PRECAUTIONS

!2

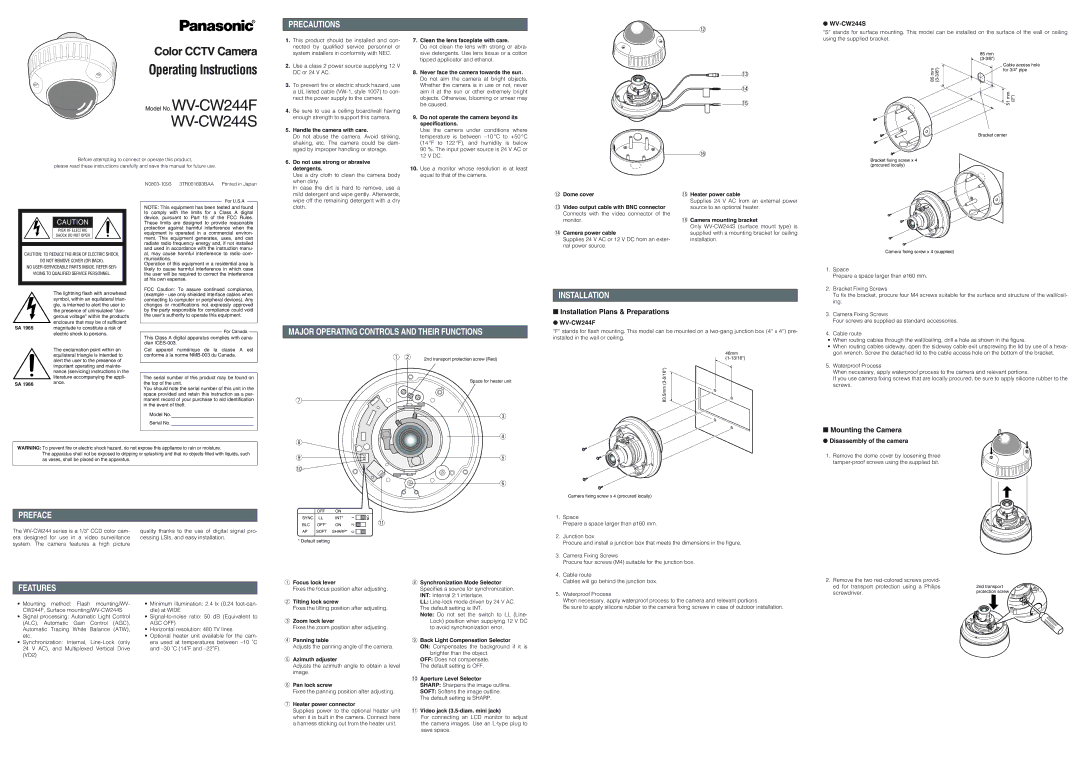

●WV-CW244S

“S” stands for surface mounting. This model can be installed on the surface of the wall or ceiling

Color CCTV Camera

Operating Instructions

Model

WV-CW244S

Before attempting to connect or operate this product,

please read these instructions carefully and save this manual for future use.

1. | This product should be installed and con- |

| nected by qualified service personnel or |

| system installers in conformity with NEC. |

2. | Use a class 2 power source supplying 12 V |

| DC or 24 V AC. |

3. | To prevent fire or electric shock hazard, use |

| a UL listed cable |

| nect the power supply to the camera. |

4. | Be sure to use a ceiling board/wall having |

| enough strength to support this camera. |

5. | Handle the camera with care. |

| Do not abuse the camera. Avoid striking, |

| shaking, etc. The camera could be dam- |

| aged by improper handling or storage. |

6. | Do not use strong or abrasive |

| detergents. |

| Use a dry cloth to clean the camera body |

| when dirty. |

7.Clean the lens faceplate with care.

Do not clean the lens with strong or abra- sive detergents. Use lens tissue or a cotton tipped applicator and ethanol.

8.Never face the camera towards the sun. Do not aim the camera at bright objects. Whether the camera is in use or not, never aim it at the sun or other extremely bright objects. Otherwise, blooming or smear may be caused.

9.Do not operate the camera beyond its

specifications.

Use the camera under conditions where temperature is between

10.Use a monitor whose resolution is at least equal to that of the camera.

!3

!4

!5

!6

using the supplied bracket.

85 mm

mm85 | Cable access hole | |

for 3/4" pipe | ||

| ||

| 51 mm (2") |

Bracket center

Bracket fixing screw x 4 (procured locally)

CAUTION

RISK OF ELECTRIC

SHOCK DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK).

NO

VICING TO QUALIFIED SERVICE PERSONNEL.

The lightning flash with arrowhead symbol, within an equilateral trian- gle, is interned to alert the user to the presence of uninsulated "dan- gerous voltage" within the product's enclosure that may be of sufficient

SA 1965 magnitude to constitute a risk of electric shock to persons.

| The exclamation point within an |

| equilateral triangle is intended to |

| alert the user to the presence of |

| important operating and mainte- |

| nance (servicing) instructions in the |

| literature accompanying the appli- |

SA 1966 | ance. |

|

For U.S.A

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environ- ment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manu- al, may cause harmful interference to radio com- munications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

FCC Caution: To assure continued compliance, (example - use only shielded interface cables when connecting to computer or peripheral devices). Any changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate this equipment.

