LVR300 Series Programming Positions & Operation

LVR300 Series Programming Positions & Operation

On

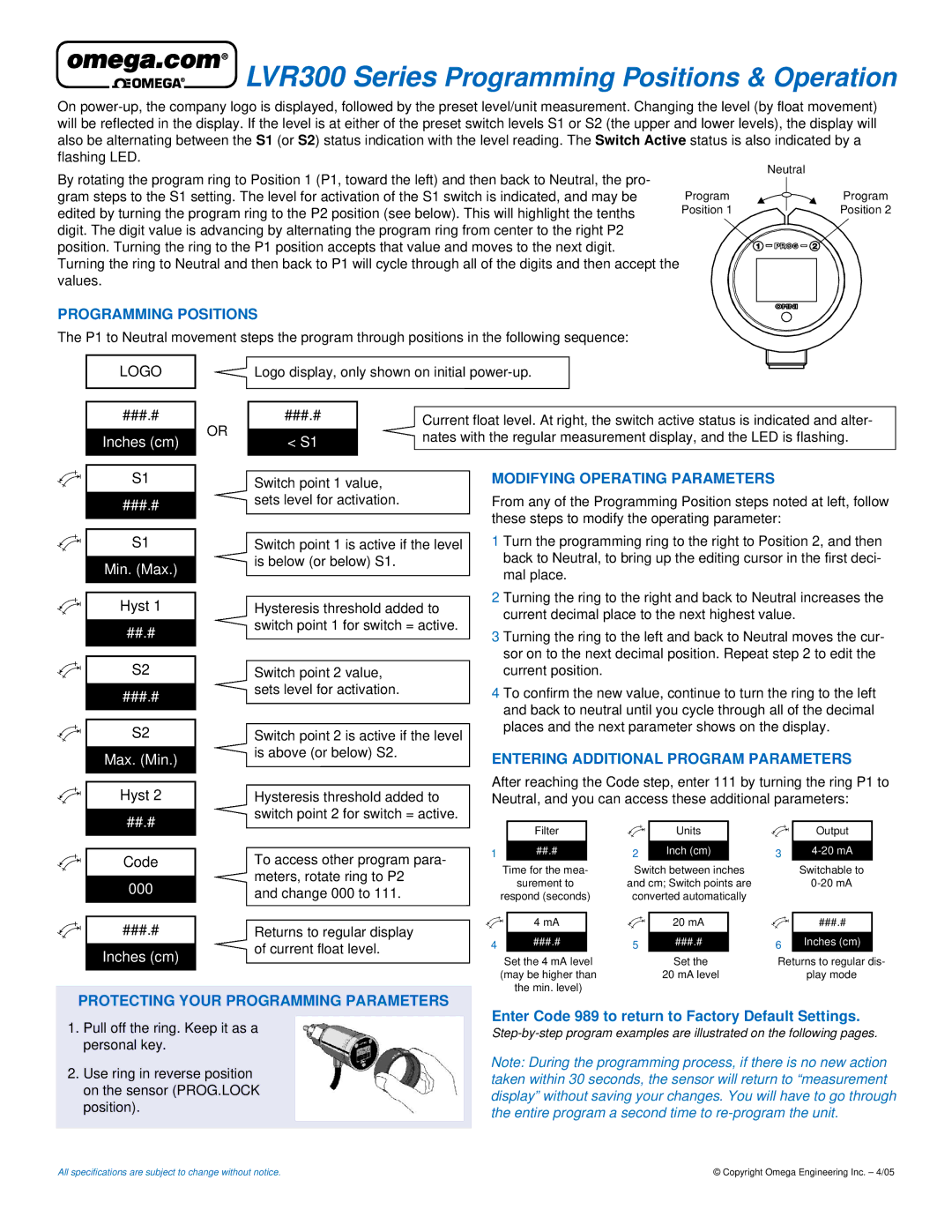

By rotating the program ring to Position 1 (P1, toward the left) and then back to Neutral, the pro- gram steps to the S1 setting. The level for activation of the S1 switch is indicated, and may be edited by turning the program ring to the P2 position (see below). This will highlight the tenths digit. The digit value is advancing by alternating the program ring from center to the right P2 position. Turning the ring to the P1 position accepts that value and moves to the next digit.

Turning the ring to Neutral and then back to P1 will cycle through all of the digits and then accept the values.

| Neutral |

Program | Program |

Position 1 | Position 2 |

1 | 2 |

PROGRAMMING POSITIONS

The P1 to Neutral movement steps the program through positions in the following sequence:

LOGO

Logo display, only shown on initial

###.#

Inches (cm)

S1

###.#

OR

###.#

< S1

Switch point 1 value, sets level for activation.

Current float level. At right, the switch active status is indicated and alter- nates with the regular measurement display, and the LED is flashing.

MODIFYING OPERATING PARAMETERS

From any of the Programming Position steps noted at left, follow these steps to modify the operating parameter:

S1

Min. (Max.)

Hyst 1

##.#

S2

###.#

S2

Max. (Min.)

Hyst 2

##.#

Code

000

###.#

Inches (cm)

Switch point 1 is active if the level is below (or below) S1.

Hysteresis threshold added to switch point 1 for switch = active.

Switch point 2 value, sets level for activation.

Switch point 2 is active if the level is above (or below) S2.

Hysteresis threshold added to switch point 2 for switch = active.

To access other program para- meters, rotate ring to P2

and change 000 to 111.

Returns to regular display of current float level.

1 Turn the programming ring to the right to Position 2, and then back to Neutral, to bring up the editing cursor in the first deci- mal place.

2 Turning the ring to the right and back to Neutral increases the current decimal place to the next highest value.

3 Turning the ring to the left and back to Neutral moves the cur- sor on to the next decimal position. Repeat step 2 to edit the current position.

4 To confirm the new value, continue to turn the ring to the left and back to neutral until you cycle through all of the decimal places and the next parameter shows on the display.

ENTERING ADDITIONAL PROGRAM PARAMETERS

After reaching the Code step, enter 111 by turning the ring P1 to Neutral, and you can access these additional parameters:

|

| Filter |

|

| Units |

|

| Output |

|

1 |

| ##.# |

| 2 | Inch (cm) |

| 3 |

|

|

| Time for the mea- | Switch between inches |

| Switchable to | |||||

|

| surement to | and cm; Switch points are |

| |||||

| respond (seconds) | converted automatically |

|

|

| ||||

|

|

|

|

|

|

|

| ||

|

| 4 mA |

|

| 20 mA |

|

| ###.# |

|

4 |

| ###.# |

| 5 | ###.# |

| 6 | Inches (cm) |

|

| Set the 4 mA level |

| Set the | Returns to regular dis- | |||||

| (may be higher than |

| 20 mA level |

| play mode | ||||

|

| the min. level) |

|

|

|

|

|

| |

PROTECTING YOUR PROGRAMMING PARAMETERS

1.Pull off the ring. Keep it as a personal key.

2.Use ring in reverse position on the sensor (PROG.LOCK position).

Enter Code 989 to return to Factory Default Settings.

Note: During the programming process, if there is no new action taken within 30 seconds, the sensor will return to “measurement display” without saving your changes. You will have to go through the entire program a second time to

All specifications are subject to change without notice. | © Copyright Omega Engineering Inc. – 4/05 |