hole, and the large hole lines up with the central hole in the baseplate. Thread an encoder board mounting screw into the predrilled starter hole with a Phillips screwdriver and tighten until just tight.

6.Place one fender washer (H) onto the azimuth axis screw

(I).Then push the screw up through the hole in the ground baseplate (A).Then slide the encoder disk (J), flat side down, onto the azimuth axis screw.

7.Place the brass bushing (F) onto the azimuth axis screw

(I)so that the wide end of the bushing is closest to the encoder disk (J). Seat the bushing onto the encoder disk so that the registration feature on the bushing goes into the hole in the encoder disk. You may need to move the encoder disk around on the azimuth axis screw a bit in order for the bushing to seat properly.

8.Carefully position the top baseplate (D) over the ground baseplate (A) and lower it so the brass bushing (F) goes into in the center hole of the top baseplate. Place the remaining fender washer (K) onto the shaft of the azimuth axis screw, then thread the hex lock nut (L) onto the end of the azimuth axis screw and tighten it finger tight, for now.

9.To tighten the azimuth axis screw (I) and hex lock nut (L), tilt the assembled Dobsonian base at a slight angle to lift the ground baseplate off the ground. Now, with one wrench (or pliers) hold the head of the azimuth axis screw still while turning the hex lock nut with the other wrench. Figure 4 shows this being done. Tighten the hex lock nut

a.

b.

Figure 4. To connect the baseplates, tilt them only slightly, as shown. Do not place them on their side. (a) Use one wrench to hold the hex nut steady (b) while turning the other end of the azimuth axis screw.

Correct Tension pads

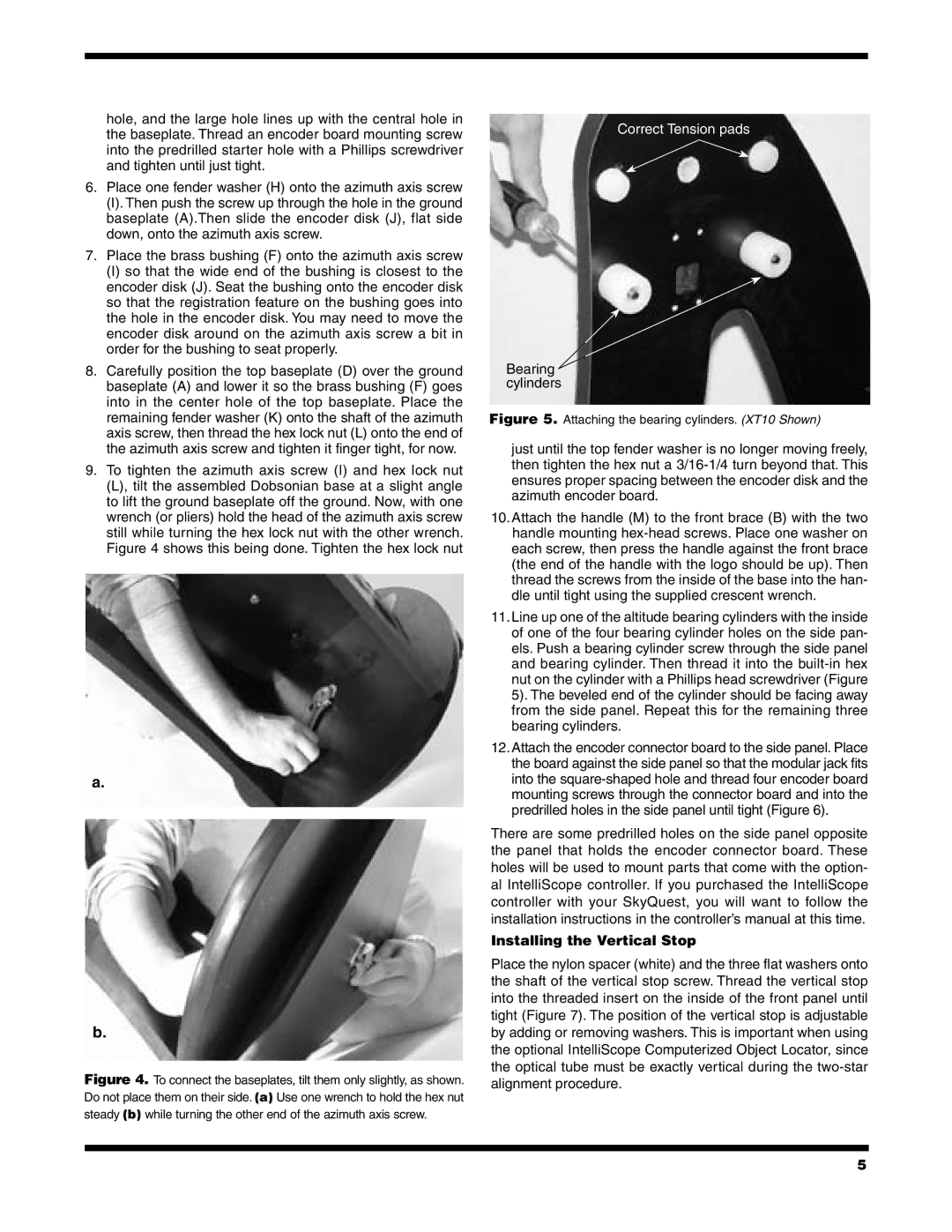

Bearing ![]() cylinders

cylinders

Figure 5. Attaching the bearing cylinders. (XT10 Shown)

just until the top fender washer is no longer moving freely, then tighten the hex nut a

10.Attach the handle (M) to the front brace (B) with the two handle mounting

11.Line up one of the altitude bearing cylinders with the inside of one of the four bearing cylinder holes on the side pan- els. Push a bearing cylinder screw through the side panel and bearing cylinder. Then thread it into the

12.Attach the encoder connector board to the side panel. Place the board against the side panel so that the modular jack fits into the

There are some predrilled holes on the side panel opposite the panel that holds the encoder connector board. These holes will be used to mount parts that come with the option- al IntelliScope controller. If you purchased the IntelliScope controller with your SkyQuest, you will want to follow the installation instructions in the controller’s manual at this time.

Installing the Vertical Stop

Place the nylon spacer (white) and the three flat washers onto the shaft of the vertical stop screw. Thread the vertical stop into the threaded insert on the inside of the front panel until tight (Figure 7). The position of the vertical stop is adjustable by adding or removing washers. This is important when using the optional IntelliScope Computerized Object Locator, since the optical tube must be exactly vertical during the

5