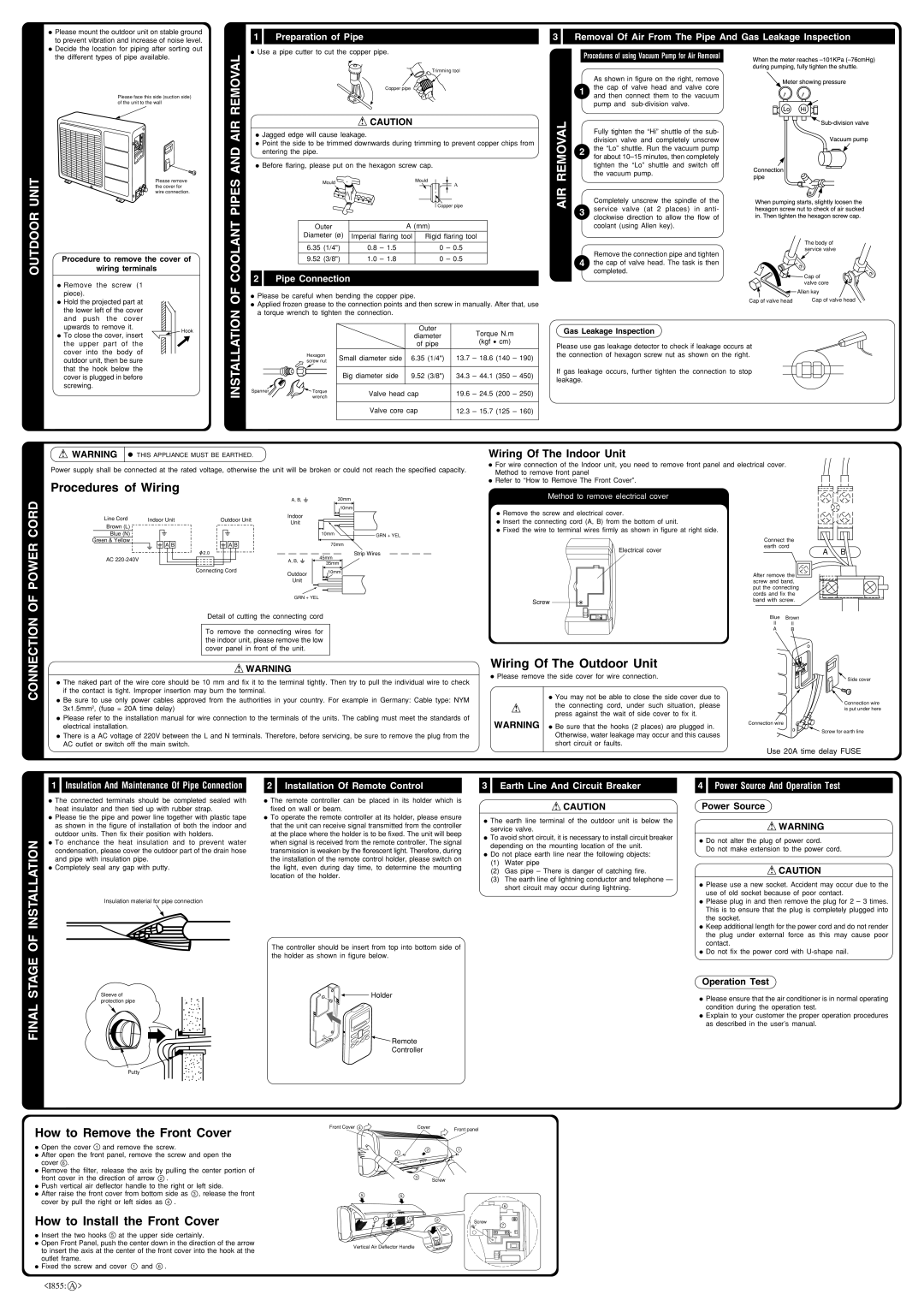

OUTDOOR UNIT

●Please mount the outdoor unit on stable ground to prevent vibration and increase of noise level.

●Decide the location for piping after sorting out the different types of pipe available.

Please face this side (suction side) of the unit to the wall

Please remove the cover for wire connection.

