. ASSEMBLY

. ASSEMBLY

![]() WARNING:

WARNING:

To reduce the risk of injury, always remove battery pack before chang- ing the blade.

Selecting a blade

The blade clamp sleeve can be used with all 1/2" shank universal reciprocat- ing saw blade. When selecting a blade, choose the right type and length.

Choose a length long enough to extend beyond the shoe and your work throughout the stroke. Do not use blades less than

Installing or removing the saw blade

![]() CAUTION:

CAUTION:

Always clean out all chips or foreign material adhering to the blade, blade clamp and/or slider before use. Failure to do so may cause insuf- ficient tightening of the blade, result- ing in a serious injury.

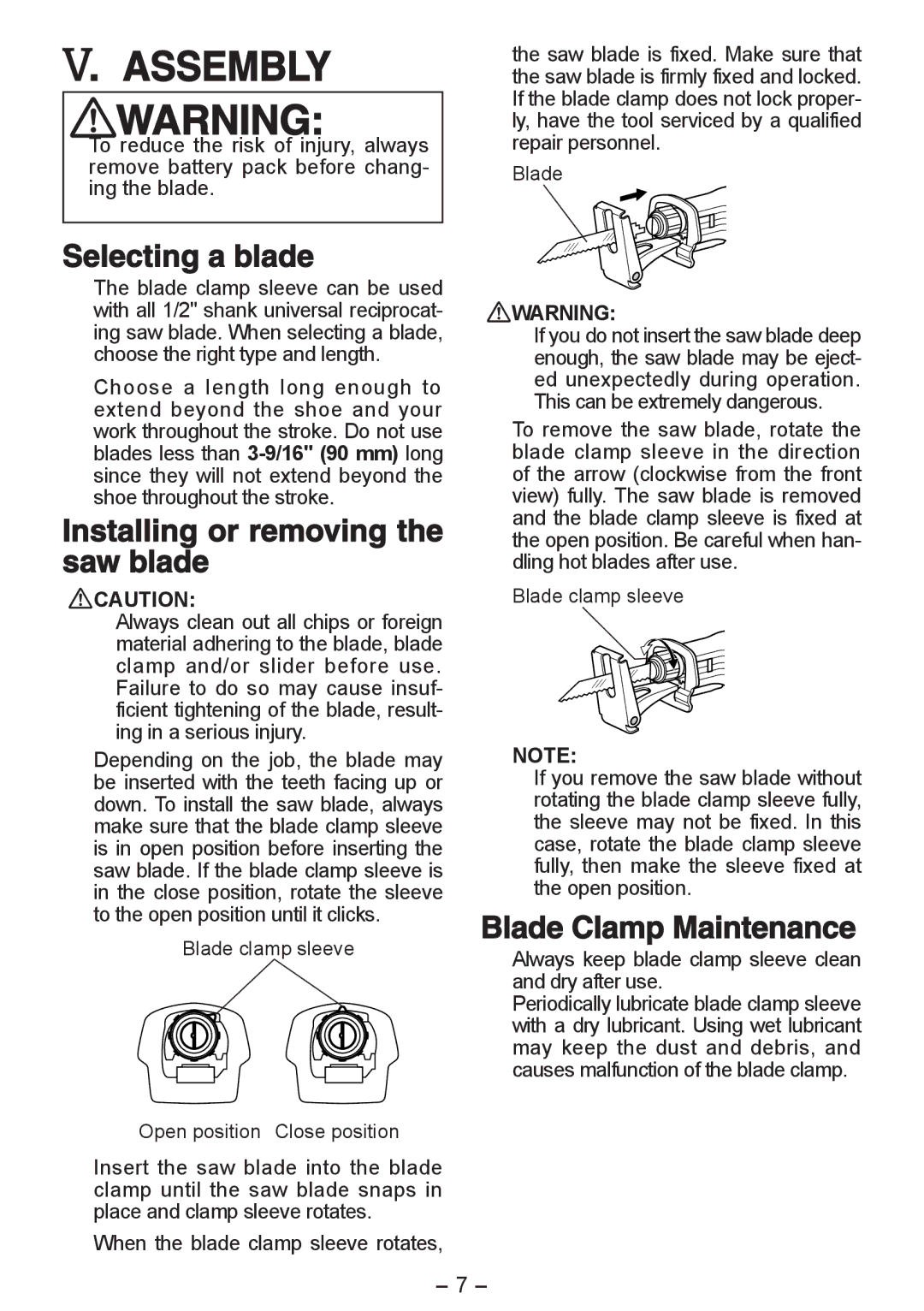

Depending on the job, the blade may be inserted with the teeth facing up or down. To install the saw blade, always make sure that the blade clamp sleeve is in open position before inserting the saw blade. If the blade clamp sleeve is in the close position, rotate the sleeve to the open position until it clicks.

Blade clamp sleeve

Open position Close position

Insert the saw blade into the blade clamp until the saw blade snaps in place and clamp sleeve rotates.

When the blade clamp sleeve rotates,

the saw blade is fixed. Make sure that the saw blade is firmly fixed and locked. If the blade clamp does not lock proper- ly, have the tool serviced by a qualified repair personnel.

Blade

![]() WARNING:

WARNING:

If you do not insert the saw blade deep enough, the saw blade may be eject- ed unexpectedly during operation. This can be extremely dangerous.

To remove the saw blade, rotate the blade clamp sleeve in the direction of the arrow (clockwise from the front view) fully. The saw blade is removed and the blade clamp sleeve is fixed at the open position. Be careful when han- dling hot blades after use.

Blade clamp sleeve

NOTE:

If you remove the saw blade without rotating the blade clamp sleeve fully, the sleeve may not be fixed. In this case, rotate the blade clamp sleeve fully, then make the sleeve fixed at the open position.

Blade Clamp Maintenance

Always keep blade clamp sleeve clean and dry after use.

Periodically lubricate blade clamp sleeve with a dry lubricant. Using wet lubricant may keep the dust and debris, and causes malfunction of the blade clamp.

- 7 -