

a.Note the locations of the two internal calibration pushbuttons marked UP and DOWN. These buttons are disabled unless the gauge is in calibration mode.

b.With the gauge off, press and hold the DOWN calibration button, and also press the front button to power up the gauge in calibration mode.

DOWNUP

3.Calibration Mode Functions

a.The display first indicates the gauge’s full-scale pressure range, tests all display segments, and then indicates CAL to indicate that the gauge is in the calibration mode. Release all pushbuttons.

b.The display will then indicate the current pressure reading, updating approximately 3 times per second. The gauge will remain in the calibration mode until powered down or reset manually. While in the calibration mode, the shutoff timer, One Touch Zero (gauge reference models only), Min/Max (for applicable models) are all disabled, and the calibration pushbuttons are active.

c.Each press of the UP or DOWN button makes a small correction, which may not always be indicated on the digital display. Press and hold the pushbutton for one second or longer to make larger continuous corrections. The display of the gauge being calibrated is adjusted to match the calibrator’s setting or readout.

d.If the battery pack is unplugged or the power removed during calibration, calibration settings will not be saved.

4.Gauge Reference Gauges (3 Points)

a.With the gauge port open to atmosphere, the character display will alternate between ZERO and CAL. Press the UP and DOWN buttons to obtain a display indication of zero.

b.Apply full-scale pressure. The character display will alternate between +SPAN and CAL. Press the UP and DOWN buttons to obtain a display indication equal to full-scale pressure.

c.Apply 50% of full-scale pressure. The character display will alternate between +MID and CAL. Press the UP and DOWN buttons to obtain a display indication equal to 50% of full-scale pressure.

5.Absolute Reference Gauges (3 Points)

a.Apply full vacuum to the gauge. The vacuum pump must be able to produce a vacuum of 10 microns (0.01 torr or 10 millitorr) or lower. The character display will alternate between ZERO and CAL. Press the UP and DOWN buttons to obtain a display indication of zero.

b.Apply full-scale pressure. The character display will alternate between +SPAN and CAL. Press the UP and DOWN buttons to obtain a display indication equal to full-scale pressure.

c.Apply 50% of full-scale pressure. The character display will alternate between +MID and CAL. Press the UP and DOWN buttons to obtain a display indication equal to 50% of full-scale pressure.

6.Bipolar (±) and –30inHg/15psig Compound Ranges (5 Points)

a.With the gauge port open to atmosphere, the character display will alternate between ZERO and CAL. Press the UP and DOWN buttons to obtain a display indication of zero.

b.Apply full-scale positive pressure. The character display will alternate between +SPAN and CAL. Press the UP and DOWN buttons to obtain a display indication equal to full-scale pressure.

c.Apply 50% of full-scale positive pressure. The character display will alternate between +MID and CAL. Press the UP and DOWN buttons to obtain a display indication equal to 50% of full-scale pressure.

d.Apply full vacuum. The character display will alternate between -SPAN and CAL. Press the UP and DOWN buttons to obtain a display indication equal to the full vacuum reading.

e.Apply 50% of the full-scale vacuum range (for example, –7.4 psi for a ±15 psi gauge). The character display will alternate between -MID and CAL. Press the UP and DOWN buttons to obtain a display indication equal to 50% of full-scale vacuum.

7.–30inHg/100psig and –30inHg/200psig Compound (4 Points)

a.With the gauge port open to atmosphere, the character display will alternate between ZERO and CAL. Press the UP and DOWN buttons to obtain a display indication of zero.

b.Apply full-scale positive pressure. The character display will alternate between +SPAN and CAL. Press the UP and DOWN buttons to obtain a display indication equal to full-scale pressure.

c.Apply 50% of full-scale positive pressure. The character display will alternate between +MID and CAL. Press the UP and DOWN buttons to obtain a display indication equal to 50% of full-scale pressure.

d.Apply full vacuum. The character display will alternate between -SPAN and CAL. Press the UP and DOWN buttons to obtain a display indication equal to the full vacuum reading.

8.Exit Calibration Mode and Verify Calibration

a.Battery-powered gauges: Exit the calibration mode and save the calibration data by pressing and holding the front button until the display indicates OFF.

b.Verify pressure indications at 0%, 25%, 50%, 75%, and 100% of full scale.

c.Replace the rear cover and screws, taking care not to pinch the power leads between the case and the rear cover.