For Canada

This Class A digital apparatus complies with cana- dian

Cet appareil numérique de la classe A est conforme à la norme

The serial number of this product may be found on the top of the unit.

You should note the serial number of this unit in the space provided and retain this instruction as a per- manent record of your purchase to aid identification in the event of theft.

Model No.

Serial No.

In case the dirt is hard to remove, use a |

mild detergent and wipe gently. Afterwards, |

wipe off the remaining detergent with a dry |

cloth. |

MAJOR OPERATING CONTROLS AND THEIR FUNCTIONS

q w | 2nd transport protection screw (Red) |

| |

| Space for heater unit |

u |

|

| e |

i | r |

|

!2Dome cover | !5Heater power cable |

| Supplies 24 V AC from an external power |

!3Video output cable with BNC connector | source to an optional heater. |

Connects with the video connector of the |

|

monitor. | !6Camera mounting bracket |

| Only |

!4Camera power cable | supplied with a mounting bracket for ceiling |

Supplies 24 V AC or 12 V DC from an exter- | installation. |

nal power source. |

|

INSTALLATION

■Installation Plans & Preparations

●WV-CW244F

“F” stands for flash mounting. This model can be mounted on a

46mm

83.5mm

Camera fixing screw x 4 (supplied)

1.Space

Prepare a space larger than ø160 mm.

2.Bracket Fixing Screws

To fix the bracket, procure four M4 screws suitable for the surface and structure of the wall/ceil- ing.

3.Camera Fixing Screws

Four screws are supplied as standard accessories.

4.Cable route

•When routing cables through the wall/ceiling, drill a hole as shown in the figure.

•When routing cables sideway, open the sideway cable exit unscrewing the lid by use of a hexa- gon wrench. Screw the detached lid to the cable access hole on the bottom of the bracket.

5.Waterproof Process

When necessary, apply waterproof process to the camera and relevant portions.

If you use camera fixing screws that are locally procured, be sure to apply silicone rubber to the screws.

■ Mounting the Camera

● Disassembly of the camera

WARNING: To prevent fire or electric shock hazard, do not expose this appliance to rain or moisture.

The apparatus shall not be exposed to dripping or splashing and that no objects filled with liquids, such as vases, shall be placed on the apparatus.

PREFACE

The | quality thanks to the use of digital signal pro- |

era designed for use in a video surveillance | cessing LSIs, and easy installation. |

system. The camera features a high picture |

|

o |

|

|

|

| t | |

!0 |

|

|

|

|

| |

|

|

|

|

| y | |

| OFF | ON |

|

|

| |

SYNC | LL | INT* | 1 2 | ON | !1 | |

BLC | OFF* | ON | ||||

|

|

| ||||

AP | SOFT | SHARP* | 3 |

|

|

* Default setting

Camera fixing screw x 4 (procured locally)

1. | Space |

| Prepare a space larger than ø160 mm. |

2. | Junction box |

| Procure and install a junction box that meets the dimensions in the figure. |

3. | Camera Fixing Screws |

| Procure four screws (M4) suitable for the junction box. |

4. | Cable route |

1. Remove the dome cover by loosening three

FEATURES

• Mounting method: Flash mounting/WV- | • Minimum illumination: 2.4 lx (0.24 |

CW244F, Surface | dle) at WIDE |

• Signal processing: Automatic Light Control | • |

(ALC), Automatic Gain Control (AGC), | AGC OFF) |

Automatic Tracing White Balance (ATW), | • Horizontal resolution: 480 TV lines |

etc. | • Optional heater unit available for the cam- |

• Synchronization: Internal, | era used at temperatures between |

24 V AC), and Multiplexed Vertical Drive | and |

(VD2) |

|

qFocus lock lever

Fixes the focus position after adjusting.

wTilting lock screw

Fixes the tilting position after adjusting.

eZoom lock lever

Fixes the zoom position after adjusting.

rPanning table

Adjusts the panning angle of the camera.

tAzimuth adjuster

Adjusts the azimuth angle to obtain a level image.

yPan lock screw

Fixes the panning position after adjusting.

uHeater power connector

Supplies power to the optional heater unit when it is built in the camera. Connect here a harness sticking out from the heater unit.

iSynchronization Mode Selector Specifies a source for synchronization. INT: Internal 2:1 interlace.

LL:

Note: Do not set the switch to LL (Line- Lock) position when supplying 12 V DC to avoid synchronization error.

oBack Light Compensation Selector

ON: Compensates the background if it is brighter than the object.

OFF: Does not compensate. The default setting is OFF.

!0Aperture Level Selector SHARP: Sharpens the image outline. SOFT: Softens the image outline. The default setting is SHARP.

!1Video jack

For connecting an LCD monitor to adjust the camera images. Use an

Cables will go behind the junction box. |

5. Waterproof Process |

When necessary, apply waterproof process to the camera and relevant portions. |

Be sure to apply silicone rubber to the camera fixing screws in case of outdoor installation. |

2. Remove the two |

|

ed for transport protection using a Philips | 2nd transport |

screwdriver. | protection screw |