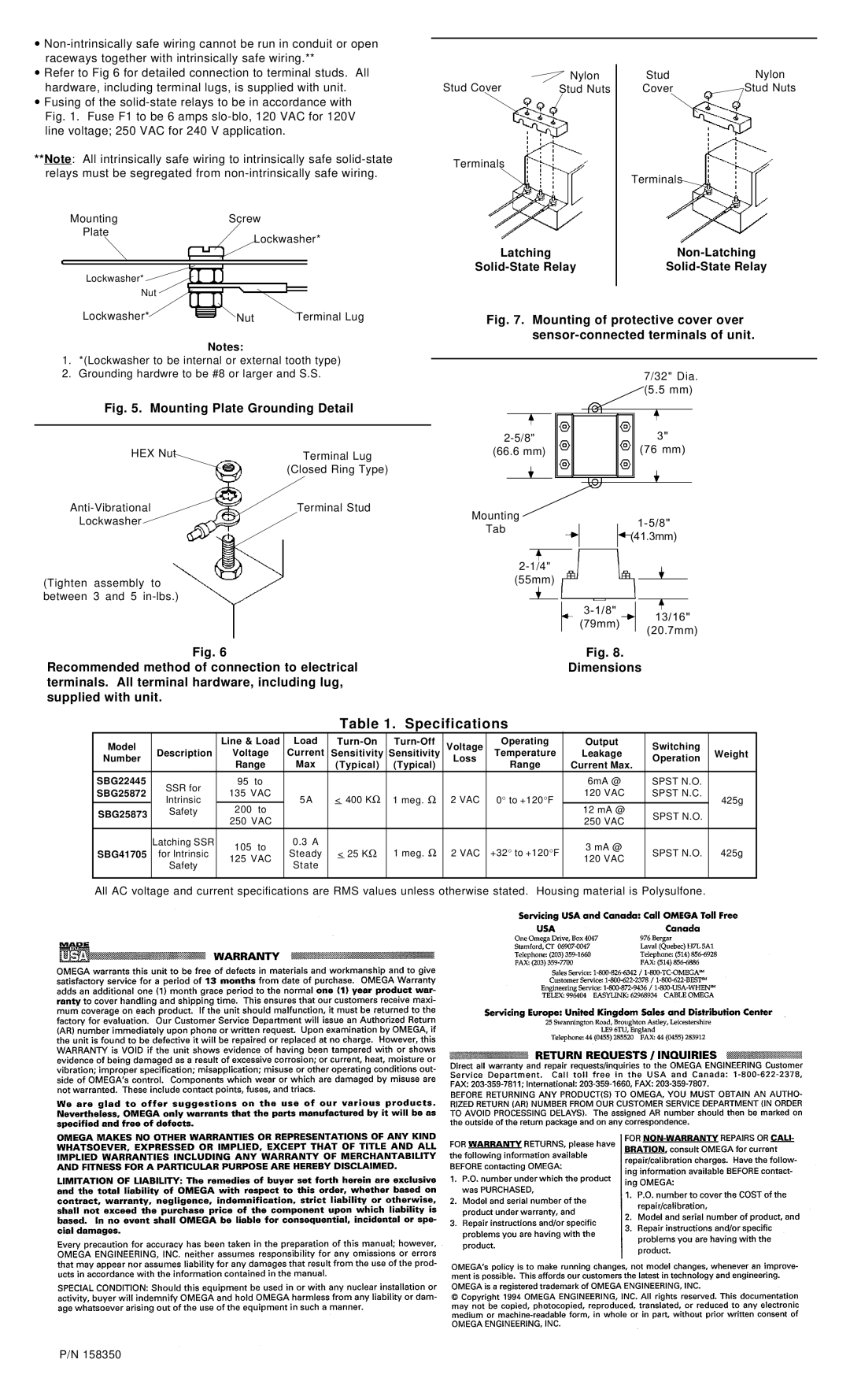

SBG25873, SBG41705, SBG25872, SBG22445 specifications

Omega Engineering is a well-known name in the field of industrial measurement and control instrumentation, and their SBG series of products showcases the company's commitment to quality and innovation. The SBG22445, SBG25872, SBG41705, and SBG25873 are distinct models within the SBG line, each engineered to address specific measurement challenges while delivering exceptional accuracy and reliability.The SBG22445 model is typically designed for high-performance temperature measurement, utilizing advanced thermocouple technology. It can operate over a broad temperature range, making it suitable for various industrial applications. With its digital display and user-friendly interface, this device allows for quick readings and easy calibration, ensuring that users can monitor temperature fluctuations in real-time.

Moving on to the SBG25872 model, this device specializes in humidity and temperature measurement. It integrates sophisticated sensors that combine precision with a rapid response time, ideal for environments where humidity and temperature conditions fluctuate frequently. The built-in data logging features allow for the collection of historical data, enabling users to analyze trends and ensure optimal conditions for processes sensitive to environmental changes.

The SBG41705 is tailored for pressure measurement, bringing advanced piezoresistive technology into play. This model is particularly useful in applications requiring accurate and continuous pressure monitoring. Equipped with a robust housing and protection from external elements, the SBG41705 excels in harsh industrial environments, providing reliable performance even under challenging conditions.

Lastly, the SBG25873 serves as a multifunctional device capable of measuring various parameters, including temperature, pressure, and humidity. This versatility makes it an invaluable asset in industrial settings where monitoring multiple variables is crucial for operational efficiency. Its user-friendly interface and extensive connectivity options enable seamless integration into existing systems, further enhancing its utility.

In summary, the Omega Engineering SBG series, represented by models like the SBG22445, SBG25872, SBG41705, and SBG25873, reflects the company's dedication to precision measurement. Their innovative use of advanced technologies and durable construction makes them indispensable tools in various industrial and research applications. Users can rely on these devices not only for accuracy and efficiency but also for ease of use, ensuring that they can focus on achieving their operational goals.