Slide Backwash Valve specifications

The Pentair Slide Backwash Valve is a crucial component in the realm of pool maintenance and filtration systems. Designed for efficient water flow management, this valve is ideal for backwashing filters, a process that cleans out the accumulated debris and contaminants from the filtration system, ensuring optimal performance.One of the main features of the Pentair Slide Backwash Valve is its user-friendly design. The slide mechanism allows for smooth operation, enabling users to easily switch between various functions, including filtration, backwashing, and rinsing. The intuitive lever makes it simple for even novice pool owners to operate the valve without confusion.

Another significant characteristic of the Pentair Slide Backwash Valve is its durable construction. Made from high-quality materials, this valve is designed to withstand the rigors of continuous use and the harsh conditions typical of pool environments. The corrosion-resistant body ensures longevity, providing pool owners with a reliable solution for their filtration needs.

Technologically, the valve employs advanced engineering that maximizes flow efficiency. The streamlined internal design minimizes resistance, allowing for faster backwash cycles and reduced water wastage. This feature not only saves time but also conserves water, an increasingly important consideration for environmentally conscious pool owners.

The Pentair Slide Backwash Valve is also compatible with various pool filtration systems, making it versatile for different applications. Whether you have a sand filter, cartridge filter, or a DE filter, this valve can easily integrate with existing setups, enhancing system functionality.

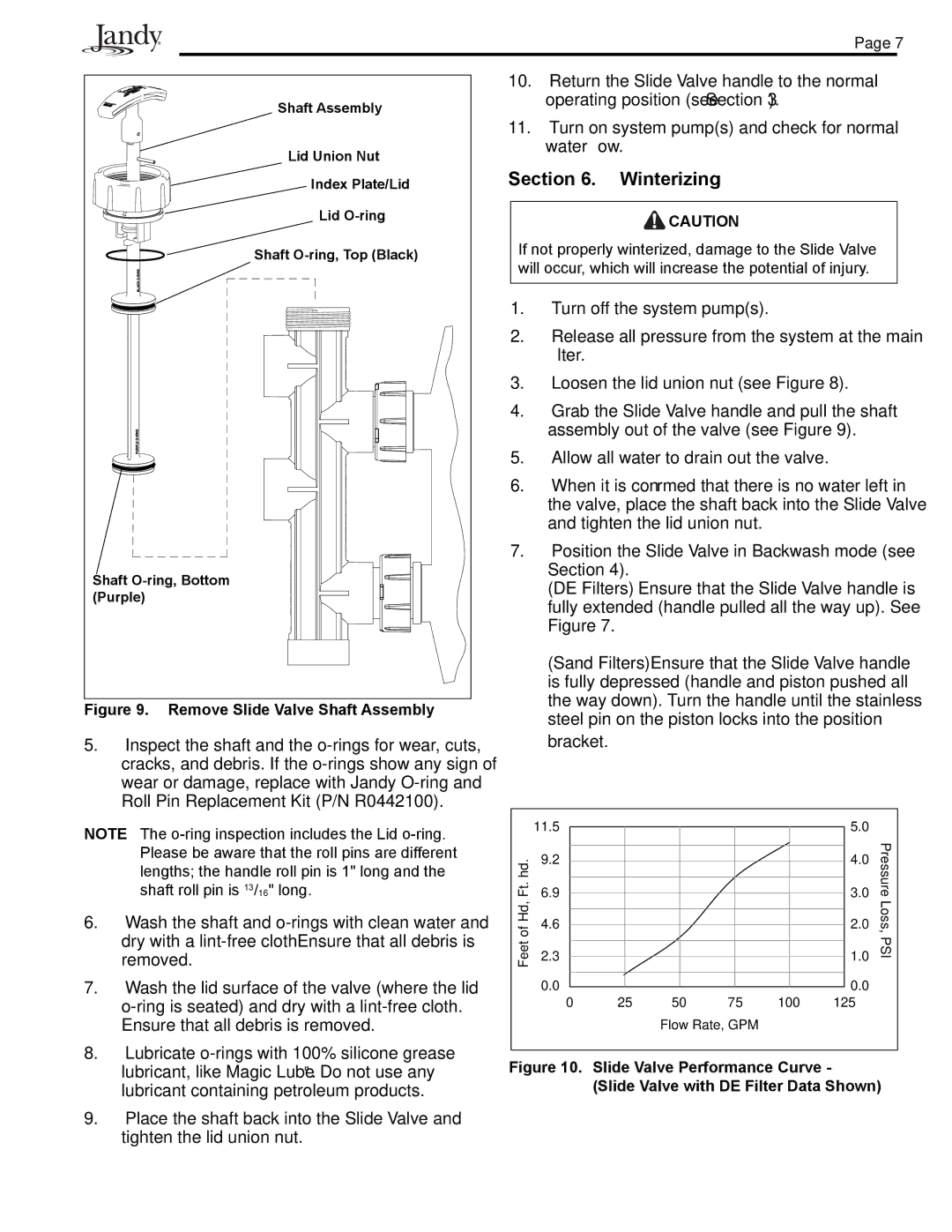

Maintenance is another key aspect of the Pentair Slide Backwash Valve. It is designed for easy disassembly, allowing for straightforward cleaning and maintenance tasks. Regular upkeep ensures that the valve continues to operate efficiently, preventing issues that could arise from buildup and debris.

In summary, the Pentair Slide Backwash Valve stands out for its combination of user-friendly operation, durable construction, advanced technology, compatibility, and low maintenance requirements. Pool owners looking for an effective and efficient solution for their filtration systems will benefit from investing in this high-quality backwash valve, ultimately contributing to cleaner and clearer pool water.