Page 2

CAUTION

FOLLOW INSTRUCTIONS TO AVOID FAILURE

1.Finish piping to be plumb and true.

2.Polysulfone and other exotic plastics cannot tolerate P.V.C. glue and pipe dope. Even the fumes can cause crazing.

3.Use teflon tape for threaded joints.

4.Make up assembly and fit pipes, then: remove F.M. after glue fumes are vented out.

5.Meter cannot support attached pipes.

6.Excessive vibration may cause float to give poor reading or cause possible fracture.

7.Wall, floor, and ceiling mounts to be carefully aligned and sturdy. A support should be at top and bottom of meter. See drawing.

8.Hand tighten union nuts. No wrenches.

9.Protect meter from ultra violet (UV) rays.

10.VALVES - avoid system that will impose a sudden burst of flow to the meter. Such a burst will cause the float to impact the guide assembly with destructive force. Magnet, solenoid, or other quick opening valves cannot be used unless meter is protected against sudden burst of flow.

11.Failure to comply VOIDS WARRANTY!

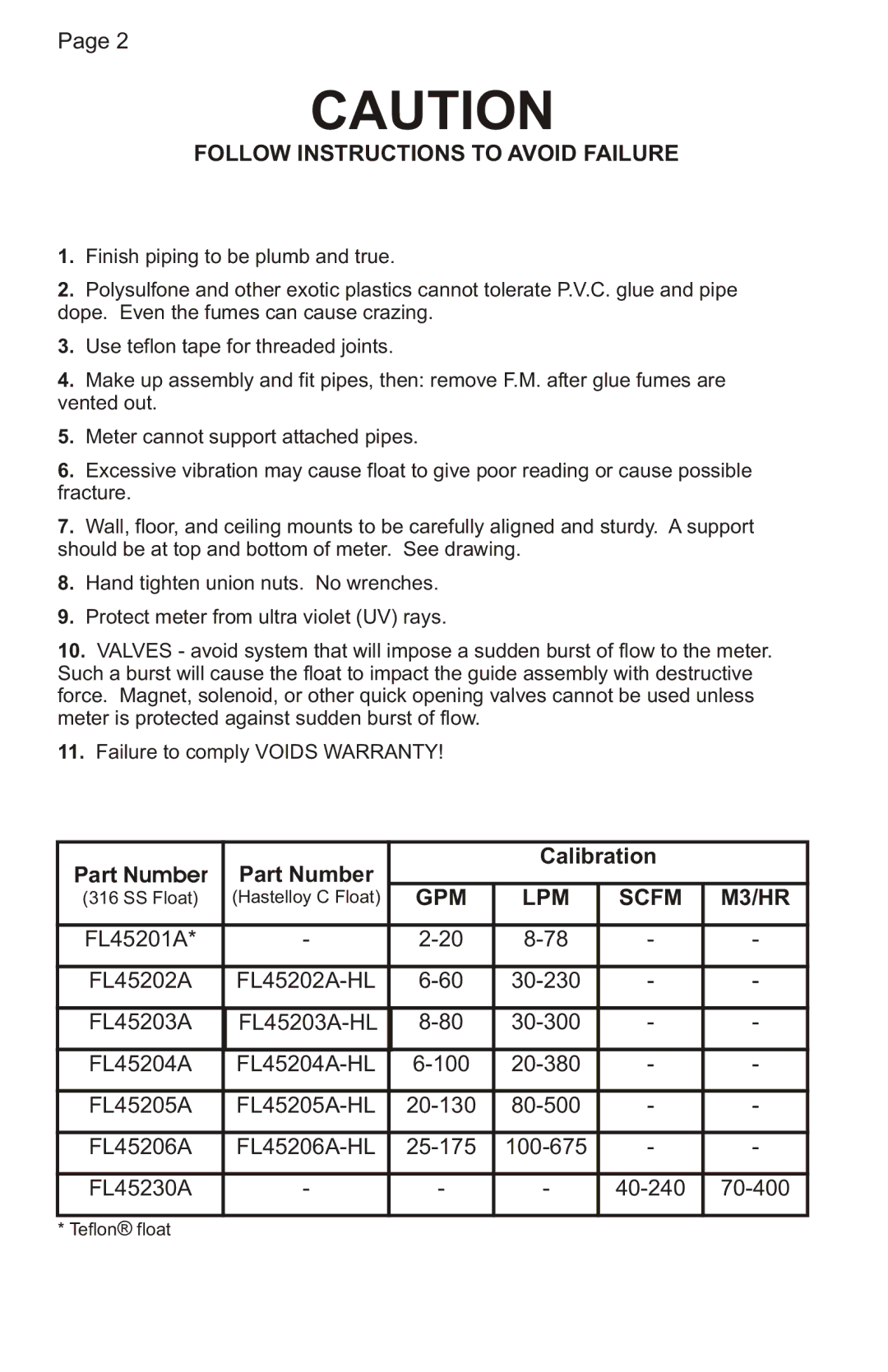

Part Number | Part Number |

| Calibration |

| |

|

|

|

| ||

(316 SS Float) | (Hastelloy C Float) | GPM | LPM | SCFM | M3/HR |

|

|

|

|

|

|

FL45201A* | - | - | - | ||

|

|

|

|

|

|

FL45202A | - | - | |||

|

|

|

|

|

|

FL45203A | - | - | |||

|

|

|

|

|

|

FL45204A | - | - | |||

|

|

|

|

|

|

FL45205A | - | - | |||

|

|

|

|

|

|

FL45206A | - | - | |||

|

|

|

|

|

|

FL45230A | - | - | - | ||

|

|

|

|

|

|

* Teflon® float