Procedure to remove the cover of

wiring terminals

● Remove the screw (1 piece).

● Hold the projected part at the lower left of the cover and push the cover upwards to remove it.

Hook

● To close the cover, insert the upper part of the cover into the body of outdoor unit, then be sure that the hook below the cover is plugged in before screwing.

INSTALLATION OF COOLANT PIPES AND AIR REMOVAL

1Preparation of Pipe

●Use a pipe cutter to cut the copper pipe.

Trimming tool

Copper pipe

!CAUTION

●Jagged edge will cause leakage.

●Point the side to be trimmed downwards during trimming to prevent copper chips from entering the pipe.

●Before flaring, please put on the hexagon screw cap.

| Mould | | | Mould | A |

| | | |

| | | | |

| | | | Copper pipe |

Outer | | A (mm) | |

Diameter (ø) | Imperial flaring tool | Rigid flaring tool |

6.35 | (1/4") | 0.8 | – 1.5 | 0 | – 0.5 |

9.52 | (3/8") | 1.0 | – 1.8 | 0 | – 0.5 |

2Pipe Connection

●Please be careful when bending the copper pipe.

●Applied frozen grease to the connection points and then screw in manually. After that, use a torque wrench to tighten the connection.

| | | Outer | | Torque N.m |

| | | diameter | |

| | | | (kgf ● cm) | |

| | | of pipe | | |

| | | | | | |

| Hexagon | Small diameter side | 6.35 (1/4") | 13.7 | – 18.6 | (140 | – 190) |

| screw nut |

| | | | | | |

| | Big diameter side | 9.52 (3/8") | 34.3 | – 44.1 | (350 | – 450) |

Spanner | Torque | Valve head cap | 19.6 | – 24.5 | (200 | – 250) |

| wrench |

| | | | | | |

| | Valve core cap | 12.3 | – 15.7 | (125 | – 160) |

3 Removal Of Air From The Pipe And Gas Leakage Inspection

Procedures of using Vacuum Pump for Air Removal

As shown in figure on the right, remove the cap of valve head and valve core

1and then connect them to the vacuum

pump and sub-division valve.

REMOVAL | | Fully tighten the “Hi” shuttle of the sub- |

| |

| | division valve and completely unscrew |

| 2 | the “Lo” shuttle. Run the vacuum pump |

| for about 10–15 minutes, then completely |

| |

| | tighten the “Lo” shuttle and switch off |

| | the vacuum pump. |

AIR | | Completely unscrew the spindle of the |

| |

3 service valve (at 2 places) in anti- clockwise direction to allow the flow of coolant (using Allen key).

The body of service valve

Remove the connection pipe and tighten

4the cap of valve head. The task is then completed.

Cap of valve core

Cap of valve core

Allen key

Allen key

Cap of valve head | Cap of valve head |

Gas Leakage Inspection

Please use gas leakage detector to check if leakage occurs at the connection of hexagon screw nut as shown on the right.

If gas leakage occurs, further tighten the connection to stop leakage.

CORD

!WARNING ● THIS APPLIANCE MUST BE EARTHED.

Power supply shall be connected at the rated voltage, otherwise the unit will be broken or could not reach the specified capacity.

Procedures of Wiring

| | | | | | | | | | | | | A, B, | | | | 30mm |

| | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | |

Line Cord | Indoor Unit | Outdoor Unit | Indoor | | | 10mm | |

| | | | |

| | | | |

Unit | | | | | | |

Brown (L) | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | |

Blue (N) | | | | | | | | | | | | | | | | | 10mm | | | | GRN + YEL |

Wiring Of The Indoor Unit

●For wire connection of the Indoor unit, you need to remove front panel and electrical cover. Method to remove front panel

●Refer to “How to Remove The Front Cover”.

Method to remove electrical cover

●Remove the screw and electrical cover.

●Insert the connecting cord (A, B) from the bottom of unit.

●Fixed the wire to terminal wires firmly as shown in figure at right side.

