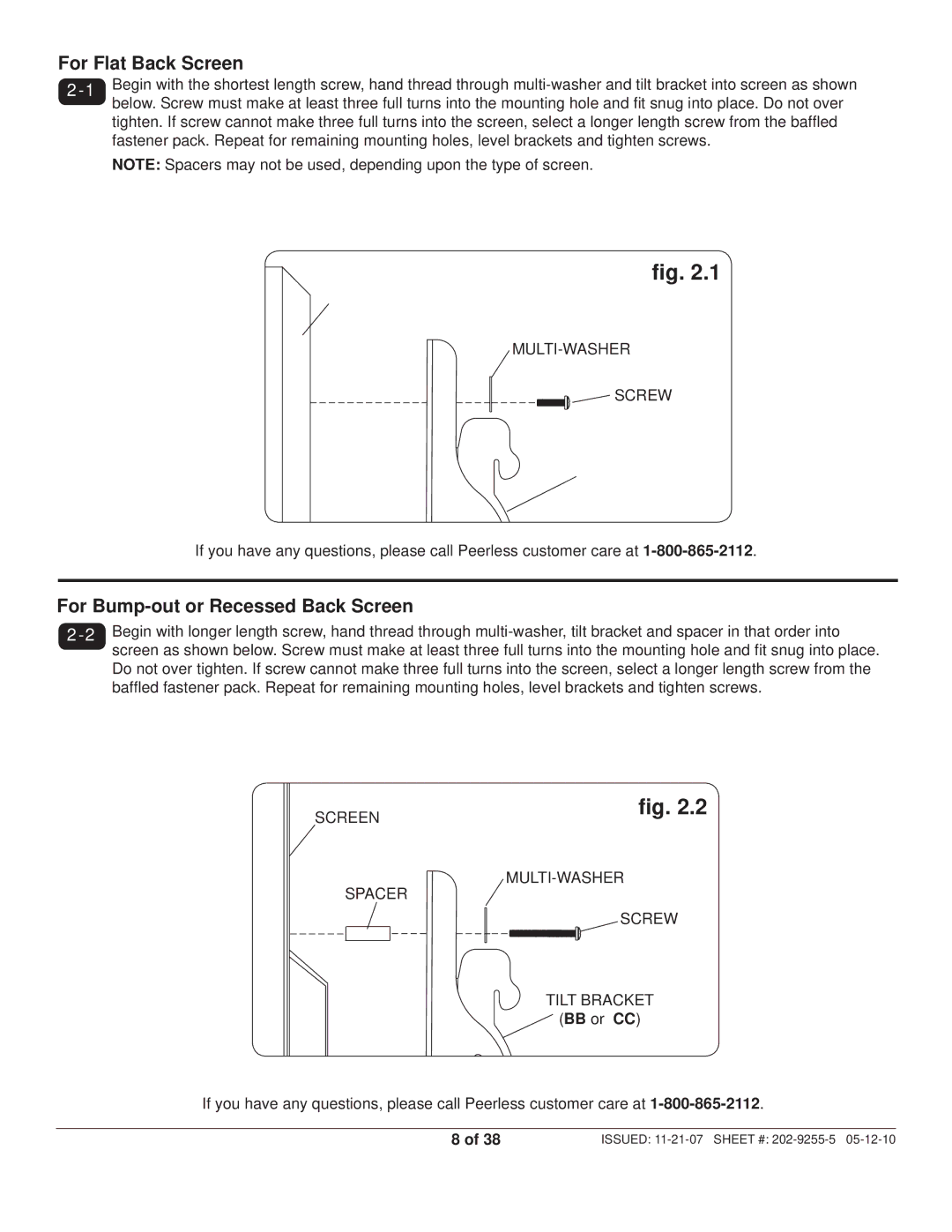

For Flat Back Screen

Begin with the shortest length screw, hand thread through | |

| below. Screw must make at least three full turns into the mounting hole and fit snug into place. Do not over |

tighten. If screw cannot make three full turns into the screen, select a longer length screw from the baffled fastener pack. Repeat for remaining mounting holes, level brackets and tighten screws.

NOTE: Spacers may not be used, depending upon the type of screen.

fig. 2.1

SCREEN

![]()

![]() SCREW

SCREW

TILT BRACKET

![]()

![]() (BB or CC)

(BB or CC)

If you have any questions, please call Peerless customer care at

For Bump-out or Recessed Back Screen

SCREEN

SPACER

fig. 2.2

MULTI-WASHER

SCREW

TILT BRACKET

![]() (BB or CC)

(BB or CC)

If you have any questions, please call Peerless customer care at

8 of 38 | ISSUED: |