20.0 specifications

Omnimount 20.0 is an innovative mounting solution that has garnered significant attention for its advanced features, cutting-edge technologies, and user-friendly characteristics. Designed to enhance the way users interact with their audiovisual equipment, Omnimount 20.0 aims to deliver unmatched flexibility and robust performance whether at home, in educational institutions, or within corporate environments.One of the standout features of Omnimount 20.0 is its versatile mounting options. The system supports a wide range of devices, from televisions to projectors, ensuring compatibility with various display sizes and weights. This adaptability makes it an ideal choice for any space, whether it’s a small living room or a large conference hall.

The technology behind Omnimount 20.0 is also noteworthy. The solution incorporates advanced tilt and swivel capabilities, allowing for optimal viewing angles without the hassle of manual adjustments. This feature is particularly beneficial in environments where multiple viewers are present, as it helps to minimize glare and enhance the overall viewing experience. Additionally, the quick-release mechanism simplifies installation and maintenance, giving users the convenience of easily accessing their devices for upgrades or repairs.

Durability and build quality are key characteristics of Omnimount 20.0. Constructed from high-grade materials, this mounting solution is engineered to withstand the test of time. It is designed to securely hold heavier devices, providing peace of mind to users concerned about stability and safety. The sleek, modern design seamlessly complements contemporary spaces, making it not just functional but also visually appealing.

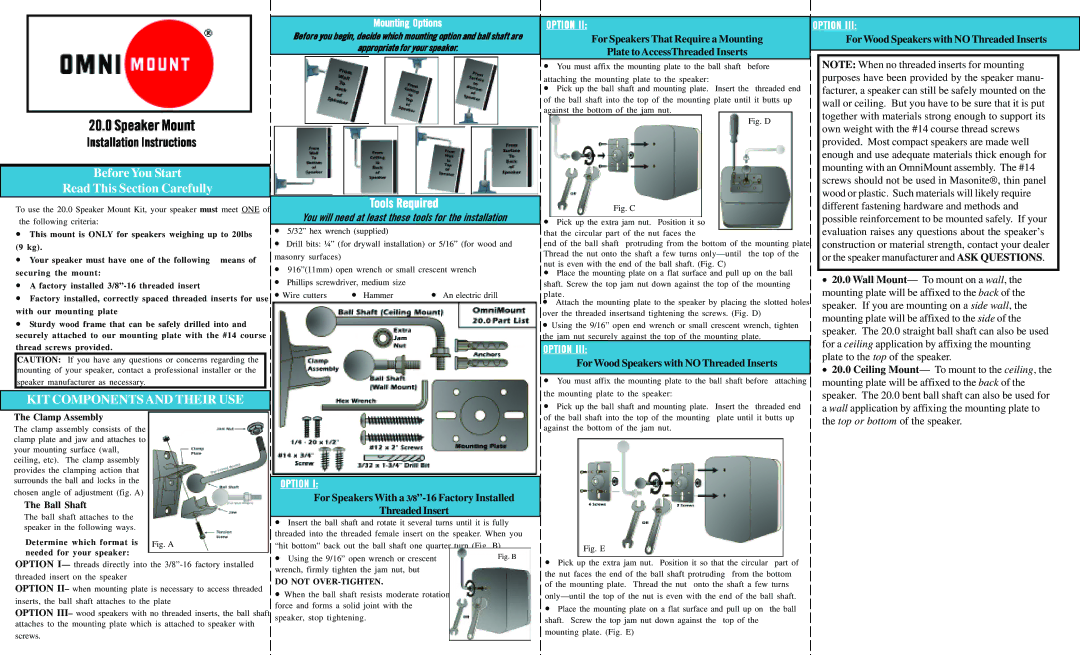

Another significant aspect of Omnimount 20.0 is its ease of installation. Accompanied by detailed instructions and all necessary hardware, the mounting solution can be set up quickly, even by those with limited technical skills. The intuitive mounting bracket system eliminates guesswork, ensuring that users can confidently install their equipment.

In conclusion, Omnimount 20.0 represents a remarkable advancement in the realm of mounting solutions. With its versatile compatibility, innovative technologies, robust design, and user-friendly characteristics, it stands as a top choice for anyone looking to enhance their audiovisual experience. Whether for personal or professional use, Omnimount 20.0 delivers on its promise of quality and convenience, making it a must-have product in today’s tech-savvy world.