MegaTherm Commercial Pool Heating Boiler | Page 9 |

|

|

|

|

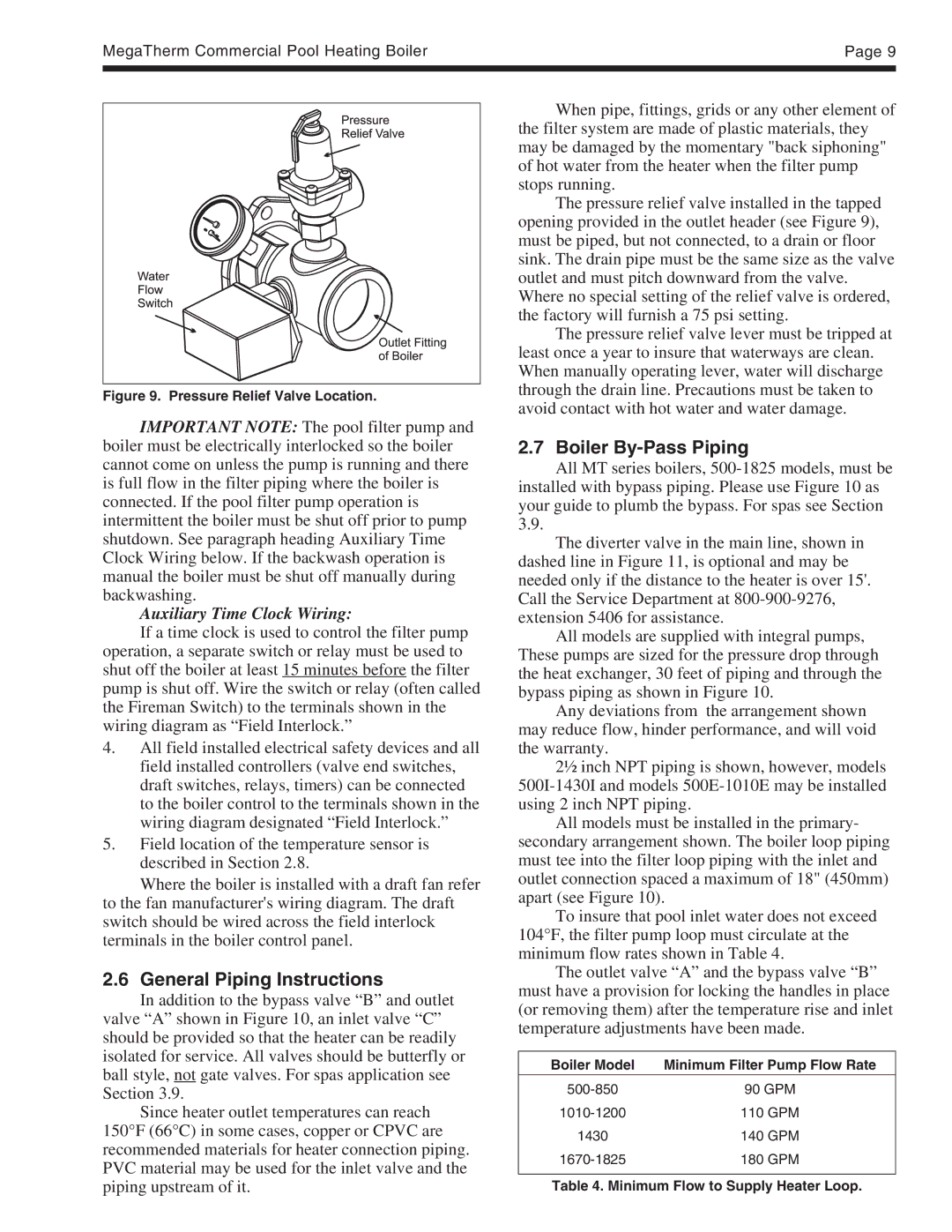

Figure 9. Pressure Relief Valve Location.

IMPORTANT NOTE: The pool filter pump and boiler must be electrically interlocked so the boiler cannot come on unless the pump is running and there is full flow in the filter piping where the boiler is connected. If the pool filter pump operation is intermittent the boiler must be shut off prior to pump shutdown. See paragraph heading Auxiliary Time Clock Wiring below. If the backwash operation is manual the boiler must be shut off manually during backwashing.

Auxiliary Time Clock Wiring:

If a time clock is used to control the filter pump operation, a separate switch or relay must be used to shut off the boiler at least 15 minutes before the filter pump is shut off. Wire the switch or relay (often called the Fireman Switch) to the terminals shown in the wiring diagram as “Field Interlock.”

4.All field installed electrical safety devices and all field installed controllers (valve end switches, draft switches, relays, timers) can be connected to the boiler control to the terminals shown in the wiring diagram designated “Field Interlock.”

5.Field location of the temperature sensor is described in Section 2.8.

Where the boiler is installed with a draft fan refer to the fan manufacturer's wiring diagram. The draft switch should be wired across the field interlock terminals in the boiler control panel.

2.6 General Piping Instructions

In addition to the bypass valve “B” and outlet valve “A” shown in Figure 10, an inlet valve “C” should be provided so that the heater can be readily isolated for service. All valves should be butterfly or ball style, not gate valves. For spas application see Section 3.9.

Since heater outlet temperatures can reach 150°F (66°C) in some cases, copper or CPVC are recommended materials for heater connection piping. PVC material may be used for the inlet valve and the piping upstream of it.

When pipe, fittings, grids or any other element of the filter system are made of plastic materials, they may be damaged by the momentary "back siphoning" of hot water from the heater when the filter pump stops running.

The pressure relief valve installed in the tapped opening provided in the outlet header (see Figure 9), must be piped, but not connected, to a drain or floor sink. The drain pipe must be the same size as the valve outlet and must pitch downward from the valve. Where no special setting of the relief valve is ordered, the factory will furnish a 75 psi setting.

The pressure relief valve lever must be tripped at least once a year to insure that waterways are clean. When manually operating lever, water will discharge through the drain line. Precautions must be taken to avoid contact with hot water and water damage.

2.7 Boiler By-Pass Piping

All MT series boilers,

The diverter valve in the main line, shown in dashed line in Figure 11, is optional and may be needed only if the distance to the heater is over 15'. Call the Service Department at

All models are supplied with integral pumps, These pumps are sized for the pressure drop through the heat exchanger, 30 feet of piping and through the bypass piping as shown in Figure 10.

Any deviations from the arrangement shown may reduce flow, hinder performance, and will void the warranty.

2½ inch NPT piping is shown, however, models

All models must be installed in the primary- secondary arrangement shown. The boiler loop piping must tee into the filter loop piping with the inlet and outlet connection spaced a maximum of 18" (450mm) apart (see Figure 10).

To insure that pool inlet water does not exceed 104°F, the filter pump loop must circulate at the minimum flow rates shown in Table 4.

The outlet valve “A” and the bypass valve “B” must have a provision for locking the handles in place (or removing them) after the temperature rise and inlet temperature adjustments have been made.

Boiler Model | Minimum Filter Pump Flow Rate |

|

|

90 GPM | |

110 GPM | |

1430 | 140 GPM |

180 GPM | |

|

|