EJ (AEJ)

NOTES

1.To ensure proper operation, the voltage applied to the coil should be the rated operating voltage of the coil. Also, be aware that the

2.Heat, smoke, and even a fire may occur if the relay is used in conditions outside of the allowable ranges for the coil ratings, contact ratings, operating cycle lifetime, and other specifications. Therefore, do not use the relay if these ratings are exceeded.

3.If the relay has been dropped, the appearance and characteristics should always be checked before use.

4.This relay is for DC loads. Do not use it for AC load switching.

5.Make sure that the relay is wired

correctly. Incorrect wiring may cause unexpected events or the generation of heat or flames.

6.We recommend you use a surge absorbing element with a clamp voltage of 1.5 to 2.0 times the rated operating voltage for the relay coil drive circuit as a means for relay coil surge absorption. Please avoid the use of diodes, capacitors and resistors because they lead to degradation in

7.Avoid mounting the relay in strong magnetic fields (near a transformer or magnet) or close to an object that radiates heat.

8.Electrical life

This relay is a

In the event that the relay loses

9.If the power is turned off and then immediately on after applying the rated voltage (current) continuously to the relay’s coil and contact, the resistance of the coil will increase due to a rise in the coil temperature. This causes the

10.If you are using an inductive load (L load) such that L/R > 1 ms, add surge protection in parallel with the inductive load. If this is not done, the electrical life will decrease and

11.Be careful that foreign matter and oils and fats kind doesn’t stick to the main terminal part because it is likely to cause a terminal part to give off unusual heat.

12.Avoid excessive load applied to the terminal in case of installing such as a bus bar etc., because it might give bad influence to the opening and closing performance.

Tighten each of the screws within the rated ranges given below.

Main terminal (M6 screw): 6.0N·m to 8.0N·m

Main unit mounting (M5 screw): 2.5N·m to 3.6N·m

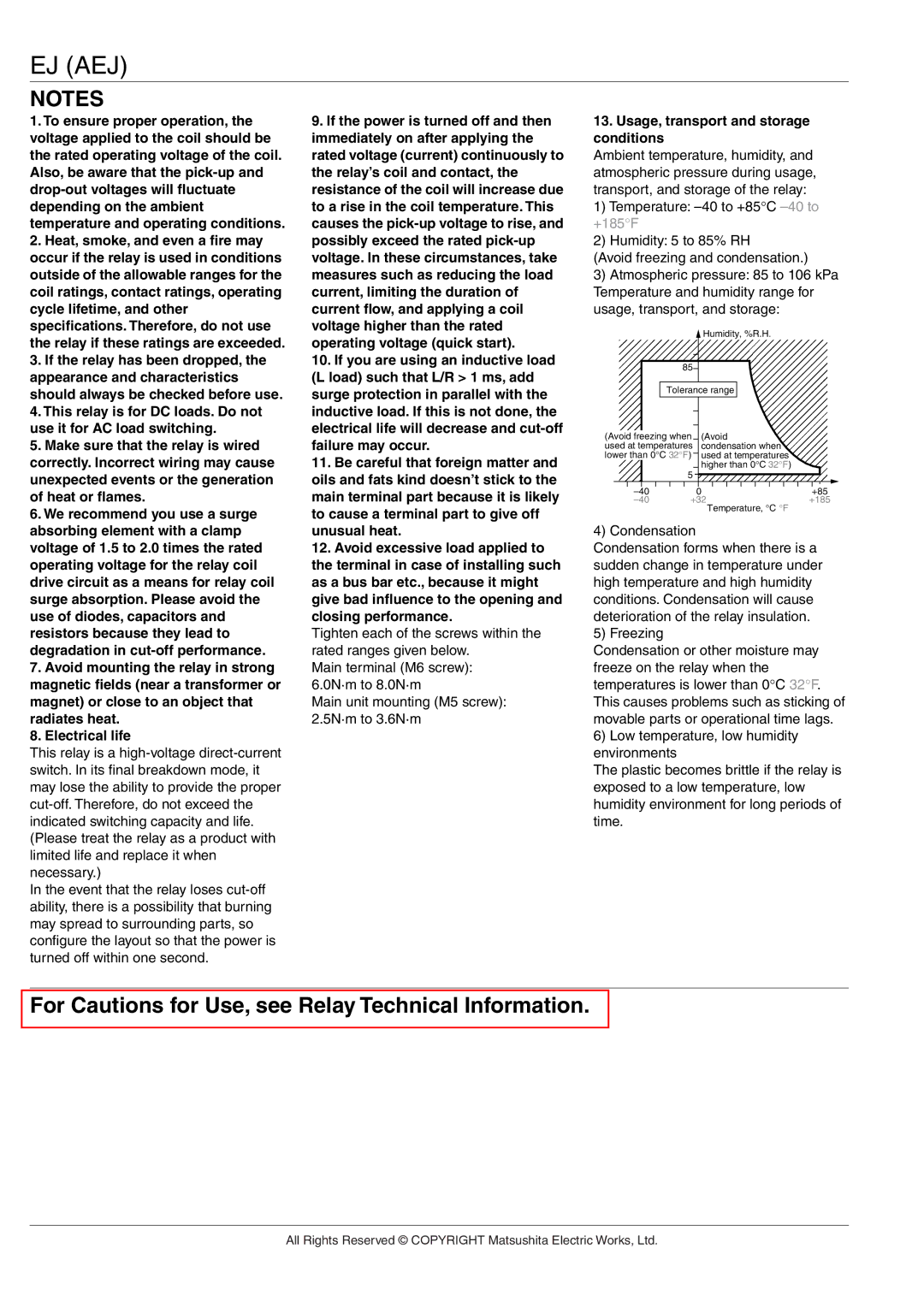

13.Usage, transport and storage conditions

Ambient temperature, humidity, and atmospheric pressure during usage,

transport, and storage of the relay:

1) Temperature:

+185°F

2) Humidity: 5 to 85% RH

(Avoid freezing and condensation.)

3) Atmospheric pressure: 85 to 106 kPa Temperature and humidity range for usage, transport, and storage:

|

|

|

|

|

| 85 |

| Humidity, %R.H. |

|

|

|

|

|

|

| |||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||

|

|

|

|

|

|

|

| Tolerance range |

|

|

|

|

|

|

|

| ||||||||||||||||

(Avoid freezing when |

| (Avoid |

|

|

|

|

|

|

| |||||||||||||||||||||||

|

|

|

|

|

|

|

| |||||||||||||||||||||||||

|

|

|

|

|

|

|

| |||||||||||||||||||||||||

used at temperatures |

| condensation when | ||||||||||||||||||||||||||||||

lower than 0°C 32°F) |

| used at temperatures | ||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||

|

|

|

|

|

| 5 |

| higher than 0°C 32°F) | ||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

| 0 |

|

|

|

|

|

|

|

|

|

|

| +85 | ||||||||||

|

|

| +32 |

|

|

|

|

|

|

|

|

|

|

| +185 | |||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| Temperature, °C | °F | |||||||||||||||||

4) Condensation

Condensation forms when there is a sudden change in temperature under high temperature and high humidity conditions. Condensation will cause deterioration of the relay insulation.

5) Freezing

Condensation or other moisture may freeze on the relay when the temperatures is lower than 0°C 32°F. This causes problems such as sticking of movable parts or operational time lags.

6)Low temperature, low humidity environments

The plastic becomes brittle if the relay is exposed to a low temperature, low humidity environment for long periods of time.

For Cautions for Use, see Relay Technical Information.

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.