LV132

Electro-Optic Conductivity Sensor

Instruction Sheet M1800/1299

DESCRIPTION

The compact, LV132 Conductivity Sensor, with

SENSOR OPERATING PRINCIPLE

The sensor has the capability of discriminating between conductive and

WARNING

The nature of the sensor is that it is a

UNPACKING

Remove the Packing List and verify that you have received all equipment. If you have any questions about the shipment, please call the OMEGA Customer Service Department at

When you receive the shipment, inspect the container and equipment for any signs of damage. Note any evidence of rough handling in transit. Immediately report any damage to the shipping agent.

NOTE

The carrier will not honor any claims unless all shipping material is saved for their examination. After examining and removing contents, save packing material and carton in the event reshipment is necessary.

INSTALLATION - Running of Field Wire

A.The conductors of the intrinsically safe circuit should be sealed in a rigid metal conduit at the point where the wiring enters the hazardous area. The wiring and contacting device should be such that conductive dusts in the area will not close the circuit in place of the contacts.

B.Hazardous area field wiring will store energy due to distributed capacitance and inductance in proportion to its length. The maximum run of cable has been defined at 750 feet between barrier and sensor.

C.Shielded cable is not required, but if used in the application, the shield must be returned to ground. The shield must be con- nected to barrier earth ground.

D.Intrinsically safe wiring must be installed in accordance with Article 504 of the NEC,

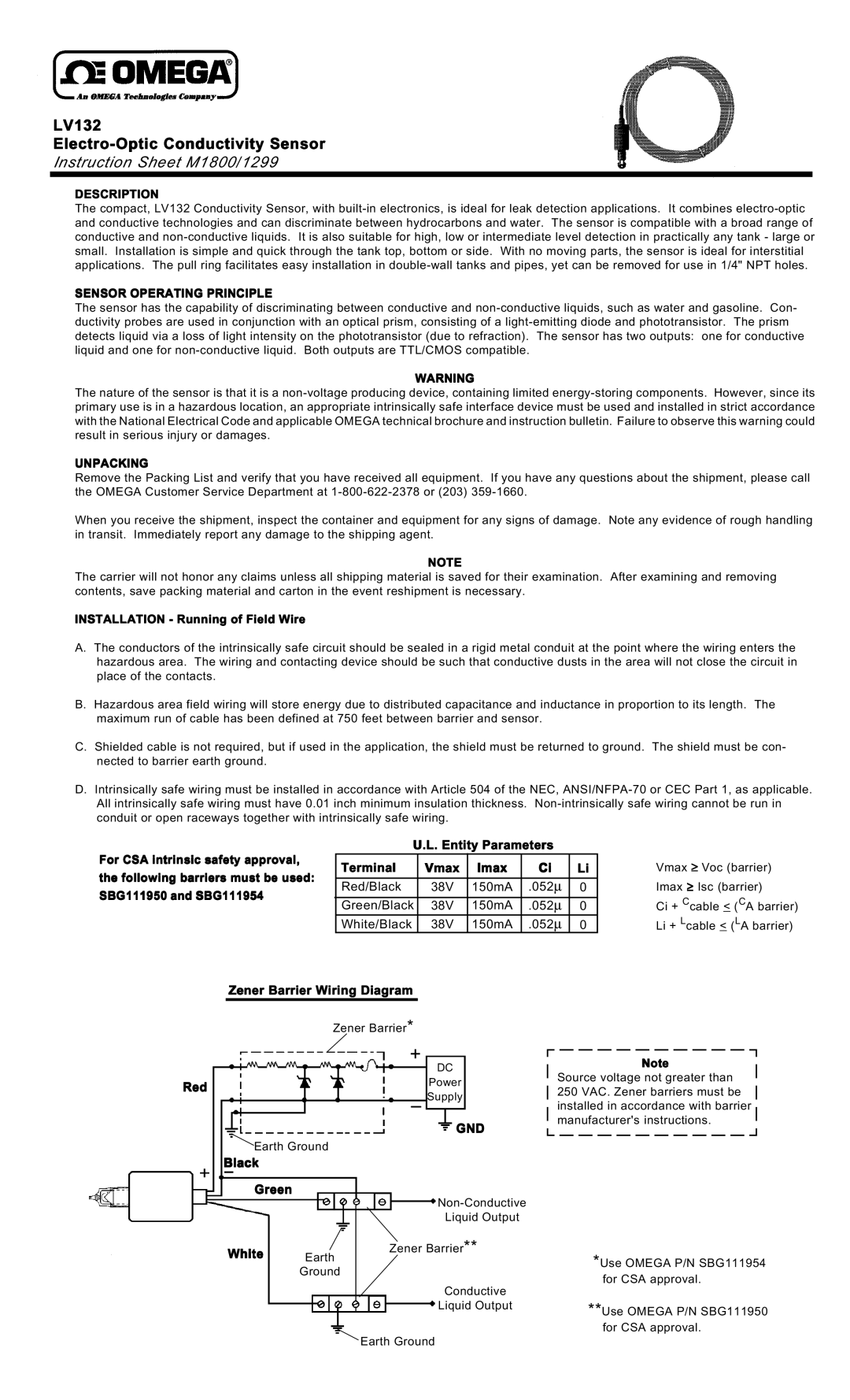

U.L. Entity Parameters

For CSA intrinsic safety approval, | Terminal | Vmax | Imax | Ci | Li | Vmax ≥ | Voc (barrier) | ||

the following barriers must be used: | |||||||||

Red/Black | 38V | 150mA | .052∝ | 0 | Imax ≥ | Isc (barrier) | |||

SBG111950 and SBG111954 |

| ||||||||

|

|

|

|

|

|

|

| ||

| Green/Black | 38V | 150mA | .052∝ | 0 | Ci + Ccable < (CA barrier) | |||

|

| ||||||||

|

| White/Black | 38V | 150mA | .052∝ | 0 | Li + Lcable < (LA barrier) | ||

Zener Barrier Wiring Diagram | ||

| Zener Barrier* | |

| + | |

| DC | |

Red | Power | |

_ Supply | ||

| ||

| GND | |

Earth Ground | ||

Black |

| |

Green | ||

| ||

| Liquid Output | |

White | Zener Barrier** | |

Earth | ||

Ground

Conductive

Liquid Output

Earth Ground

Note

Source voltage not greater than 250 VAC. Zener barriers must be installed in accordance with barrier manufacturer's instructions.

*Use OMEGA P/N SBG111954 for CSA approval.

**Use OMEGA P/N SBG111950 for CSA approval.