CONNECTION OF POWER

Green & Yellow | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | A | B | | | | | A | B | | | | | | | | | | | | | | | 70mm |

| | | | | | | | | | 2.0 | | | | | | | | | | | | | | | | | | | | | | | | Strip Wires |

| AC 220-240V | | | | | | | | | | | | | A, B, | | | | | | | | | 45mm | |

| | | | | | | | | | | | | | | | | | | | | | 35mm |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | Connecting Cord | Outdoor | | | | | | | | 10mm |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | Unit | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | |

GRN + YEL

Detail of cutting the connecting cord

To remove the connecting wires for the indoor unit, please remove the low cover panel in front of the unit.

!WARNING

●The naked part of the wire core should be 10 mm and fix it to the terminal tightly. Then try to pull the individual wire to check if the contact is tight. Improper insertion may burn the terminal.

●Be sure to use only power cables approved from the authorities in your country. For example in Germany: Cable type: NYM 3x1.5mm2, (fuse = 20A time delay)

●Please refer to the installation manual for wire connection to the terminals of the units. The cabling must meet the standards of electrical installation.

●There is a AC voltage of 220V between the L and N terminals. Therefore, before servicing, be sure to remove the plug from the AC outlet or switch off the main switch.

Electrical cover

Screw

AUTO

RESTART

SWITCH

Wiring Of The Outdoor Unit

●Please remove the side cover for wire connection.

●You may not be able to close the side cover due to

!the connecting cord, under such situation, please press against the wait of side cover to fix it.

WARNING ● Be sure that the hooks (2 places) are plugged in. Otherwise, water leakage may occur and this causes short circuit or faults.

Connect the earth cord

A B

After remove the screw and band, put the connecting cords and fix the band with screw.

Blue Brown

llII

A B

Side cover

Connection wire is put under here

Connection wire

Screw for earth line

Use 20A time delay FUSE

FINAL STAGE OF INSTALLATION

1Insulation And Maintenance Of Pipe Connection

●The connected terminals should be completed sealed with heat insulator and then tied up with rubber strap.

●Please tie the pipe and power line together with plastic tape as shown in the figure of installation of both the indoor and outdoor units. Then fix their position with holders.

●To enchance the heat insulation and to prevent water condensation, please cover the outdoor part of the drain hose and pipe with insulation pipe.

●Completely seal any gap with putty.

Insulation material for pipe connection

Sleeve of protection pipe

Putty

2Installation Of Remote Control

●The remote controller can be placed in its holder which is fixed on wall or beam.

●To operate the remote controller at its holder, please ensure that the unit can receive signal transmitted from the controller at the place where the holder is to be fixed. The unit will beep when signal is received from the remote controller. The signal transmission is weaken by the florescent light. Therefore, during the installation of the remote control holder, please switch on the light, even during day time, to determine the mounting location of the holder.

The controller should be insert from top into bottom side of the holder as shown in figure below.

Holder

Holder

Remote

Remote

Controller

3Earth Line And Circuit Breaker

!CAUTION

●The earth line terminal of the outdoor unit is below the service valve.

●To avoid short circuit, it is necessary to install circuit breaker depending on the mounting location of the unit.

●Do not place earth line near the following objects:

(1)Water pipe

(2)Gas pipe – There is danger of catching fire.

(3)The earth line of lightning conductor and telephone — short circuit may occur during lightning.

4Power Source And Operation Test

Power Source

!WARNING

●Do not alter the plug of power cord.

Do not make extension to the power cord.

!CAUTION

●Please use a new socket. Accident may occur due to the use of old socket because of poor contact.

●Please plug in and then remove the plug for 2 – 3 times. This is to ensure that the plug is completely plugged into the socket.

●Keep additional length for the power cord and do not render the plug under external force as this may cause poor contact.

●Do not fix the power cord with U-shape nail.

Operation Test

●Please ensure that the air conditioner is in normal operating condition during the operation test.

●Explain to your customer the proper operation procedures as described in the user’s manual.

How to Install the Front Cover

●Insert the two hooks 5 at the upper side certainly.

●Open Front Panel, push the center down in the direction of the arrow to insert the axis at the center of the front cover into the hook at the outlet frame.

●Fixed the screw and cover 1 and 6 .

7

Vertical Air Deflector Handle